29

5. Install rain cap and small diameter pipe assembly in Y concentric

tting and large pipe assembly. Ensure small diameter pipe is

bottomed and cemented in Y concentric tting.

6. Secure assembly to structure as shown in Figure 24 using eld-

supplied metal strapping or equivalent support material.

NOTE: Ensure termination location clearance dimensions are

as shown in the diagrams found in Figure 24 and 25. When

extending the length of the 4” pipe, the added length beyond

21-1/8” must be deducted from the maximum equivalent feet

of vent pipe.

NOTE: If assembly needs to be extended to allow side wall

thickness requirement, the 2 pipes supplied in the kit may be

replaced by using same diameter, eld-supplied SDR-26 PVC

(D2241) pipe. Do not extend 21 1/8” dimension more than 60 in.

(See Figure 20.)

Do not use eld-supplied couplings to extend pipes. Airow

restriction will occur and the heater pressure switch may cause

intermittent operation.

7. Cement heater combustion-air and vent pipes to concentric vent

termination assembly. See Figure 25 for proper pipe attachment.

8. Operate heater through 1 heat cycle to ensure combustion-air and

vent pipes are properly connected to concentric vent termination

connections.

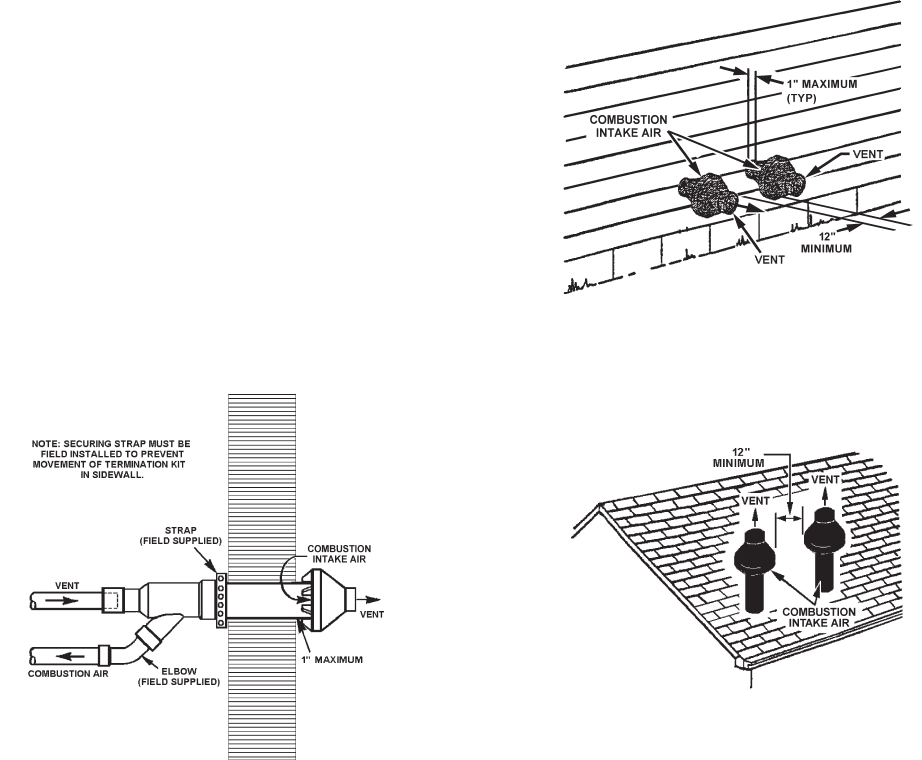

FIGURE 25.

MULTI-CONCENTRIC VENT TERMINATIONS

When two or more appliances are direct vented with concentric

vent terminations near each other, each appliance must be

individually vented. NEVER common vent this appliance. When

two or more appliances are direct vented using concentric vent

terminations, the appliances may be vented as shown in Figure

26 and 27.

FIGURE 26.

Concentric Vent Terminations

for Horizontal Direct Venting.

FIGURE 27.

Concentric Vent Terminations for Vertical

Direct Venting through a roof.