100

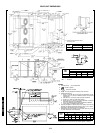

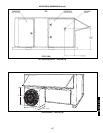

GUIDE SPECIFICATIONS — 548F AND 549B036-120 UNITS (cont)

15. Compressor Cycle Delay:

Unit shall be prevented from restarting for minimum

of 5 min. after shutdown.

*16. Thru-the-Bottom Utility Connectors:

Kit shall provide connectors to permit electrical con-

nections to be brought to the unit through the

basepan.

*17. Fan/Filter Status Switch:

Provides status of indoor (evaporator) fan (ON/OFF)

or filter (CLEAN/DIRTY). Status shall be displayed

over communication bus when used with direct

digital controls or with an indicator light at the

thermostat.

*18. Solid-State Enthalpy Control:

a. For use with Durablade economizer package only.

b. Capable of sensing outdoor-air enthalpy content

(temperature and humidity) and controlling econ-

omizer cut-in point to have minimum heat content

air passing over the indoor coil for most efficient

system operation.

*19. Differential Enthalpy Sensor:

a. For use with Durablade economizer only.

b. Capable of comparing enthalpy content (tempera-

ture and humidity) of outdoor and indoor air and

controlling economizer cut-in point at the most

economical level.

*20. EconoMi$er with Power Exhaust:

Package shall provide control of internal building

pressure. The two-stage system shall exhaust up to

100% of return air (vertical only).

*21. Two-Stage Power Exhaust Accessory for

EconoMi$er:

Power exhaust shall be used in conjunction with

EconoMi$er to provide system exhaust of up to

100% of return air. The power exhaust is a

field-installed accessory (vertical and horizontal

applications).

The individual fans are energized through the end

switches located in the actuator, which will open as

the outdoor-air damper opens. These end switches

are factory set for 30 and 70% of outdoor-air, and

can be set to meet specific job requirements.

*22. Outdoor Air Enthalpy Sensor:

The outdoor air enthalpy sensor shall be used with

the EconoMi$er device to provide single enthalpy

control. When used in conjunction with a return air

enthalpy sensor, the EconoMi$er device will provide

differential enthalpy control. The sensor allows the

EconoMi$er controller to determine if outside air is

suitable for free cooling.

*23. Return Air Enthalpy Sensor:

The return air enthalpy sensor shall be used with the

EconoMi$er device. When used in conjunction with

an outdoor air enthalpy sensor, the EconoMi$er

device will provide differential enthalpy control.

*24. Return Air Temperature Sensor:

The return air temperature sensor shall be used with

the EconoMi$er device. When used in conjunction

with the standard outdoor air temperature sensor,

the EconoMi$er device will provide differential tem-

perature control.

*25. Power Exhaust Auxiliary Transformer:

Field-installed 460v to 230v transformer to provide

power to the 230v power exhaust when attached to a

460v rooftop unit.

*26. Ultra-Violet Germicidal Lamps:

Ultra-violet germicidal lamps are designed to elimi-

nate odor causing mold and fungus that may develop

in the wet area of the evaporator section of the unit.

The high output, low temperature germicidal lamps

are field installed in the evaporator section of the

unit, aimed at the evaporator coil and condensate

pan. The short wavelength ultra-violet light inhibits

and kills mold, fungus and microbial growth. The

lamps have an output rating at 45 F in 400 fpm air-

flow of 120 microwatts/cm

2

at 1 meter.

*27. Hinged Panel Option (549B only):

Hinged panel option provides hinged access panels

for the filter, compressor, evaporator fan, and control

box areas. Filter hinged panels permit tool-less entry

for changing filters. Each hinged panel is perma-

nently attached to the rooftop unit.

28. Emergency Heat Control Package:

When mechanical heating is locked out, auxiliary

heat shall be activated when necessary.

29. Alternate Motors and/or Drives 548F036-060, 090,

120):

Alternate motors and drives shall be factory-installed

to provide additional performance range.

30. High-Static Motor(s) and Drive(s) (548F036-120):

High-static motor(s) and drive(s) shall be factory-

installed to provide and additional performance

range.

50TFQ004-012

548F/549B036-120