5151

5151

51

• If lamp does not light when reset button is depressed, attach

the test flashlight leads to the protector switch terminals. If

lamp does not light, switch is defective and must be replaced.

• If lamp does light, the leads are bad and must be repaired or

replaced.

CHECKING AND ADJUSTING THE INPUT

1. Follow steps 1 thru 6 of the OPERATING INSTRUCTIONS.

2. Attach a pressure gauge or a manometer to the manifold

pressure tapping and refer to table 8 for correct manifold

pressure.

3. Follow steps 7 thru 11 of the OPERATING INSTRUCTIONS.

4. Use this formula to “clock” the meter. Be sure that other gas

consuming appliances are not ON during this interval.

3600 x H = Btuh

T

Btuh = The approximate actual input rate.

T = Time in seconds to burn one cubic foot of gas.

H = Heating value of the fuel gas in Btu per cubic foot of

gas.

EXAMPLE:

T = 9.0 seconds/ft

3

H = 1050 Btu/ft

3

(natural gas)

Btuh = ?

Gas flow through meter:

3600 x 1050 = 420,000 Btuh

9.0

Small changes in the input rate may be made by adjusting the

manifold pressure, see GAS PRESSURE REGULATORS. Under

no circumstances should you exceed the maximum input rate for

the boiler given in table 2.

5. Repeat steps 1 thru 6 of the OPERATING INSTRUCTIONS.

6. Remove the pressure gauge or manometer from the manifold

pressure tapping. Replace the screw-in plug in the manifold

pressure tap.

7. Repeat steps 7 thru 11 of the OPERATING INSTRUCTIONS.

The boiler will resume normal operation.

When the boiler is operating at full capacity, or full gas input, it

should consume 1 cu. ft. of gas in approximately the time

indicated in table 10.

TABLE 10

CONSUMPTION RATE

(Refer to Operating at Full Input or Full Capacity)

TIME TO CONSUME 1 CU. FT.

Heating OF GAS (SECONDS)

Type Value HWB/ HWB/ HWB/ HWB/ HWB/ HWB/

Gas Btu/Ft.^3 HW-300 HW-399 HW-420 HW-520 HW-610 HW-670

Natural 1050 12.6 9.5 9.0 7.3 6.2 5.7

Propane 2500 30.0 22.6 21.4 17.3 14.8 13.4

IMPORTANT

UNDER NO CIRCUMSTANCES SHOULD THE GAS INPUT

EXCEED THE INPUT SHOWN ON THE BOILER MODEL AND

RATING PLATE. OVERFIRING COULD RESULT IN DAMAGE OR

SOOTING OF THE BOILER.

Minor variances from input on rating

plate can be corrected by adjustment of gas pressure regulators

described in GAS PRESSURE REGULATORS section of this

manual.

The inlet gas pressure must not exceed or be less than the values

shown on rating plate.

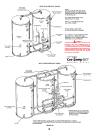

CONTROL SETTINGS

MODEL HW-300, HW-399, HW-420, HW-520, HW-610 & HW-670

The high limit is a safety device wired in series with the ignition

system. Set the high limit control to approximately 10

0

F above the

maximum designed system temperature. If the boiler outlet water

temperature should exceed the high limit setting, the main gas

valve will close but the circulator will continue to operate. Maximum

adjustable setting is 115

0

C (239°F) cut-out with a 3

0

C (5

0

F) to 25

0

C

(45

0

F) adjustable differential, fig. 45.

FIGURE 45

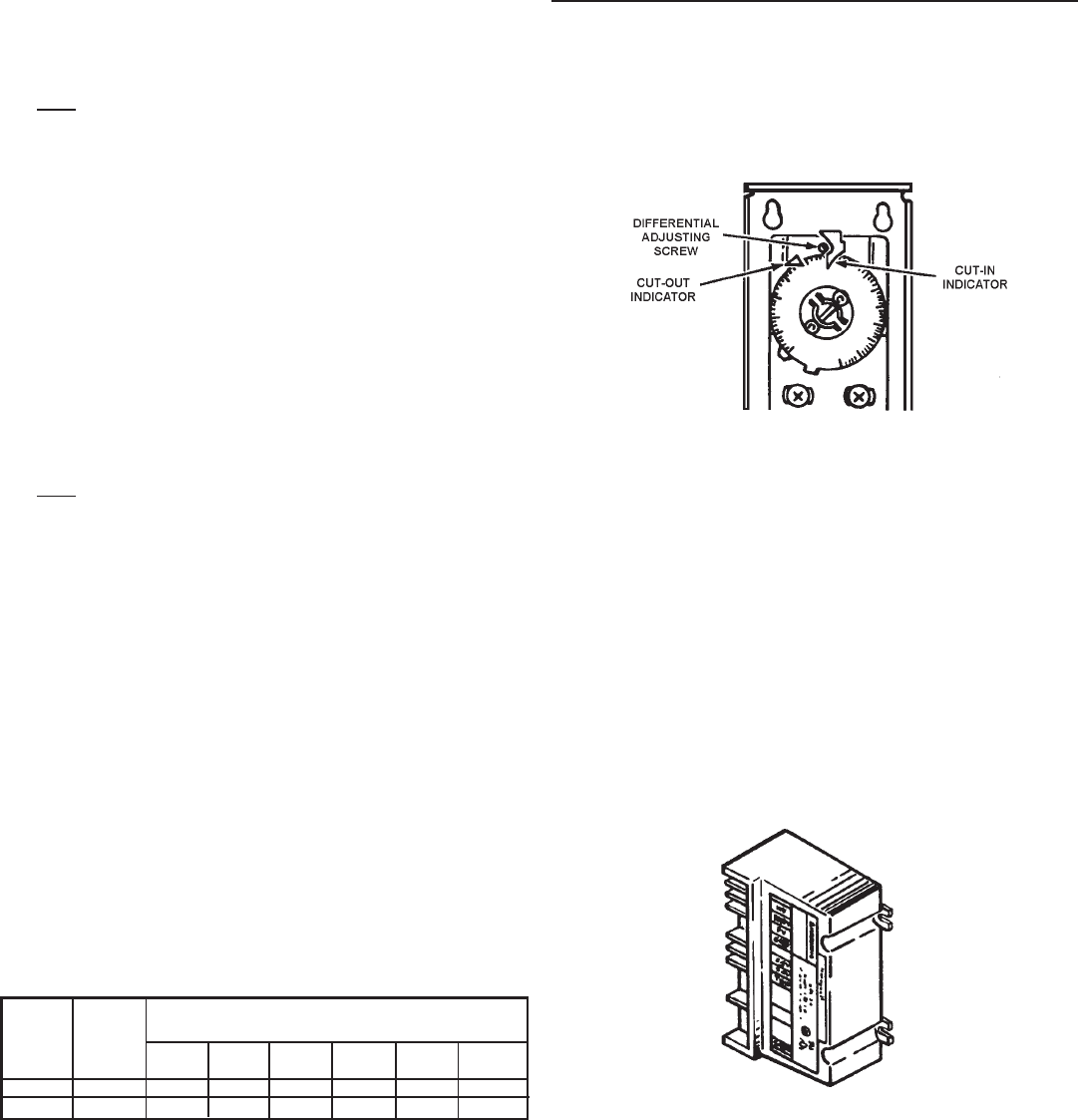

ELECTRONIC INTERMITTENT PILOT

IGNITION CONTROL

The solid state ignition control, fig. 46, ignites the pilot burner gas

by creating a spark at the pilot assembly. Pilot gas is ignited and

burns during each running cycle. The main burner and pilot gases

are cut off during the “OFF” cycle. Pilot gas ignition is proven by the

pilot sensor. Main burner ignition will not occur if the pilot sensor

does not first sense pilot ignition.

On models with the igniter control a spark continues to operate for

15 seconds. If pilot ignition fails, there is a 5 minute wait and retry

or unit must be manually reset.

This control is non-adjustable and has no serviceable parts. The

removal of its cover voids the control warranty and may damage

the electronic circuit.

FIGURE 46