BALANCED EXTERNAL OILFIT

FLUE OPTIONS

INSTALLATION & SERVICING INSTRUCTIONS FOR WORCESTER GREENSTAR HEATSLAVE EXTERNAL 12/18-18/25-25/32

8 716 113 389b (09/07)

16

PRE -

INSTALLATION

IMPORTANT: The weather seal (supplied)

must be fitted to every flue joint to give

the required level of weather protection.

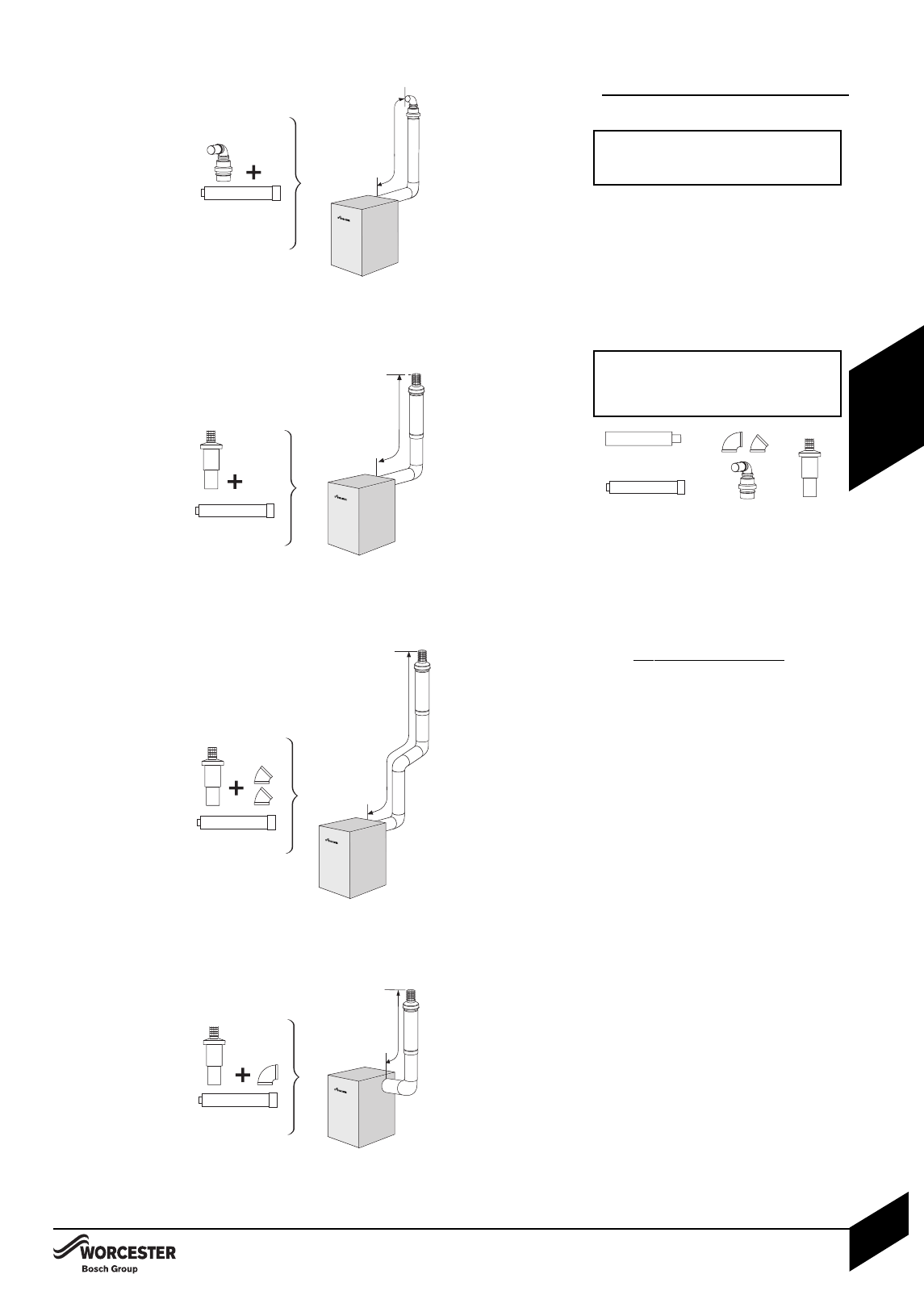

The diagrams (opposite) show the components

used and the maximum flue length (L) for

each flue configuration.

In all cases L is measured from the outside of

the boiler casing.

• To achieve the maximum flue length (L), a flue

section will have to be reduced in length.

• Only the straight flue extensions can be

reduced in length by cutting.

IMPORTANT: All horizontal sections must

rise away from the boiler by 52mm per

metre (3°) to allow the condensate to

drain back to the boiler.

A - Horizontal terminal

B - Straight flue extension

C - Flue bend 90°

D - Flue bend 45°

E - Vertical Terminal Kit (incl. 90° elbow)

F - Horizontal terminal kit (incl. 90° elbow)

Calculating the flue length:

Measure the total flue length required, noting

that the maximum straight flue length including

the terminal is:

Horizontal 80/125mmØ: 4000mm.

Vertical 80/125mmØ / 100/150mmØ (25/32

only): 7000mm.

Then reduce the total straight flue length for

each extra flue bend (excluding the vertical flue

kit 90° elbow) by:

1000mm for 90°

500mm for 45°

Flue Extension lengths:

Horizontal & Vertical: 1000mm overall length.

Effective length when engaged into sockets

within the flue run is 950mm.

Flue Terminal lengths:

Horizontal 80/125mmØ: 720mm

Vertical 80/125mmØ: 1080mm + cage

* Rear exit only.

** Horizontal flue runs should be kept as

short as possible.

L = 6000mm

125mmØ x4

L

L = 2000mm

125mmØ x2

B

D

D

B

E

E

B

C

D

A

L

F

F

L = 7000mm

125mmØ x5

L

E

B

L = 6000mm

125mmØ x4

B

E

L

C

BALANCED EXTERNAL OILFIT

FLUE OPTIONS

High level horizontal terminal (rear outlet)

*

**

Vertical terminal (rear outlet)

Vertical terminal (rear outlet)

Vertical terminal (side outlet)

**

**

**