88

88

8

NO. SUGGESTED ITEMS FOR INSTALLATION

1 Short pipe nipple and pair of boiler loop tees in piping

between system supply and return. One set per each

group of boilers

2 Boiler pipe loop. See piping sizing data above.

3 Boiler circulator. See pump sizing data above.

4 Thermometer.

5 Theraltimeter.

6 Plug cock to control flow rate.

7 Safety flow switches. For interlock with other systems or

instead of low water cutoff.

8 Relief valve.

9 With one -300, -399 or -420 item 9 is - sensing

element of remote control.

With a group of -300's, -399's or -420's, item 9 is - for

1st. boiler, the sensing element as above. For additional

boilers, install a 2nd. limit control if required by local codes.

With any -520, -610 or 670 boilers, install 2nd. limit control

here if required by local code.

BOILER INLET - OUTLET SIZES

10 HWB-300 - 1-1/4", HWB-399 - 1-1/2", HWB-420-1-1/2",

HWB-520 & HWB-610 - 2". Canadian Models

10 HW-300 - 1-1/4", HW-399 - 1-1/2", HW-420-1-1/2",

HW-520 & HW-670 - 2". U.S. Models

MINIMUM BRANCH SIZES TO BOILERS

11 HWB-300 - 1-1/4" HWB-520, 610 (Single boiler

HWB-399 - 1-1/2" per pump) 2"

HWB-420 - 1-1/2" Canadian Models

11 HW-300 - 1-1/4" HW-520, 670 (Single boiler

HW-399 - 1-1/2" per pump) 2"

HW-420 - 1-1/2" U.S. Models

12 Flow control valve. Required only if flow rate of system

primary is excessive for size of boiler branch tees or if

chilled water main is above boilers.

13 System supply temperature thermometer.

14 Boiler headers for three (3) boilers can be larger than pipe loop,

if desired, to aid in balancing.

The system flow rate is selected to give the desired system

temperature drop - depending on the design criteria.

The boiler generator flow rates, on the other hand, should be

selected to give the temperature rise through the generator that is

both economical and offers the best generator efficiency.

The boiler temperature rise is normally between 10

0

C and 20

0

C

(20

0

F and 40

0

F). The system temperature that will be introduced

to the boiler (inlet temperature) plus the selected boiler temperature

rise selected from PUMP AND PIPE SIZING DATA should not exceed

the high limit control setting of 115

0

C (240

0

F).

There should be a relation of the minimum system load to the size

boiler selected as the first firing or base boiler. This will stabilize

operation during minimum load periods.

B. Commercial Boiler Replacements

Application of

LINEAR-TEMP

®

to a commercial boiler replacement

with an old multiple pump installation is an excellent way to

modernize the system. The A. O. Smith boiler(s) should be

installed on a pipe loop with a separate circulating pump selected

from PUMP AND PIPE SIZING DATA TABLE.

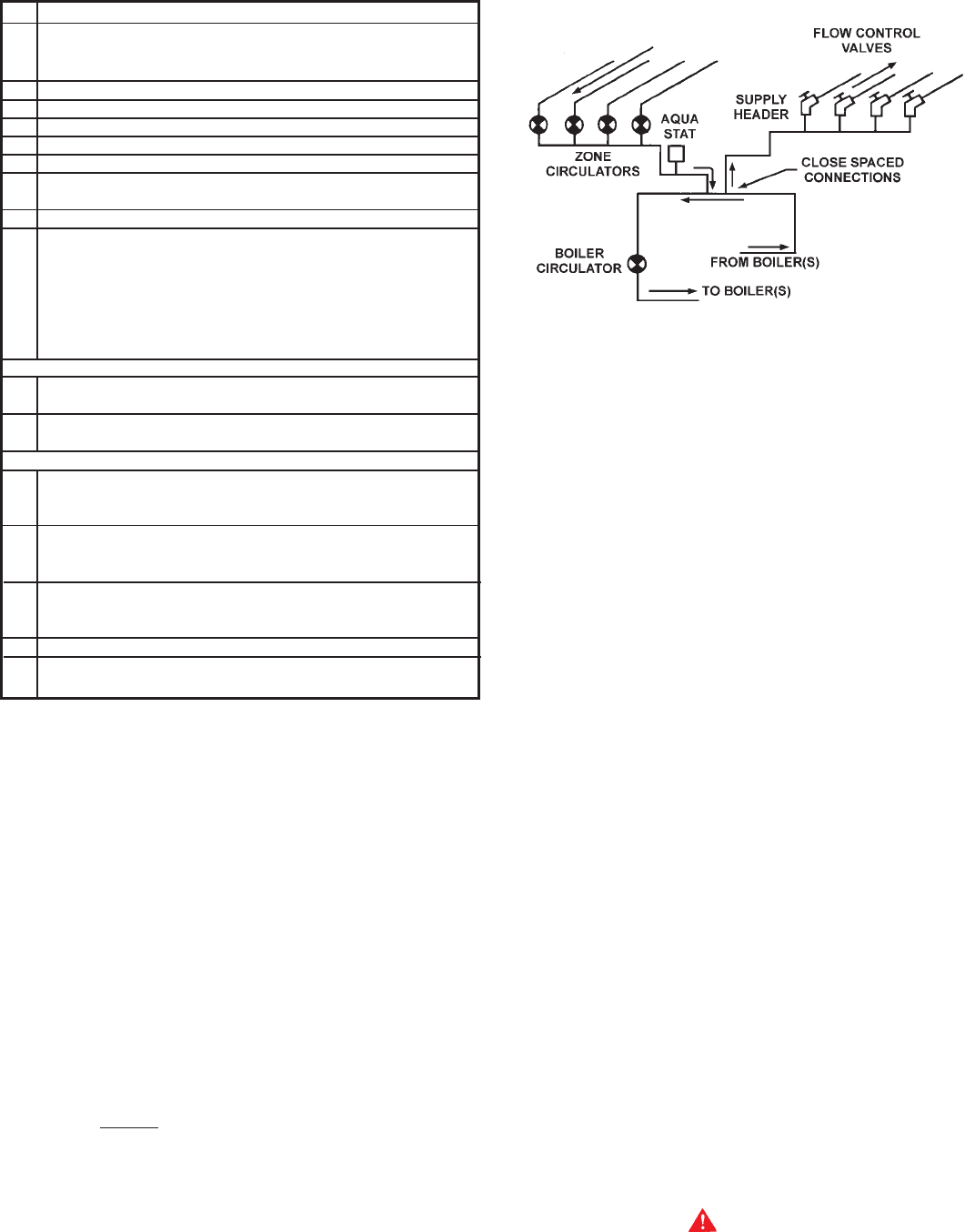

Figure 3 shows a line drawing of how the system headers should

be connected to the pipe loop installed with the replacement

boiler(s). Make-up water connections and accessories are not

shown.

SCHEMATIC OF THE LINEAR-TEMP

®

SYSTEM

FIGURE 3

Supply and return headers of the old system should be connected

to the boiler loop with a pair of tees set close together. The boiler

loop pump and the boiler(s) should be wired to operate only when

any of the system pumps are in operation. The number of zone

pumps that may be in operation at any particular time will take their

required flow rate out from the first tee in the boiler piping. This

water will be circulated through the proper branches from the supply

header to the zones calling for heat. The water will be brought

back to the return header and then into the second tee in the boiler

pipe loop. There will be no conflict between the boiler pump and

the zone pumps when the two tees in the boiler loop are placed

close together.

Normal use of flow control valves is required to prevent cross

circulation of zones as with any multiple pump system. Flow control

is not required on boiler circuit.

Attention should be given to balancing gas inputs and water flow

rates. Large systems with multiple boilers should include main

water temperature control (with or without outdoor reset) to stage

the boilers on and off in relation to the load on the system.

3. WATER SUPPLY LINE

These boilers can be used ONLY in a forced circulation hot water

heating system. Since most forced circulation systems will be of

the closed type, install the water supply line as shown on piping

diagrams, fig. 1 or 2.

Fast filling of large pipe, old radiator installations and pressure

purging of series loop systems (where high pressures are not

available) requires bypassing of the pressure reducing valve.

Generally, pressure purging is not possible with a well pump

system. High point air venting is essential.

If the system is of the open type, a pressure reducing valve will not

be required as the water supply to the system will be controlled by

a manually operated valve. An overhead surge tank is required.

4. EXPANSION TANK

CAUTION

A closed system will exist if a check valve (without bypass), pressure

reducing valve (without bypass), or a water meter (without bypass)

is installed in the cold water line between the water heater and

street main (or well).