13

SECTION E

Standard Polishing Process for Single-mode and

Multimode Connectors (>30dB)

Note: See Section F to achieve >40 dB Return Loss.

1. PREPARE THE 5 ϑm POLISHING SURFACE

Clean the surface of the soft polishing pad with a lint-free cloth

dampened with isopropyl alcohol. Blow clean both sides of a

sheet of brown 5 ϑm lapping acetate. Place the acetate shiny

side down onto the soft pad.

Note: Carefully follow safety, health and disposal information on

container label or Material Safety Data Sheet for isopropyl

alcohol being used.

2. PREPARE THE POLISHING JIG AND CONNECTOR

Wipe the polishing surface of the jig with a lint-free cloth

moistened with isopropyl alcohol. Blow the entire jig clean with

compressed air. Clean the connector with compressed air only,

since wiping it may break the fiber.

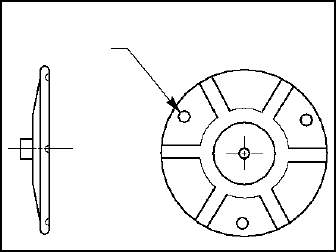

Note: The polishing jig used in these procedures is designed

with three "wear indicators" on its polishing surface (Fig.

E1). Each indicator is 0.002" deep. As polishing is done,

the surface of the jig will be worn away. Uniform pressure

across the jig's surface during polishing will result in the

areas surrounding the "indicators" to wear evenly. Non-

uniform pressure will result in one or two indicators

disappearing, thereby requiring the jig to be replaced.

Fig. E1

Wear Indicator

(3 Places)