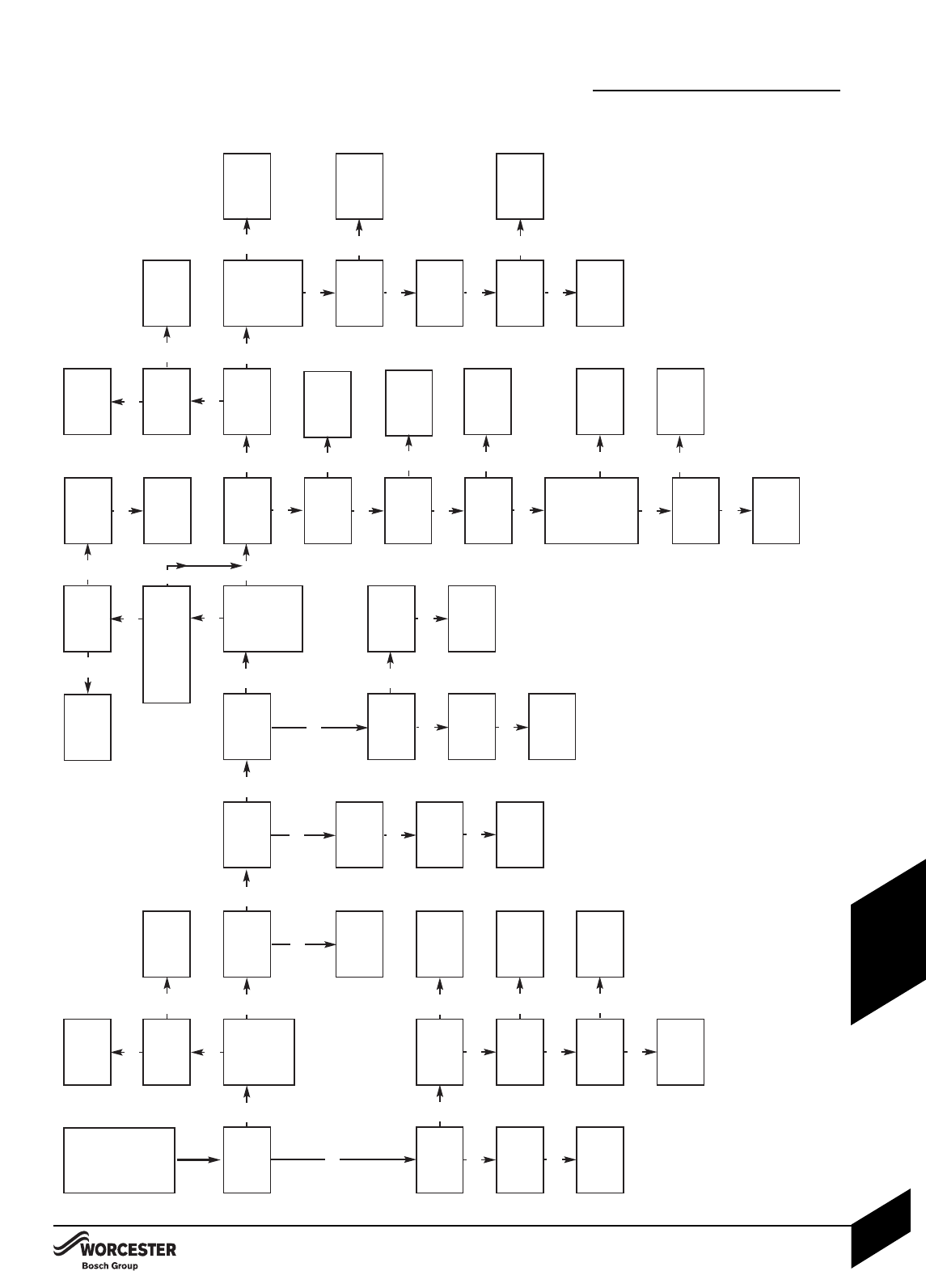

Boiler not

operating

with a

heating /

hot water

demand

Burner

motor runs?

Burner

lights

immediately

motor runs?

230V at

solenoid coil

in purge?

Replace

control box

Replace

pump

230V at

motor?

Motor or

pump

seized?

Replace

motor

capacitor

Motor 40Ω

across

L& N?

L & N to

control box?

Control box

locks out?

Check boiler

controls &

supply

Check

connections/

replace leads

Replace

motor/

pump

Replace

motor

Replace

control box

Lockout

within 1

second?

Replace oil

pump

Oil to

pump?

Drive

coupling

broken?

Pump

produces

pressure?

Replace

transformer

Electrodes

& leads

OK?

230V at

transformer?

Spark

produced?

Lockout

after purge

before oil

solenoid

opens?

Replace

control box

Transformer

lead OK?

Photo cell

lead OK?

Disconnect photo cell,

reset lockout, burner

lights then locks out?

Stray light

on photo

cell?

Combustion

head set

correctly?

Combustion

air setting

correct?

Flame off

and

re-lights?

Nozzle

atomising

fuel?

Replace

photo cell

Photo cell

functional?

If BF

remove

burner

snorkle tube

& retest.

Lights OK?

Replace

photo cell

Replace coil

lead

230V at

solenoid

coil?

Coil lead

OK?

Boiler or

flue blocked

Reseal BF

on

reposition

Replace

control box

Replace

control box

Solenoid

operating?

2.2kΩ

across

solenoid

coil?

Pipe to

nozzle

holder OK?

Oil check

valve OK?

(if fitted)

Replace

nozzle

Replace

solenoid coil

Replace

pump

Replace oil

check valve

(if fitted)

Yes

Yes

Yes

No

No

Yes

Yes

No

No

No

No

No

Yes

Yes

No

No

Yes

No

No

Yes

No

Yes

Yes

Yes

No

Yes

Yes

Yes

Yes

No

No

No

Yes

Yes

Yes

Yes

No

No

No

No

No

Yes

Yes

Yes

Yes

Yes

No

No

No

No

Yes

Yes

Yes

Yes

Replace

lead

No

Reset air

setting

No

Reset

combustion

head

No

FAULT FINDING LOGIC FOR

SATRONIC CONTROL BOX

Note: This chart assumes all wiring within the control box base is correct, if in doubt check the wiring against the diagram on

the base of the control box before replacing any components.

All resistance measurements are actual measured values and some variation is to be expected, therefore measured values

should be similar to but not necessarily identical to the given values.

The operation of the photo cell can be tested by measuring the resistance across the photo cell, it should be a high resistance

(greater than 10MΩ or open circuit) in the dark and low resistance (15kΩ or less) in light.

Burners on balanced flue systems can recirculate flue products resulting in the burner cycling, if this happens check the flue

system integrity and the terminal position.

These fault finding charts are provided to assist competent and suitably qualified engineers to

locate and rectify faults. Whilst every effort has been taken to ensure the information given is

correct and complete we cannot guarantee that every eventuality has been covered.

Worcester, Bosch Group cannot be held responsible for costs incurred by persons not deemed

to be competent.

Measure all 230V tests between

Neutral (N) and the pin, wire or

terminal specified.

FAULT FINDING

INSTALLATION & SERVICING INSTRUCTIONS FOR WORCESTER GREENSTAR HEATSLAVE EXTERNAL 12/18-18/25-25/32

8 716 106 252b (07/06

46

FAULT FINDING

& DIAGRAMS