5

FEATURES

IMPORTANT

Only qualified personnel shall perform the initial firing of the heater.

At this time the user should not hesitate to ask the individual any

questions regarding the operation and maintenance of the unit.

Lighting and Operating instructions are included at the rear of this

manual. By using this checklist the user may be able to make

minor operational adjustments and save unnecessary service calls.

However, the user should not attempt repairs which are not listed

under the USER column.

SAFETY RELIEF VALVES

Your local code authority may have other specific relief valve

requirements not covered below.

WARNING

THE PURPOSE OF A SAFETY RELIEF VALVE IS TO AVOID

EXCESSIVE PRESSURE WHICH MAY CAUSE TANK

EXPLOSION, SYSTEM OR BOILER DAMAGE.

TO AVOID WATER DAMAGE A DRAIN LINE MUST BE

CONNECTED TO A SAFETY RELIEF VALVE TO DIRECT

DISCHARGE TO A SAFE LOCATION. A DRAIN LINE MUST NOT

BE REDUCED FROM THE SIZE OF THE VALVE OUTLET AND IT

MUST NOT CONTAIN ANY VALVES BETWEEN THE BOILER AND

THE RELIEF VALVE OR THE RELIEF VALVE AND THE DRAIN

EXIT. IN ADDITION, THERE SHOULD NOT BE ANY

RESTRICTIONS IN A DRAIN LINE NOR SHOULD IT BE ROUTED

THROUGH AREAS WHERE FREEZING CONDITIONS MIGHT

OCCUR. DO NOT THREAD OR CAP THE DRAIN LINE EXIT.

RESTRICTING OR BLOCKING A DRAIN LINE WILL DEFEAT THE

PURPOSE OF THE RELIEF VALVE AND MAY CREATE AN

UNSAFE CONDITION. INSTALL A DRAIN LINE WITH A

DOWNWARD SLOPE SUCH THAT IT NATURALLY DRAINS

ITSELF.

If any safety relief valve is replaced, the replacement valve must

comply with the latest version of the ASME Boiler and Pressure

Vessel Code, Section IV (“HEATING BOILERS”). Select a relief

valve with a discharge rating NOT less than the boiler input, and a

set pressure NOT exceeding the working pressure of any component

in the system.

An ASME rated temperature and pressure relief valve must be

installed on each and every water storage tank in a hot water supply

system.

The storage tank temperature and pressure relief valve must comply

with the applicable construction provisions of the Standard for Relief

Valves and Automatic Gas Shutoff Devices for Hot Water Supply

Systems, ANSI Z21 or CAN/CSA-B149.1 (latest edition). The valve

must be of the automatic reset type and not embody a single-use

type fusible plug, cartridge or linkage.

ELECTRONIC INTERMITTENT PILOT

IGNITION CONTROL

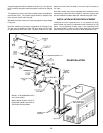

ALL MODELS - The solid state ignition control, fig. 2, ignites the

pilot burner gas by creating a spark at the pilot assembly. Pilot gas

is ignited and burns during each running cycle. The main burner

and pilot gases are cut off during the “OFF” cycle. Pilot gas ignition

is proven by the pilot sensor. Main burner ignition will not occur if

the pilot sensor does not first sense pilot ignition.

FIGURE 2

On natural gas models the igniter control continues to operate

(creating a spark) until the pilot burner is ignited or the ignition

system shuts down. Shut down occurs automatically if the pilot

burner does not ignite within 15 seconds. The unit then waits for

(5) minutes and retries ignition (standard models).

The electronic intermittent pilot ignition control and the 100% lockout

control are non-adjustable devices.

(See troubleshooting steps on page 40). If pilot is not lit and sensed

within the flame establishing timing for each module, the appliance

will shut down.

MANUAL RESET HIGH TEMPERATURE

SAFETY LIMIT CONTROL

This device senses water temperature in the boiler. When water

temperature exceeds dial setting, power to main gas valve is

interrupted and the boiler is shut down.

HOT WATER SUPPLY - Manual reset - factory set at 210°F (100°C).

Water temperature must drop at least 20°F (11°C) before reset is

possible.

HYDRONIC HEATING - Manual reset - factory set at 250°F (121°C).

Water temperature must drop at least 20°F (11°C) before reset is

possible.

Single stage and modulating units use a combined control as shown

in fig. 4.

Dual stage models are equipped with a limit like one shown in

figure 3.