16

SECTION F

Polishing Process for Single-mode Connector Return

Loss >40dB

This process will need to be used for single-mode finishes with a

reflection requirement of 40dB or better. This specification is outlined in

Bellcore TR-NWT-00326 Issue 3.

1. PREPARE THE POLISHING SURFACE

Clean the surface of the soft polishing pad with a lint-free cloth

moistened with isopropyl alcohol. Blow clean both sides of a

sheet of brown 5 ϑm lapping acetate. Place the acetate shiny

side down onto the soft pad.

Note: Carefully follow safety, health and disposal information on

container label or Material Safety Data Sheet for isopropyl

alcohol being used.

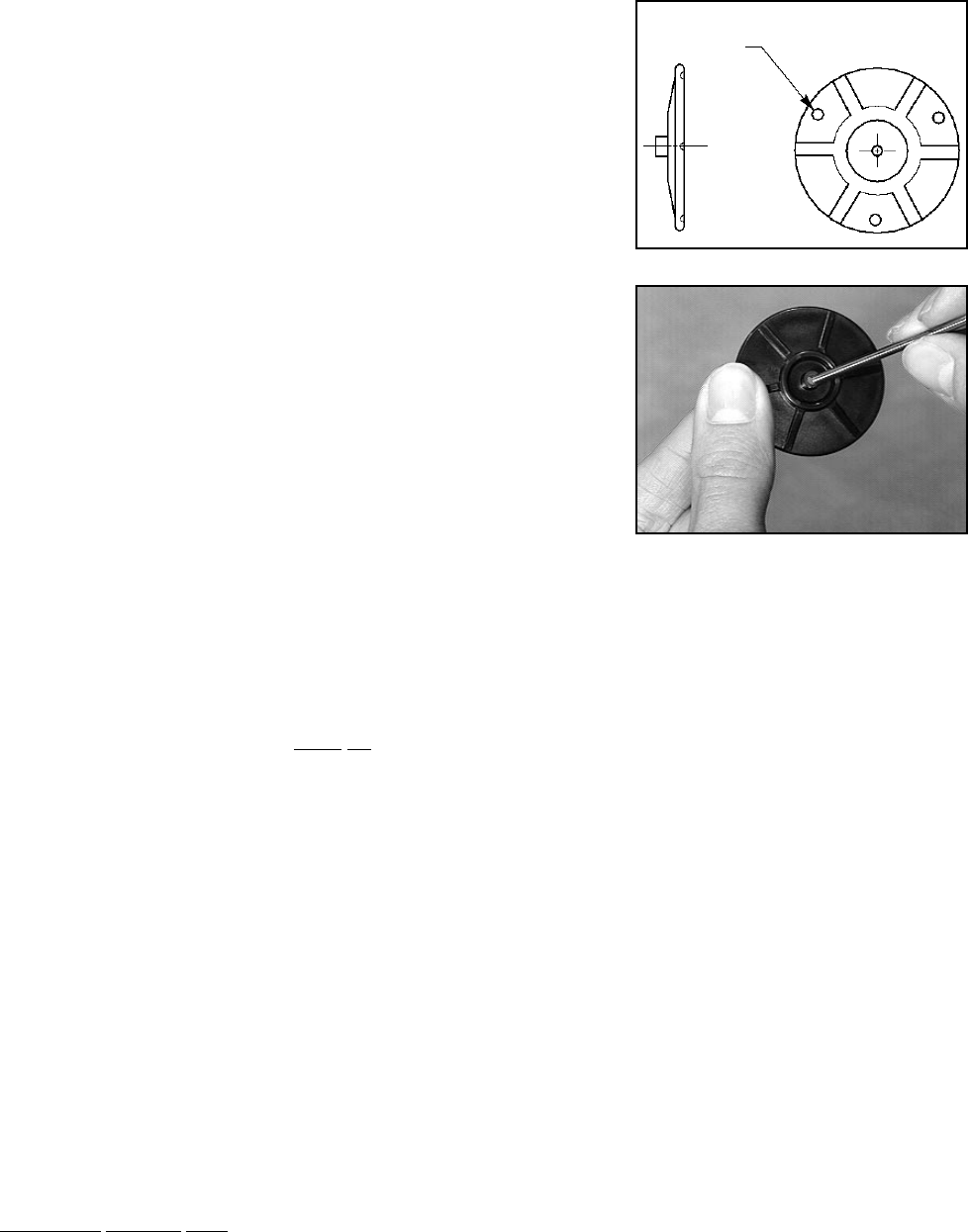

Fig. F1

Fig. F2

2. PREPARE THE POLISHING JIG

Wipe the polishing surface of the composite jig with a lint-free

cloth moistened with isopropyl alcohol. Blow the entire jig clean

with compressed air.

Note: The polishing jig used in these procedures is designed

with three "wear indicators" on its polishing surface (Fig.

F1). Each indicator is 0.002" deep. As polishing is done,

the surface of the jig will be worn away. Uniform pressure

across the jig's surface during polishing will result in the

areas surrounding the "indicators" to wear.

Note: The composite polishing jig must be used when following

the >40dB process. The stainless steel jig, which is

available separately, can be used with the standard

polishing process only.

3. CHECK THE FERRULE HOLE IN THE POLISHING TOOL

In order to achieve greater than -40dB reflection on single-mode

connectors, it is extremely important that the polishing tool

accurately holds the ceramic ferrule radius on center during the

polishing procedure. This is accomplished by the squareness and

tight dimensional clearance of the polishing jig.

Periodically, check the ferrule hole in the jig using the NO/GO

gauge pin provided in the Field Termination Kit. The NO/GO pin

should not even start into the hole if the polishing jig is within

tolerance. To check the ferrule hole, gently insert the gauge pin

through the hole on the top of the polishing tool (Fig. F2). DO

NOT TRY TO FORCE THE PIN THROUGH THE OPENING. If

the pin does not pass through the hole, continue to use the tool to

polish single-mode connectors. If the pin does pass through the

opening of the tool, the tool has worn and should be used for

multimode finishes only.

Wear Indicator

(3 Places)