14

SECTION E

Standard Polishing Process for Single-mode and

Multimode Connectors

3. PERFORM THE 5 ϑm FINISH

While holding the polishing jig in your hand, insert the connector

so that the ferrule end does not protrude past the bottom of the

polishing jig. This is to ensure that the extended fiber from the

ferrule will not be broken off below the epoxy level upon initial

contact with the lapping film.

Note: The ferrule must be inserted straight into the jig hole. If

the ferrule tip is wiggled upon entering the composite jig,

the composite jig may be damaged.

Note: If the connector does not fit easily into the jig, examine the

sides of the ceramic ferrule for epoxy. Any excess epoxy

can be removed with a razor blade.

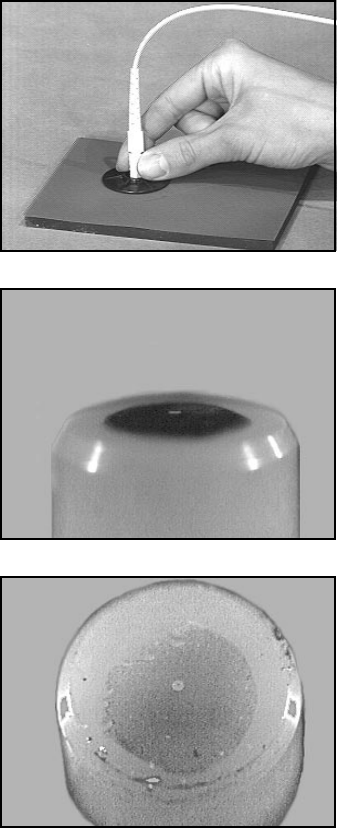

While holding both the connector and the polishing jig in one

hand, slowly place the jig on the lapping film and begin to polish in

a figure 8 motion without applying pressure on the connector (Fig.

E2). Light scratch marks should begin to appear on the acetate

surface.

Continue to polish until the fiber is flush with the epoxy bead

(approximately 6 figure 8's) (Fig. E3). Once the fiber is supported

by the epoxy bead, begin applying light pressure on the connector

while polishing in a figure 8 motion. Continue to polish on the 5

ϑm acetate until a thin layer of light blue color epoxy remains on

the ceramic tip (Fig. E4). Stop when the outer edges of the epoxy

layer start to break up and feather. This can be seen using the 7X

jewelers loupe.

Note: Until familiar with the process from this point, inspect the

remaining epoxy after each single figure 8 until a thin

feathered edge remains. DO NOT REMOVE ALL EPOXY

WITH THE 5

ϑ

m ACETATE.

Note: The 5

ϑ

m lapping acetate can be cleaned with isopropyl

alcohol and blown dry for reuse. The sheet can be used to

polish 2 to 4 connectors.

Fig. E2

Fig. E3

Fig. E4