9

WARNING

FAILURE TO CORRECT BACK DRAFTS MAY CAUSE AIR

CONTAMINATION AND UNSAFE CONDITIONS.

Vent connectors serving appliances vented by natural draft shall

not be connected into any portion of mechanical draft systems

operating under positive pressure.

3. CONNECTING BOILER TO A COMMON VENT

Do not connect the boiler to a common vent or chimney with solid

fuel burning equipment. This practice is prohibited by most local

building codes as is the practice of venting gas fired equipment to

the duct work of ventilation systems.

Where a separate vent connection is not available and the vent

pipe from the boiler must be connected to a common vent with an

oil burning furnace, the vent pipe should enter the common vent or

chimney at a point ABOVE the flue pipe from the oil furnace.

UL/ULC listed doublewall type B-1 gas vents, through 24" (610

mm) diameter, can be installed in heated and unheated areas and

can pass through floors, ceilings, partitions, walls and roofs,

provided the required clearance is observed.

At the time of removal of an existing boiler, the following steps

shall be performed with each appliance remaining connected to

the common venting system. Perform these steps while the other

appliances remaining connected to the common venting system

are not in operation.

— Seal any unused openings in the common venting system.

— Visually inspect the venting system for proper size and

horizontal pitch and determine there is not blockage or

restriction, leakage, corrosion and other deficiencies which

could cause an unsafe condition.

— Insofar as is practical, close all building doors and windows

and all doors between the space in which the appliances

remaining connected to the common venting system are

located and other spaces of the building. Turn on clothes dryers

and any appliance not connected to the common venting

system. Turn on any exhaust fans, such as range hoods and

bathroom exhaust fans, so they will operate at maximum speed.

Close fireplace dampers.

— Place in operation the appliance being inspected. Follow the

lighting instructions. Adjust thermostat so appliance will

operate continuously.

— Test for spillage at the draft hood relief opening after five

minutes of main burner operation. Use the flame of a match

or candle, or smoke from a cigarette, cigar or pipe.

— After it has been determined that each appliance remaining

connected to the common venting system properly vents when

tested as outlined above, return doors, windows, exhaust fans,

fireplace dampers and any other gas burning appliance to their

previous conditions of use.

GAS CONNECTIONS

WARNING

THIS BOILER IS NOT INTENDED TO OPERATE AT GAS SUPPLY

PRESSURE OTHER THAN SHOWN ON THE RATING PLATE.

EXPOSURE TO HIGHER GAS SUPPLY PRESSURE MAY CAUSE

DAMAGE TO GAS VALVES WHICH CAN RESULT IN FIRE OR

EXPLOSION. IF OVERPRESSURE HAS OCCURRED SUCH AS

THROUGH IMPROPER TESTING OF GAS LINES OR

EMERGENCY MALFUNCTION OF THE SUPPLY SYSTEM, THE

GAS VALVES MUST BE CHECKED FOR SAFE OPERATION.

MAKE SURE THAT THE OUTSIDE VENTS ON THE SUPPLY

REGULATORS AND THE SAFETY VENT VALVES ARE

PROTECTED AGAINST BLOCKAGE. THESE ARE PARTS OF

THE GAS SUPPLY SYSTEM, NOT THE BOILER. VENT

BLOCKAGE MAY OCCUR DURING ICE BUILD-UP OR SNOW

STORMS.

WHEN LOCAL CODES REQUIRE A MAIN MANUAL SHUTOFF

VALVE OUTSIDE THE BOILER JACKET, A SUITABLE MAIN

MANUAL SHUTOFF VALVE MUST BE INSTALLED IN A

LOCATION COMPLYING WITH THOSE CODES.

IT IS IMPORTANT TO GUARD AGAINST GAS VALVE FOULING

FROM CONTAMINANTS IN THE GAS WAYS. SUCH FOULING

MAY CAUSE IMPROPER OPERATION, FIRE OR EXPLOSION.

IF COPPER SUPPLY LINES ARE USED THEY MUST BE

APPROVED FOR GAS SERVICE.

BEFORE ATTACHING THE GAS LINE BE SURE THAT ALL GAS

PIPE IS CLEAN ON THE INSIDE.

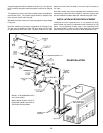

TO TRAP ANY DIRT OR FOREIGN MATERIAL IN THE GAS

SUPPLY LINE, A DIRT LEG (SOMETIMES CALLED DRIP LEG

OR SEDIMENT TRAP) UPSTREAM OF THE GAS CONTROLS,

MUST BE INCORPORATED IN THE PIPING. The dirt leg must be

readily accessible and not subject to freezing conditions. INSTALL

IN ACCORDANCE WITH RECOMMENDATIONS OF SERVING

GAS SUPPLIERS. REFER TO

NATIONAL FUEL GAS CODE, ANSI

Z223.1 AND/OR CAN/CSA-B149.1-00.

To prevent damage, care must be taken not to apply too much

torque when attaching gas supply pipe to gas valve gas inlet.

Fittings and unions in the gas line must be metal to metal type.

Apply joint compounds (pipe dope) sparingly and only to the male

threads of pipe joints. Do not apply compound to the first two

threads. Use compounds resistant to the action of liquefied

petroleum gases.

The boiler and its individual shutoff valve must be disconnected

from the gas supply piping system during any pressure testing of

that system at test pressures in excess of 1/2 psi (3.5 kPa).

The boiler must be isolated from the gas supply piping system by

closing its individual manual shutoff valve during any pressure

testing of the gas supply piping systems at test pressures equal to

or less than 1/2 psi (3.5 kPa).

The boiler and its gas connection must be leak tested before placing

the boiler in operation.

Provisions for vent, bleed and gas relief lines (when applicable).