1111

1111

11

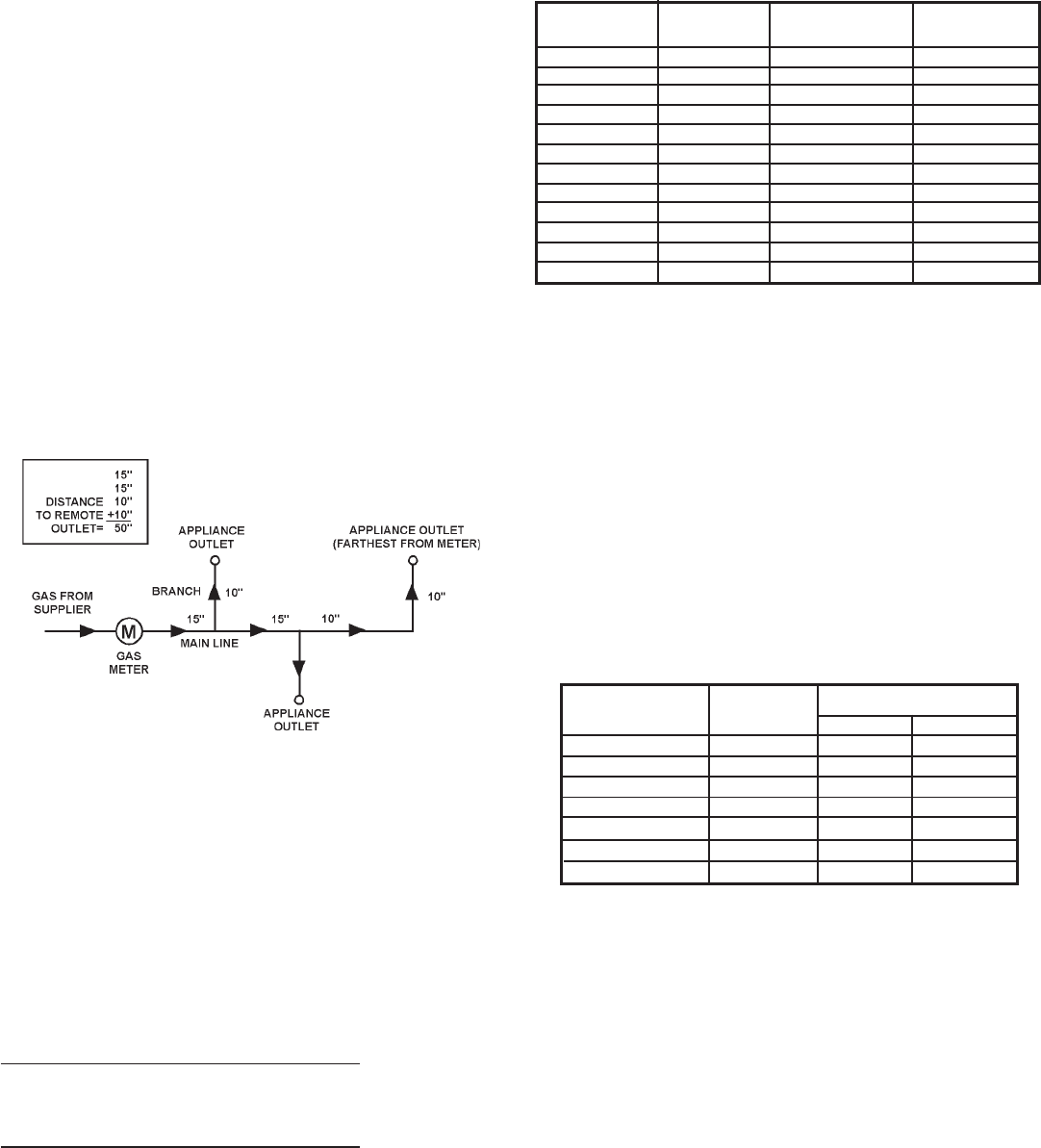

• In table 6, select the row showing the distance to the most

remote outlet or the next longer distance if the table does not

give the exact length. This is the only distance used in

determining the size of any section of gas piping. If the gravity

factor is to be applied, the values in the selected row of table 6

are multiplied by the appropriate multiplier from table 7.

• Total the gas demands of all appliances on the piping system.

Enter table 6, on the left hand side, at the row equal to or just

exceeding the distance to the most remote outlet. Select the

pipe size in the row with a capacity equal to or just exceeding

the total gas demand. This is the required main gas supply

line size leading away from the gas meter or regulator. To

determine the pipe size required for each branch outlet leading

away from the main supply line, determine the gas demand for

that outlet. Enter table 6 on the same row, and select the branch

pipe size for a capacity equal to or just exceeding the demand

at that outlet. The main line can be resized for a lesser capacity

after each branch outlet, since the gas demand is reduced.

Total the gas demands of all remaining appliances branching

off downstream on the main gas line. Re-enter table 6 in the

same row and select the appropriate pipe size with adequate

capacity. Repeat the branch sizing and main line re-sizing for

any remaining appliances in the system.

EXAMPLE

Job Condition:

Determining the required gas pipe size for a system composed of

two HWB/HW-420 boilers and two HWB/HW-610 boilers to be

installed as a multiple group, 50 lineal feet from meter. Gas to be

used has a .60 specific gravity and heating value of 1,000 Btu per

cubic foot.

Solution:

2 HWB/HW-420 Boilers = 840,000 Btuh

2 HWB/HW-610 Boilers = 1,220,000 Btuh

Total Btuh Input = 2,060,000 Btuh

Total Btuh Input = 2,060,000 Btuh = 2,060 cf/h

Btu per Cubic Foot of Gas 1,000

With a cubic foot per hour demand of 2,060 and with 50 lineal feet

of gas supply line, table 6 shows a pipe size of 3" (76mm) is

required.

NOTE: For other than .60 specific gravity, apply multiplier factor

as shown in table 7.

TABLE 7

MULTIPLIERS TO BE USED WITH TABLE 6 WHEN APPLYING

THE GRAVITY FACTOR TO OTHER THAN .60 SPECIFIC GRAVITY

Specific Specific

Gravity Multiplier Gravity Multiplier

.35 1.31 1.00 .78

.40 1.23 1.10 .74

.45 1.16 1.20 .71

.50 1.10 1.30 .68

.55 1.04 1.40 .66

*.60 (Nat.) 1.00 *1.50 (Prop.) .63

.65 .96 1.60 .61

.70 .93 1.70 .59

.75 .90 1.80 .58

.80 .87 1.90 .56

.85 .84 *2.00 (Butane) .55

.90 .82 2.10 .54

*Use these correction factors if exact specific gravity of the gas is not

known.

GAS PRESSURE REGULATORS

The gas pressure regulator is included in the combination gas

valve, fig. 6, and is set to operate on the gas specified on the boiler

model and rating plate.

Periodically check main burner, fig. 41, and pilot flame, fig. 42, for

proper operation. This should be checked every six months.

Do not subject the gas valve to inlet gas pressures of more than

14" W.C. (1/2 P.S.I.). If higher gas pressures are encountered, a

service regulator is necessary.

TABLE 8

CORRECT MANIFOLD PRESSURE FOR FULL

BOILER INPUT (IN INCHES OF WATER COLUMN)

Model Rated Manifold Pressure

Number Input Natural Propane

HWB/HW-300 300,000 3.5 10.0

HWB/HW-399 399,000 3.2 9.5

HWB/HW-420 420,000 3.5 10.0

HWB/HW-520 520,000 3.5 10.0

HWB/HW-610 610,000 3.5 10.0

HW-670 Nat. 660,000 3.5

HW-670 Prop. 670,000 10.0

Adjustment, if required, is performed as follows:

1. Set primary system temperature control dial (thermostat) at

lowest setting so that boiler will not call for heat.

2. Attach a pressure gauge to the tapping in the control string

elbow.

3. Reset primary system temperature control dial (thermostat)

to highest setting. Main burner will now ignite.

4. With main burner firing, adjust pressure, if necessary, by turning

pressure regulator adjusting screw with a screwdriver.

• Clockwise to increase pressure.

• Counterclockwise to decrease pressure.

5. Set primary system temperature control dial (thermostat) to

lowest setting.

6. Remove pressure gauge and replace sealing plug.