STARTING THE APPLIANCE

INSTALLATION & SERVICING INSTRUCTIONS FOR WORCESTER GREENSTAR HEATSLAVE EXTERNAL 12/18-18/25-25/32

8 716 113 389b (09/07)

32

COMMISSIONING

STARTING THE APPLIANCE

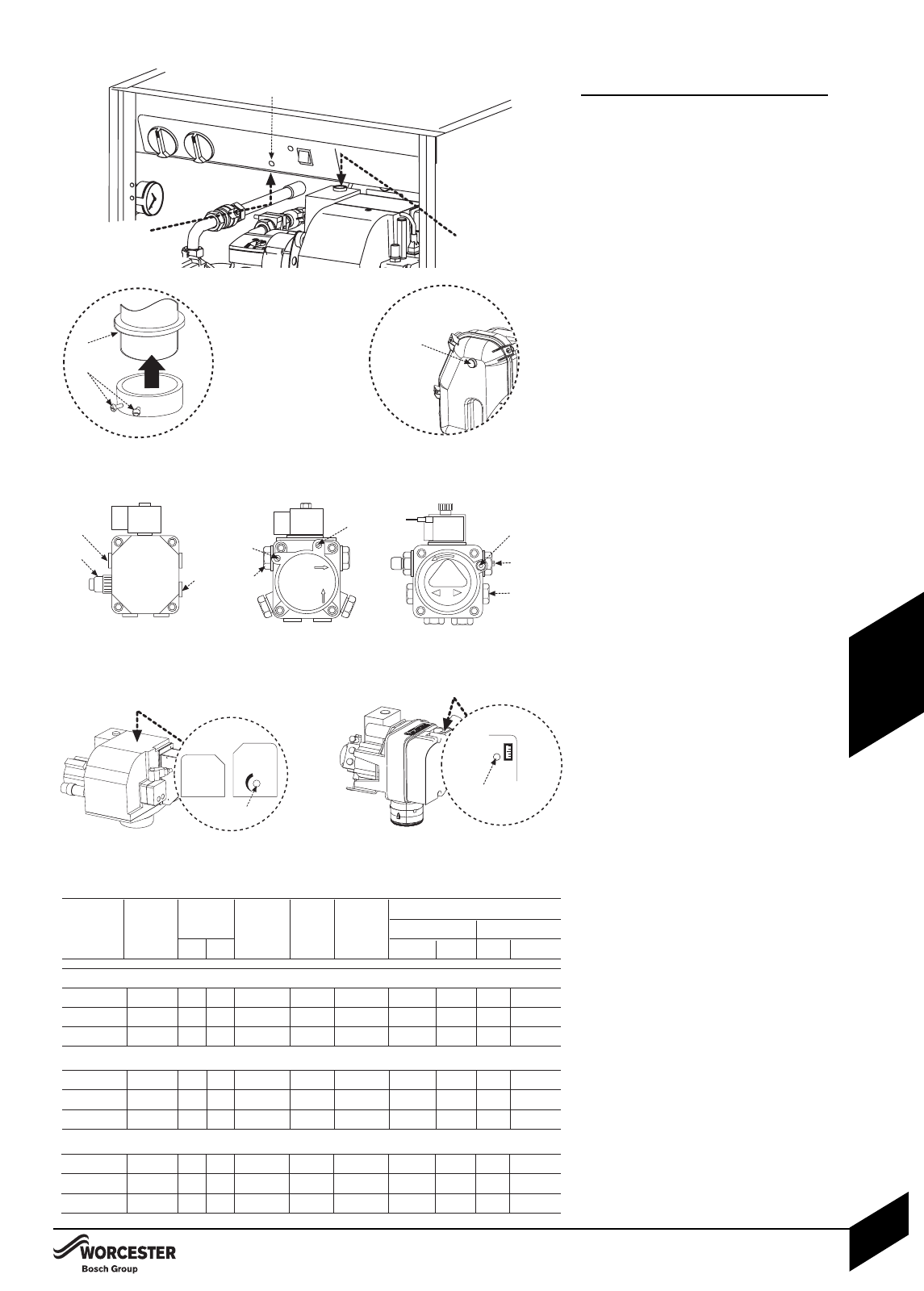

2Remove plastic cover from the burner casing

(there is no plastic cover on the Riello burner).

Fit a suitable pressure gauge to port (A) on

the oil pump.

Adjust the air shutter (L) and pump pressure

(B) as shown in the table opposite. The

burner should ignite following a pre-ignition

period of approx. 15 seconds.

Boiler lockout indicator on:

If the burner fails to establish a normal firing

pattern or flame failure occurs the flame

monitoring photocell mounted in the burner

body will alert the burner control box to shut

the burner down and provide a safe lockout

state indicated by the illumination of the

lockout indicator (E).

Wait 2 minutes then press the lockout

reset button (D) to initiate another start

sequence.

Repeat procedure until a flame is established.

3Start and run for 3 minutes then switch off.

Check for after-spurting from the nozzle,

indicated by oil saturation on the combustion

head (F).

If after-spurting occurs:

Release the burner retainers.

Remove the burner, combustion head (F).

and electrodes, hold the burner vertical

to unscrew the nozzle and fill the nozzle

holder with oil.

Refit nozzle, electrodes, combustion

head (F) and the burner.

Restart and run for 3 minute intervals until

after-spurting stops.

4Start and run for 20 minutes.

Remove sampling point plug (K) to check

the smoke reading is between 0-1. If the

smoke level is above 1, check the combustion

settings are correct and the oil nozzle is in

good condition.

Note; smoke readings may be inaccurate until

the smoke from burning organic binder in the

access door insulation has ceased.

Check the CO

2

levels and adjust the air

shutter (L) setting according to the table

opposite.

Check the flue gas temperature is close to

the values shown in the table.

If the flue gas temperature is too high and the

baffles are correctly fitted, then reduce the oil

pump pressure (B) 5-10p.s.i. to compensate

for nozzle variations.

Turn off the electrical supply.

Isolate the oil supply to the burner.

Remove the oil pressure gauge.

Refit the blanking plug (A).

Check and rectify any oil leaks.

5Switch on the oil supply.

Switch on the electrical supply.

Restart the boiler and run for 5 minutes.

Recheck the CO

2

levels and if required,

adjust the air shutter setting (L) to obtain

the correct CO

2

level.

5

L

A

B

C

A - Bleed & pressure gauge port

B - Pressure adjustment

C - Vacuum gauge port

2

4

K

D

12/18 & 18/25

(under control box)

DANFOSS

BFP 11 L3 OIL PUMP

A

B

C

SUNTEC

AS47C OIL PUMP

%CO

2

NOMINAL BOILER RATING AT NORMAL OPERATING

TEMPERATURE USING 28sec KEROSENE:

NOZZLE

12/18 - Bentone Sterling 40 Burner:

OIL PUMP

PRESSURE

(p.s.i.)

FUEL

FLOW RATE

Kg/h l/h

APPROX.

FLUE GAS

TEMP °C

APPROX.

AIR

SETTING

APPLIANCE

INPUT OUTPUT

kW Btu/hr kW Btu/hr

0.35 80°SR

0.45 80°S

0.50 80°ES

115

115

140

1.04

1.29

1.55

1.32

1.63

1.96

66

70

73

11.5

12.0

12.5

2.5

4.5

5.25

42300

52900

63500

12

15

18

40900

51200

61400

12.4

15.5

18.6

3

G

F

L

RIELLO

RDB OIL PUMP

C

B

A

25/32 - Riello RDB Burner:

0.75 60°ES

0.75 60°ES

0.85 60°ES

105

140

150

2.15

2.45

2.75

2.72

3.1

3.48

78

80

83

11.5

12.0

12.5

3.0

4.0

5.0

87000

99300

111600

25

28.5

32

85300

97200

109200

25.5

29.1

32.7

18/25 - Bentone Sterling 50 Burner:

0.50 80°EH

0.55 80°EH

0.65 80°EH

130

145

150

1.56

1.86

2.17

1.98

2.36

2.75

72

79

82

11.5

12.0

12.5

4.25

6.0

8.0

63500

75750

88000

18

21.5

25

61400

73400

85300

18.6

22.2

25.8

D

25/32

(on top of burner

control box)

E