66

66

6

Where an exhaust fan is installed in the same room with a boiler,

sufficient openings for air must be provided in the walls.

UNDERSIZED OPENINGS WILL CAUSE AIR TO BE DRAWN INTO

THE ROOM THROUGH THE CHIMNEY, CAUSING POOR

COMBUSTION. SOOTING MAY RESULT WITH AN INCREASED

RISK OF ASPHYXIATION.

CHEMICAL VAPOR CORROSION

WARNING

CORROSION OF THE FLUEWAYS AND VENT SYSTEM MAY

OCCUR IF AIR FOR COMBUSTION CONTAINS CERTAIN

CHEMICAL VAPORS WHICH BREAK DOWN INTO ACIDS AT HIGH

TEMPERATURE. SUCH CORROSION MAY RESULT IN FAILURE

AND RISK OF ASPHYXIATION.

Water boiler corrosion and component failure can be caused by

the heating and breakdown of airborne chemical vapors. Spray

can propellants, cleaning solvents, refrigerator and air conditioning

refrigerants, swimming pool chemicals, calcium and sodium

chloride, waxes, and process chemicals are typical compounds

which are corrosive. These materials are corrosive at very low

concentration levels with little or no odor to reveal their presence.

Products of this sort must not be stored near the boiler. Also, air

which is brought in contact with the water boiler should not contain

any of these chemicals. If necessary, uncontaminated air should

be obtained from remote or outside sources.

INSTALLATION CLEARANCES

These boilers are approved for installation on combustible flooring

in an alcove with minimum clearance to combustibles of:

TABLE 4

HWB/HW HWB/HW HWB/HW HWB/HW HWB/HW

300 399 420 520 610 & 670

TOP 28" (711.2) 32" (812.8) 24" (609.6) 24" (609.6) 24" (609.6)

SIDES 6" (152.4) 6" (152.4) 24" (609.6) 24" (609.6) 24" (609.6)

REAR 6" (152.4) 6" (152.4) 24" (609.6) 24" (609.6) 24" (609.6)

VENT 6" (152.4) 6" (152.4) 6" (152.4) 6" (152.4) 6" (152.4)

Two inch (50.8mm) clearance is allowable from combustible

construction for hot water pipes.

Sufficient area should be provided at the front and rear of the unit

for proper servicing. Clearances of 24 inches (609.4mm) in the

rear and 48 inches (1,219mm) in the front are required by code. In

a utility room installation, the door shall be wide enough to allow

the boiler to enter or to permit the replacement of another appliance

such as a water heater.

LEVELLING

Each unit should be checked after installation to be certain that it is

level.

If the unit is not level, insert metal shims under the legs of the unit

to correct this condition.

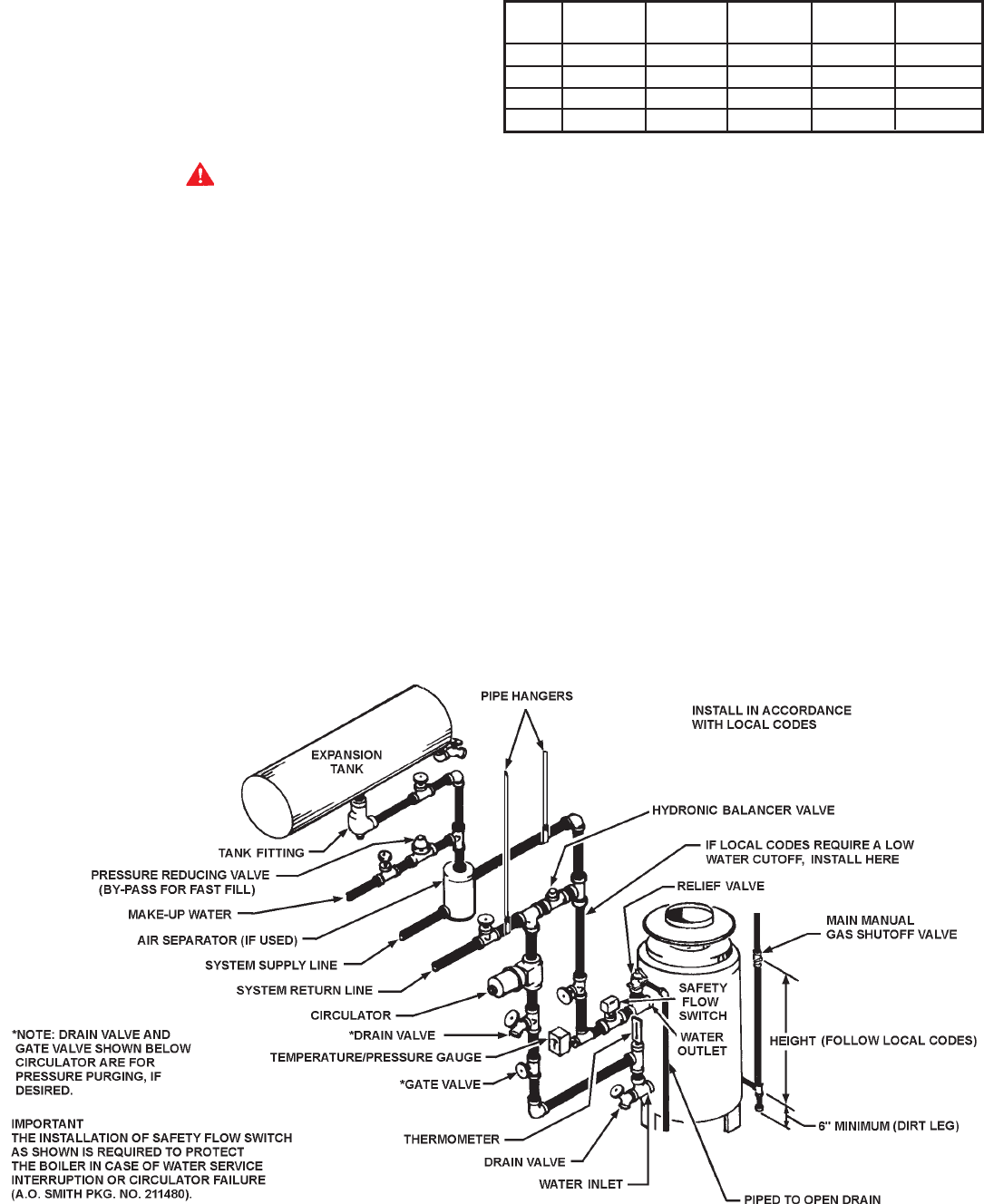

SYSTEM CONNECTIONS

The system installation must conform to these instructions and to

the requirements of the local code authority having jurisdiction.

Good practice requires that all heavy piping be supported.

A TYPICAL BOILER INSTALLATION

FIGURE 1