1313

1313

13

After it has been determined that each appliance remaining

connected to the common venting system properly vents when

tested as outlined above, return doors, windows, exhaust fans,

fireplace dampers and any other gas burning appliance to their

previous conditions of use.

Any improper operation of the common venting system should be

corrected so the installation conforms with the latest edition of

CAN/CGA B149.1-00 (latest edition). When resizing any portion of

the common venting system, the common venting system should

be resized to approach the minimum size as determined using

the appropriate tables in Appendix G in CAN/CSA B149.1-00.

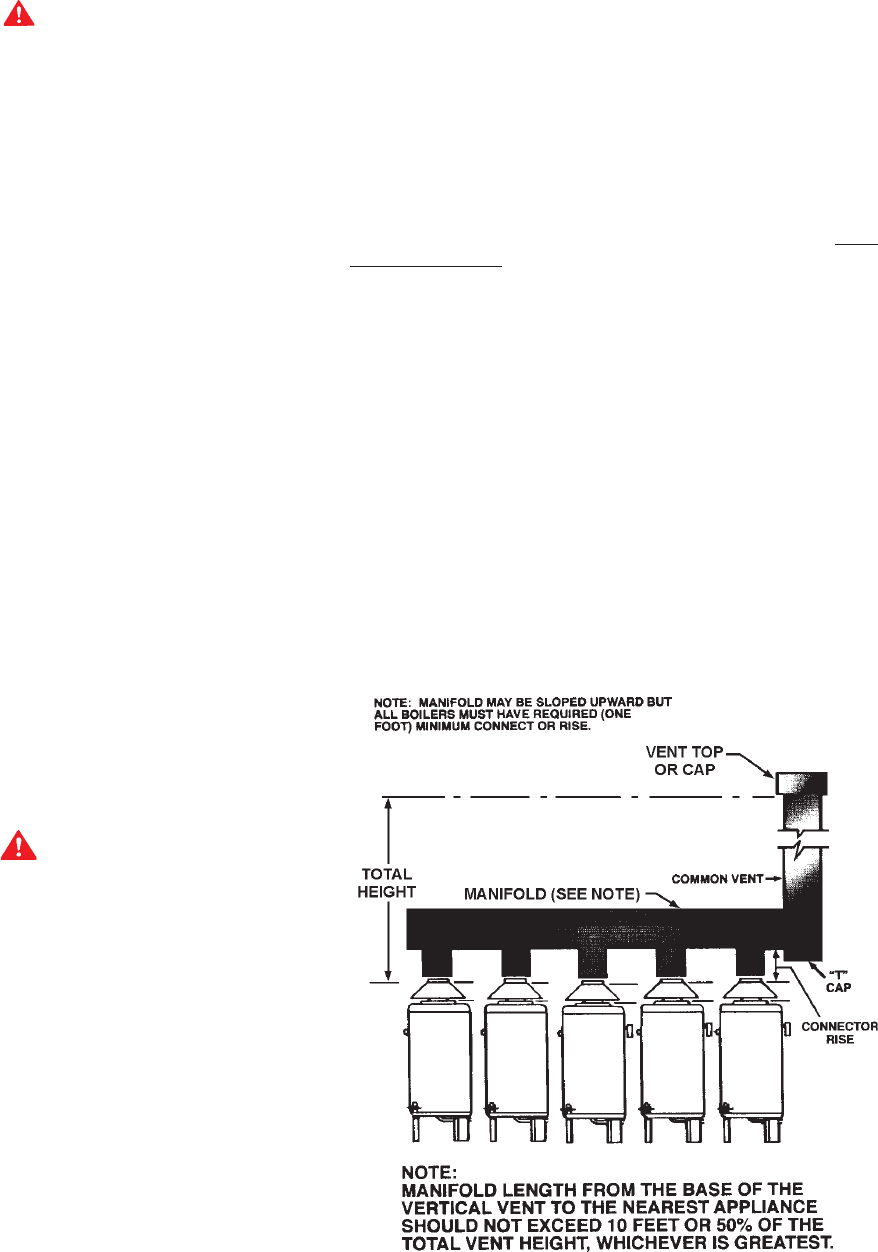

4. MULTIPLE VENT TABLE

Table 9 has been compiled to show the material sizes in a Type B

doublewall combined vent system. Refer to

CAN/CSA B149 .1-00 (latest edition), or the ASHRAE

1983

Equipment Volume for further information.

A combined vent system is one in which two or more boilers at one

level are attached to a common vent.

In order to use table 9, the connector rise and total vent height

must be known. Connector rise is vertical distance from the draft

hood outlet to the point where the manifold connection is made.

Total vent height is the least vertical distance from a draft hood

outlet to the top of the vent. Local codes or utility requirements

often govern termination height. ULC listed doublewall gas vents,

up through 24" (610mm) diameter, can be installed in heated and

unheated areas and can pass through floors, ceilings, partitions,

walls and roofs, provided the required one inch clearance is

observed. These vents should be installed in accordance with

CAN/CSA B149.1-00 (latest edition).

EXAMPLE SHOWING USE OF THE HWB/HW-610 COMBINED VENT

SIZING TABLE 9

FIGURE 8

Where a continuous or intermittent back draft is found to exist the

cause must be determined and corrected. A special vent cap may

be required. If the back draft cannot be corrected by the normal

methods or if a suitable draft cannot be obtained, a blower type

flue gas exhauster may be employed to ensure proper venting and

correct combustion if permitted by local codes.

WARNING

FAILURE TO CORRECT BACK DRAFTS WILL CAUSE AIR

CONTAMINATION AND UNSAFE CONDITIONS.

Vent connectors serving appliances vented by natural draft shall

not be connected into any portion of mechanical draft systems

operating under positive pressure.

3. CONNECTING BOILER TO A COMMON VENT

Do not connect the boiler to a common vent or chimney with solid

fuel burning equipment. This practice is prohibited by many local

building codes as is the practice of venting gas fired equipment to

the duct work of ventilation systems.

Where a separate vent connection is not available and the vent

pipe from the boiler must be connected to a common vent with oil

burning equipment, the vent pipe should enter the common vent

or chimney at a point ABOVE the flue pipe from the oil fired unit.

Where two or more appliances vent into a common vent connector

or manifold, the area of the common vent or vent connector should

at least equal the area of the largest vent connector plus 50% of

the areas of the additional draft hood outlets.

When removing a boiler from a system with a common vent, use

the following steps:

Be sure the other appliances connected to the common vent are

not in operation.

Seal any unused openings in the common venting system.

Visually inspect the venting system for proper size and horizontal

pitch and determine there is no blockage or restriction, leakage,

corrosion and other deficiencies which could cause an unsafe

condition.

WARNING

Ensure sufficient supply and ventilation air. Under no circumstances

should the equipment room where the boiler is installed ever be

under negative pressure. Insufficient air supply can interfere with

combustion and ventilation of this boiler resulting in unsafe

conditions.

Insofar as is practical, close all building doors and windows and

all doors between the space in which the appliances remaining

connected to the common venting system are located and other

spaces of the building. Turn on clothes dryers and any appliance

not connected to the common venting system. Turn on any exhaust

fans, such as range hoods and bathroom exhausts, so they will

operate at maximum speed. Close fireplace dampers.

Place in operation the appliance being inspected. Follow the

lighting instructions. Adjust thermostat so appliance will operate

continuously.

Test for spillage at the draft hood relief opening after five minutes

of main burner operation. Use the flame of a match or candle.