Instruction Manual – Model CF2500/CF3500 Oil Burner

9

Form 6104 BCF-35-R0699

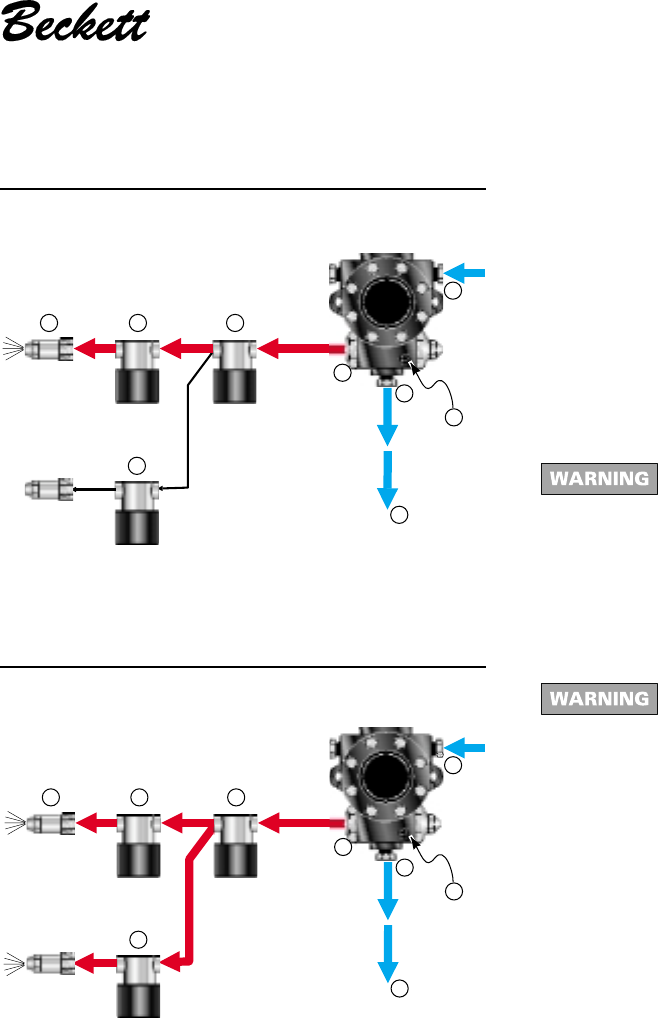

Figure 9a

Two-pipe oil flow, one nozzle, low fire, “H” pump

• Install two high-quality shutoff valves in accessible loca-

tions on the oil supply line. Locate one valve close to the

tank. Locate the other valve close to the burner, upstream

of the fuel filter.

❏ Burner fuel flow

• One-pipe systems – See Figure 8 for the fuel flow paths

for high-fire and low-fire operation. Oil supply connects to

one of the fuel unit Inlet ports.

Do not install by-pass plug in a one-pipe

system. Could cause unit seal failure, oil

leakage and potential fire and injury hazard if

ignored.

• Two-pipe systems – See Figure 9 for the fuel flow paths

for high-fire and low-fire operation. Oil supply connects to

one of the fuel unit Inlet ports. Oil return connects to the

fuel unit Return port.

By-pass plug must be installed in a two-pipe

system. Failure to comply could cause unit

seal failure, oil leakage and potential fire and

injury hazard.

• Low-fire/high-fire operation – The fuel unit nozzle port

pressure is factory set at 300 psig.

• At high fire, full pressure (300 psig) is applied at both

oil nozzles, causing full input.

• At low fire, full pressure (300 psig) is applied at one

nozzle, causing reduced input.

Figure 9b

Two-pipe oil flow, two nozzles, high fire, “H” pump

a Return port

b Nozzle port

c Oil valves

d Nozzle & adapter

g Inlet port

k Return line to oil tank

p Air bleed valve

Legend (for Figures 8a, 8b, 9a and 9b)

3512

d

200 psig

to

300 psig

cc

c

k

200 psig

to

300 psig

b

g

a

p

3513

d

200 psig

to

300 psig

cc

c

k

200 psig

to

300 psig

200 psig

to

300 psig

b

g

a

p