7

275

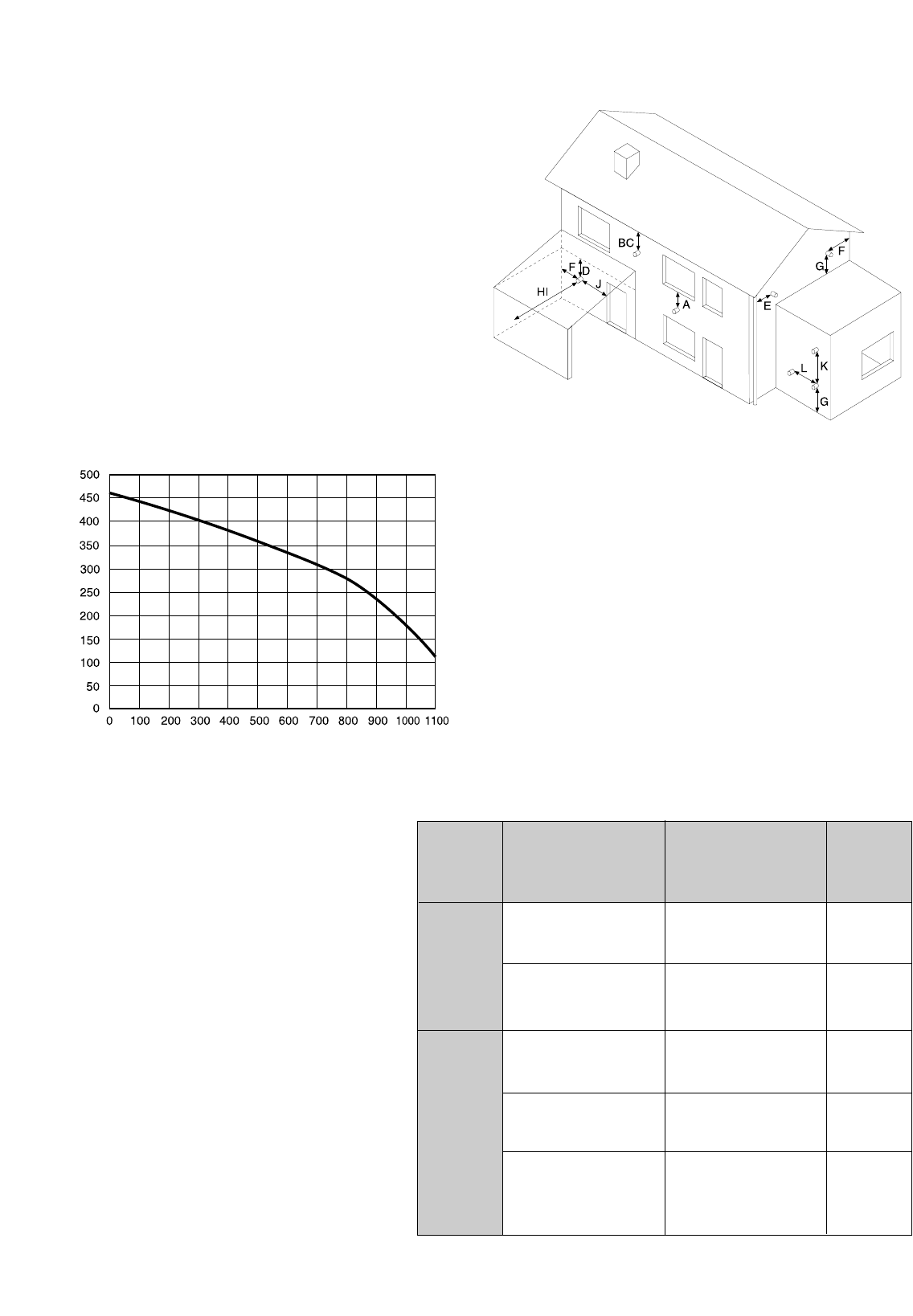

In F

IG. 2.11 below, several different types of flue systems are shown.

For additional information regarding the flue accessories, please

consult the Flue Pipe Accessories manual.

Coaxial

Systems

Twin Pipe

Systems

Exhaust Type

C

13

B

33

outlet of fumes in

chimney or exhaust flue

C

13

, C

33

, C

43

C

53,

C

83

B

23

Maximum Extension

Exhaust/Air

(m)

4

4

31 (S1=S2)

55 (S1+S2)

54 (S2)

Diameter

of Pipes

(mm)

Ø 60/100

Ø 60/100

Ø 80/80

Ø 80/80

Ø 80

TERMINAL POSITION mm

A - Directly below an open window or other opening 300

B - Below gutters, solid pipes or drain pipes 75

C - Below eaves 200

D - Below balconies or car-port roof 200

E - From vertical drain pipes and soil pipes 75

F - From internal or external corners 300

G - Above ground or below balcony level 300

H - From a surface facing a terminal 600

I - From a terminal facing a terminal 1200

J - From an opening in the car port

(e.g. door, window) into dwelling 1200

K - Vertically from a terminal in the same wall 1500

L - Horizontally from a terminal in the same wall 300

FIG. 2.6

2.9. FLUE CONNECTIONS

FLUE SYSTEM

The provision for satisfactory flue termination must be

made as described in BS 5440-1.

The appliance must be installed so that the flue terminal is

exposed to outdoor air.

The terminal must not discharge into another room or

space such as an outhouse or lean-to.

It is important that the position of the terminal allows a

free passage of air across it at all times.

The terminal should be located with due regard for the

damage or discolouration that might occur on buildings in

the vicinity.

In cold or humid weather water vapour may condense on

leaving the flue terminal.

The effect of such “steaming” must be considered.

If the terminal is less than 2 metres above a balcony,

above ground or above a flat roof to which people have

access, then a suitable terminal guard must be fitted.

When ordering a terminal guard, quote the appliance

model number.

A suitable terminal guard is available from:

TOWER FLUE COMPONENTS

Morley Road

Tonbridge

Kent TN9 1RA

R

ESIDUAL HEAD OF THE BOILER

expansion and add an additional sealed expansion vessel with

adequate capacity.

MAINS WATER FEED - CENTRAL HEATING:

There must be no direct connection to the mains water supply

even through a non-return valve, without the approval of the Local

Water Authority.

F

ILLING:

A temporary method for initially filling the system and replacing

lost water during servicing and initial filling (in accordance with

Water Supply Byelaw 14), is provided as an integral part of the

connection kit (see F

IG. 2.5). The flexible hose must be removed

once the system has been filled. The D.H.W. inlet valve on the

connection kit has two positions, one for winter and one for the

summer. This enables the flow-rate through the appliance to be

adjusted so that a sensible D.H.W. temperature may be achieved

throughout the year.

D

OMESTIC W

ATER

The domestic water must be in accordance with the relevant

recommendation of BS 5546:1990. Copper tubing to BS EN

1057:1996 is recommended for water carrying pipe work and

must be used for pipe work carrying drinking water.

The minimum acceptable spacing from the terminal to obstructions

and ventilation openings are specified in Fig. 2.6