13

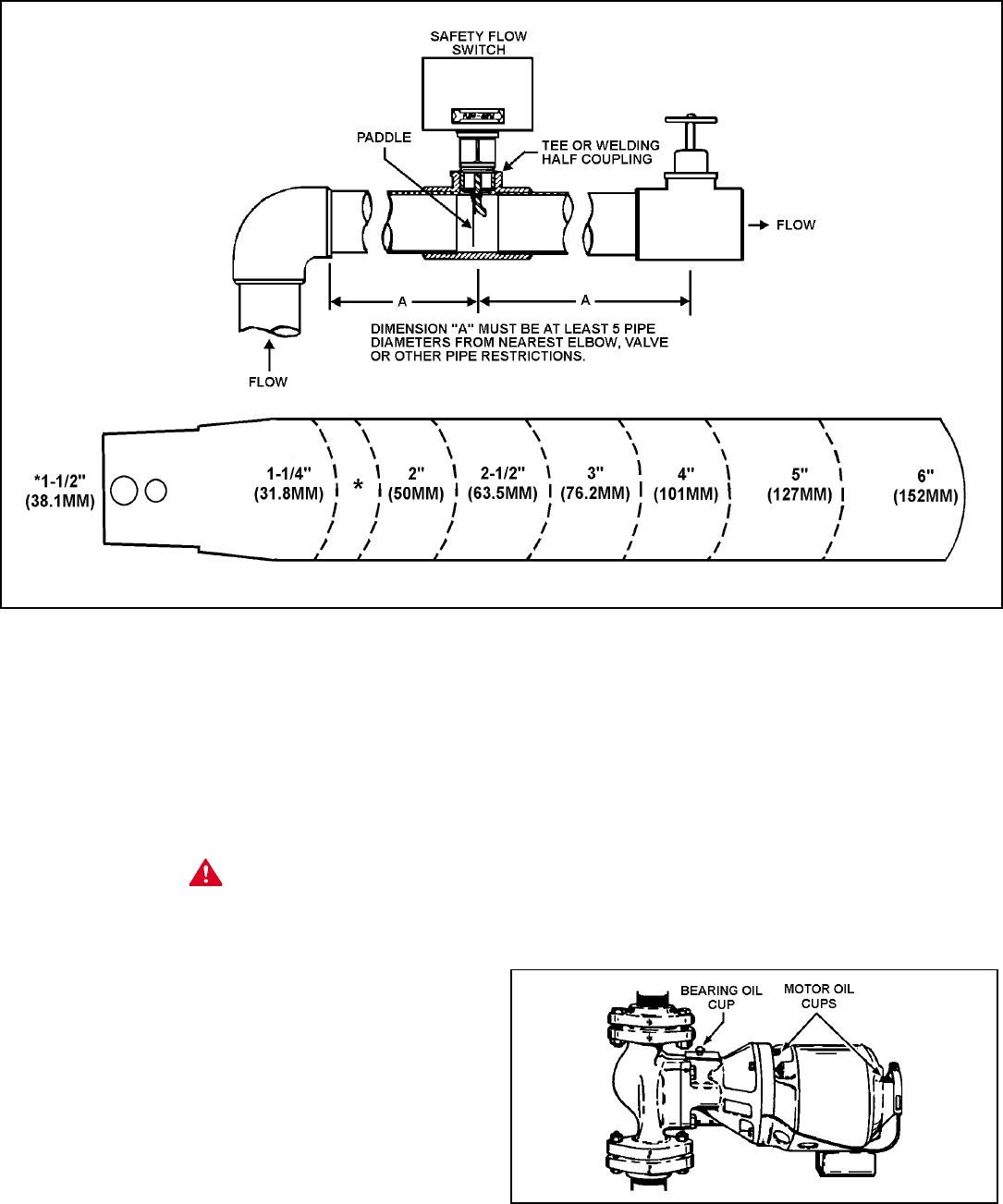

The flow switch shall be mounted in the top opening of the reducing

tee and provide adequate paddle length in the flow stream. For

example in a 2" pipe installation use a 2" x 2" x 1" reducing tee. For

2" or 3" pipe use the paddle segments as supplied. For other pipe

sizes (i.e. 2-1/2") trim the paddle to the proper pipe size, see fig. 8.

If a standard tee is used, install a face or hex bushing in the top

opening. The paddle must be adjusted or trimmed to the size of

the pipe in which it will be installed.

CAUTION

The paddle must not touch any part of the tee into which it is

installed. Screw the flow switch in position so the flat of the paddle

is at right angles to the flow. The arrow on the side case must

point in the direction of the flow.

To adjust the flow rate setting:

1. Remove the flow switch cover.

2. For higher flow rate—turn the range adjusting screw clockwise.

3. For lower flow rate—turn the range adjusting screw

counterclockwise.

Where units are installed in multiples, each boiler must be

individually protected by a safety flow switch.

CIRCULATING PUMP

Dura-Max boilers are designed to operate over a wide range of

temperatures and flow rates.

THE CIRCULATING PUMP MUST BE PROPERLY SIZED FOR

YOUR APPLICATION.

Water hardness, system pressure drop and temperature rise across

the boiler all affect how large a circulating pump must be.

Running "hard water" too slowly through the boiler can result in

damage due to lime or scale accumulation.

Running "soft water" too quickly through the boiler can result in

damage due to velocity flow erosion.

Table 4 has been designed to assist in determining operating ranges.

Use this chart as a guide when sizing pumps.

FIGURE 9

Although each circulator that requires oil is oiled and operated by

the manufacturer, IT MUST BE OILED AGAIN BEFORE BEING

OPERATED. Oil the three oil cups (2 on the motor, 1 on the pump)

as instructed on the oil tube supplied with the unit, fig. 9.

FIGURE 8