27

HOT WATER SUPPLY APPLICATIONS

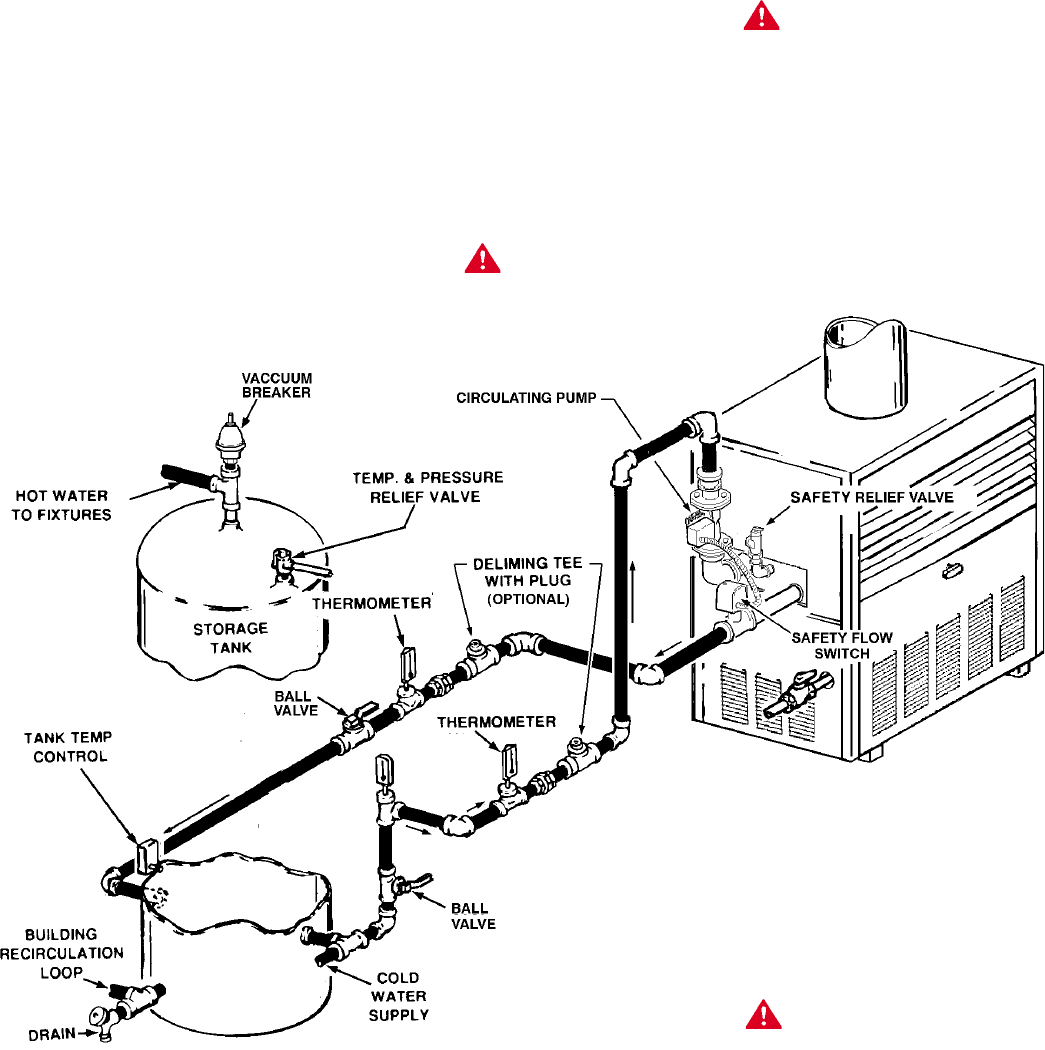

Cer-Temp 80 Recovery Systems

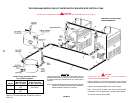

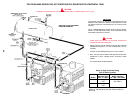

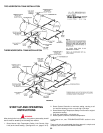

WATER LINE CONNECTIONS

This section provides detailed installation diagrams for typical

methods of application for the unit using a Cer-Temp 80 Recovery

System (for one temperature water).

This equipment must be protected against loss of water or loss of

water flow by the installation of a safety flow switch in the outlet

piping from the boiler. Piping and wiring diagrams show the

application of this accessory for this purpose.

These diagrams will serve to provide the installer with a reference

for the materials and methods of piping necessary for installation.

It is essential that all water and gas piping, vent connections,

electrical wiring, and check and flow regulating valves be installed

as shown on the diagrams.

Where excessive heat exchanger condensation exists due to

continued low water inlet temperatures, a bypass balance loop

must be installed (see page 15).

HARD WATER CONDITIONS

Where hard water conditions exist, water softening or the threshold

type of water treatment is recommended. This will protect the

dishwashers, coffee urns, water heaters, water piping and other

equipment. When water softening or water treatment is not

practical, a comparatively easy method of periodic lime removal

from the unit must be employed.

WARNING

Lime accumulation can reduce the life of the equipment, reduce

efficiency and waste fuel. Boiler failure due to lime or scale build-

up voids the warranty.

These units are so constructed that lime removal is simple and

complete, see PREVENTIVE MAINTENANCE.

ONE DURA-MAX (MODEL DW) COMMERCIAL BOILER WITH VERTICAL TANK

CAUTION

TO PREVENT CONDENSATION THE MINIMUM BOILER INLET TEMPERATURE IS 100°F (38°C)

IMPORTANT

SAFETY FLOW SWITCH AS SHOWN TO PROTECT THE BOILER IN CASE

OF WATER SERVICE INTERRUPTION OR CIRCULATOR FAILURE.

* SAFETY RELIEF VALVE RATING SHOULD NOT EXCEED PRESSURE

CAPACITY OF ANY COMPONENT IN THE SYSTEM.

CAUTION

PUMP MUST BE RATED FOR SYSTEM OPERATING TEMPERATURES

AND PRESSURE.

SEE TABLE 7 FOR GUIDE TO PIPE AND PUMP SIZING.

+ BALL VALVES ARE SHOWN FOR SERVICING BOILER, HOWEVER,

LOCAL CODES SHALL GOVERN THEIR USAGE.

INSTALL IN ACCORDANCE WITH ALL LOCAL CODES.

SEE PAGE 31 FOR

ADDITIONAL PIPING INFORMATION.