279550-YIM-A-0207

Unitary Products Group 17

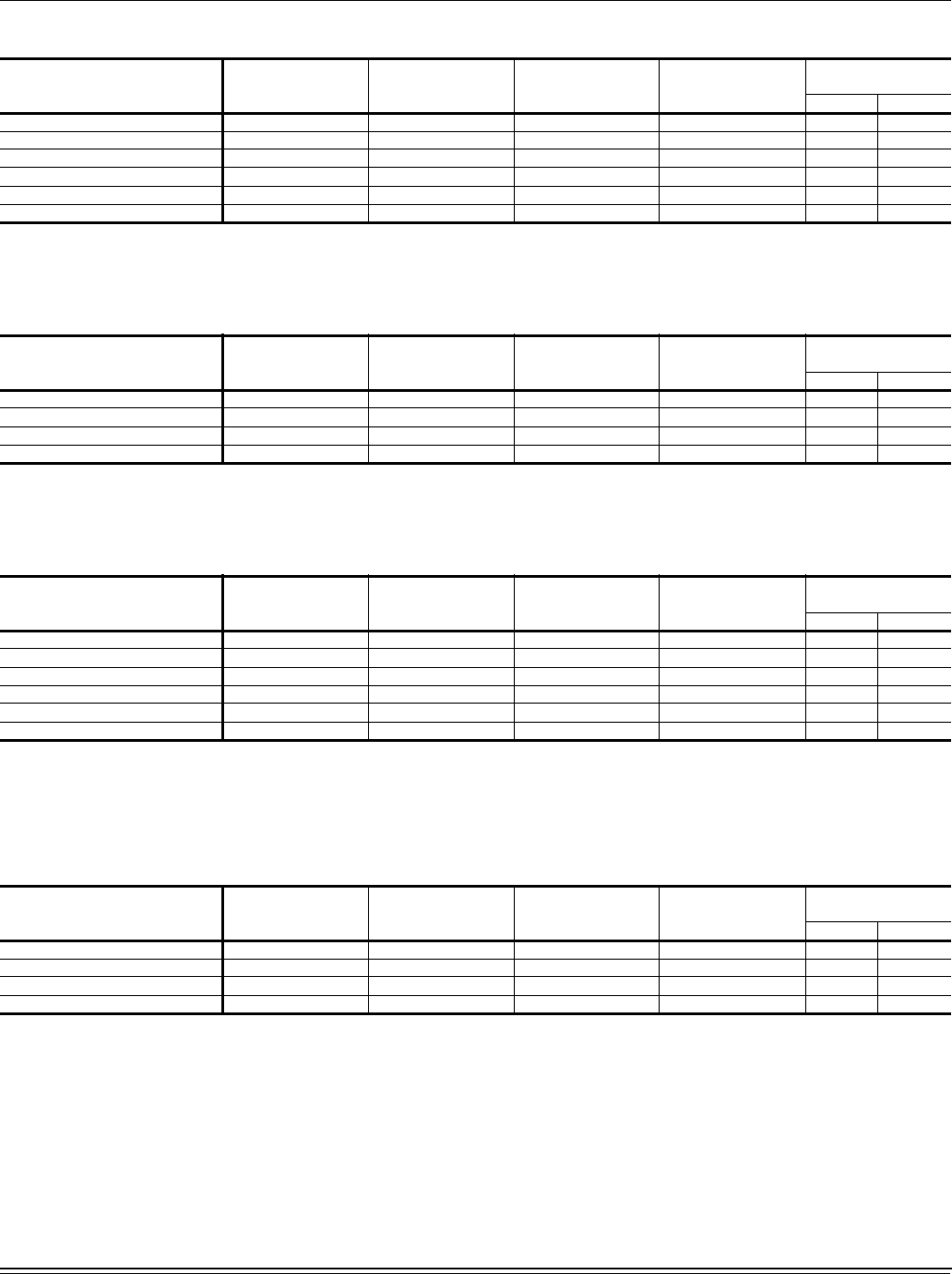

Table 9: Natural Gas Application Data-Single Stage

Available On Models

Input

(MBH)

1

1. Heating capacity valid for elevations up to 2000 feet above sea level. For elevations above 2,000 feet, rated capacity should be reduced by

4% for each 1,000 feet above sea level.

Output

(MBH)

Gas Rate

2

Ft.

3

/Hr.

2. Based on 1075 BTU/Ft.

3

.

Number of

Burners

Temp. Rise ºF

At Full Input

3

3. The air flow must be adequate to obtain a temperature rise within the range shown. Continuous return air temperature should not be below 55°F.

Min. Max.

2 Ton 45 36 42 2 25 55

2 Ton 70 56 65 3 30 60

3,4 Ton 80 64 74 3 25 55

3 Ton 108 87 100 4 45 75

4 Ton 108 87 100 4 35 65

4 Ton 135 108 126 5 45 75

Table 10: Natural Gas Application Data-Two Stage

Available On Models

Input

(MBH)

1

High Fire/Low Fire

1. Heating capacity valid for elevations up to 2000 feet above sea level. For elevations above 2,000 feet, rated capacity should be reduced by

4% for each 1,000 feet above sea level.

Output

(MBH)

High Fire/Low Fire

Gas Rate

2

Ft.

3

/Hr.

High Fire/Low Fire

2. Based on 1075 BTU/Ft.

3

.

Number of

Burners

Temp. Rise ºF

At Full Input

3

3. The air flow must be adequate to obtain a temperature rise within the range shown. Continuous return air temperature should not be below 55°F.

Min. Max.

2 Ton 70 / 45.5 56 / 36.4 65 / 42 3 30 60

3 Ton 108 / 70.2 87 / 56.2 100 / 65 4 45 75

4 Ton 108 / 70.2 87 / 56.2 100 / 65 4 35 65

4 Ton 135 / 87.75 108 / 70.2 126 / 82 5 45 75

Table 11: Propane

1

(LP) Gas Application Data-Single Stage

1. Propane applications are accomplished by field installation of a Propane Conversion Accessory, Model 1NP0807 for 2 Ton unit with 33-1/2”

tall cabinet and Model 1NP0808 for 3 and 4 Ton units with 41-1/2” tall cabinets.

Available On Models

Input Capacity

(Mbh)

2

2. Heating capacity valid for elevations up to 2,000 feet above sea level. For elevations above 2,000 feet, rated capacity should be reduced

by 4% for each 1,000 feet above sea level.

Output Capacity

(Mbh)

Gas Rate

3

Ft.

3

/Hr.

3. Based on 2500 BTU/Ft.

3

.

Number of Burners

Temp. Rise ºF

At Full Input

4

4. The air flow must be adequate to obtain a temperature rise within the range shown. Continuous return air temperature should not be below 55°F.

Min. Max.

2 Ton 45 36 18 2 25 55

2 Ton 70 56 28 3 30 60

3,4 Ton 80 64 32 3 25 55

3 Ton 108 87 43 4 45 75

4 Ton 108 87 43 4 35 65

4 Ton 135 108 54 5 45 75

Table 12: Propane

1

(LP) Gas Application Data-Two Stage

1. Propane applications are accomplished by field installation of a Propane Conversion Accessory, Model 1NP0809 for 2 Ton unit with 33-1/2”

tall cabinet and Model 1NP0810 for 3 and 4 Ton units with 41-1/2” tall cabinets.

Available On Models

Input Capacity

(Mbh)

2

High Fire/Low Fire

2. Heating capacity valid for elevations up to 2,000 feet above sea level. For elevations above 2,000 feet, rated capacity should be reduced

by 4% for each 1,000 feet above sea level.

Output Capacity

(Mbh)

High Fire/Low Fire

Gas Rate

3

Ft.

3

/Hr.

High Fire/Low Fire

3. Based on 2500 BTU/Ft.

3

.

Number of Burners

Temp. Rise ºF

At Full Input

4

4. The air flow must be adequate to obtain a temperature rise within the range shown. Continuous return air temperature should not be below 55°F.

Min. Max.

2 Ton 70 / 45.5 56 / 36.4 28 / 18.2 3 30 60

3 Ton 108 / 70.2 87 / 56.2 43 / 27.95 4 45 75

4 Ton 108 / 70.2 87 / 56.2 43 / 27.95 4 35 65

4 Ton 135 / 87.75 108 / 70.2 54 / 35.1 5 45 75