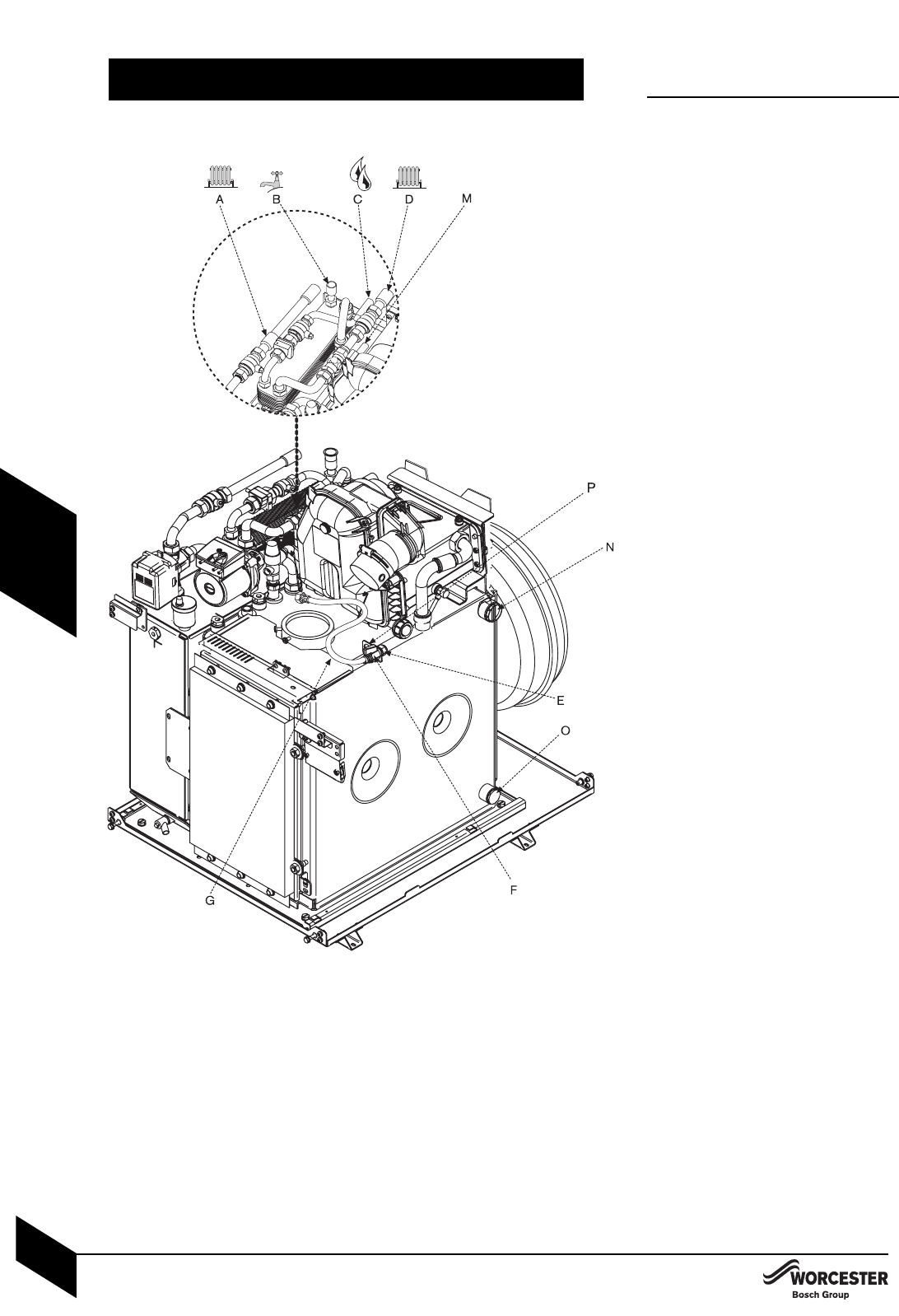

PIPEWORK CONNECTIONS

INSTALLATION & SERVICING INSTRUCTIONS FOR WORCESTER GREENSTAR HEATSLAVE EXTERNAL 12/18-18/25-25/32

8 716 113 389b (09/07)

23

INSTALLATION

PIPEWORK CONNECTIONS

A - CH flow 22mmØ copper (28mmØ on

25/32 models)

B - DHW flow 22mmØ

C - Water main inlet 15mmØ

D - CH return 22mmØ copper (28mmØ on

25/32 models)

E - 10mmØ oil supply pipe connection

F - Oil isolating valve (10mmØ)

G - Flexible oil hose

N - Optional open vent/air vent

O - Drain/optional feed and expansion

P - Fixing point for optional return oil pipe

WATER CONNECTIONS:

All service pipes into the property must pass

through the services duct.

Insulate all the system/supply pipes where

the pipes pass through the duct with at least

22mm insulation around the pipes.

Remove the transit bungs from the pipework

connections on the boiler.

NOTE: that surplus water may be present due

to factory testing.

Ensure all pipework is clean.

Align water pipework through the 100mm Ø

duct and connect, ensuring that the

expansion tank and control box fit correctly

before permanently connecting the pipework.

Check that all unused sockets have been

capped.

OIL SUPPLY CONNECTIONS:

NOTE: Oil filters and de-aeration devices are

not to be fitted within the casing and the fire

valve body must be at least 1 metre from the

external casing.

Route the oil supply pipe through the

appropriate casing hole as required and

connect to the isolating valve (F) and ensure

the valve is closed.

Connect the flexible oil hose (G) to the

isolating valve (F).

Pass the fire valve sensor through the most

appropriate casing hole and locate the

capillary in the cut out at the bottom of the

hole.

Clip the sensor into the clip provided at the

rear of the control box.

Rotate the cover plate and seal so it does not

cover the capillary, then secure with the screws

provided.

CAUTION: ISOLATE THE OIL & WATER MAINS SUPPLY BEFORE STARTING ANY

WORK AND OBSERVE ALL RELEVANT SAFETY PRECAUTIONS.