JOHNSON CONTROLS

10

FORM 100.50-EG5 (108)

Application Data (continued)

VAV SUPPLY AIR PRESSURE CONTROL

Traditional packaged rooftop systems use inlet guide

vanes (IGVs) for duct static pressure control. These

control supply duct pressure by modulating dampers

(introducing losses and ineffi ciencies) on the inlet of the

fan, open and closed. YORK’s variable frequency drives

(VFDs) offer superior fan speed control and quieter,

energy effi cient operation.

For VAV applications, the YORK Eco

2

unit uses a VFD

to modulate fan speed and maintain a constant duct

static pressure. VFDs offer superior control over the

operation of the unit at part load, and offer the additional

benefi ts of quieter and more effi cient operation when

compared to IGV.

HARSH ENVIRONMENTS – CONDENSER AND

EVAPORATOR COIL PROTECTION

For harsh environmental conditions such as seashore

applications, YORK offers three types of coil protection:

copper fi n material, black fi n and Technicoat coatings.

YORK recommends that for corrosive environments that

copper fi ns be used to protect the evaporator and/or

condenser coils. In areas where chemicals that can

corrode copper are present, such as ammonia, YORK

recommends that the black fi n or Technicoat coating be

used for maximum protection.

• Copper-Fin Evaporator and Condenser Coil

– Copper fi ns can be used instead of aluminum for

additional corrosion protection. However, it is not

suitable for areas that are subject to acid rain or

exposed to ammonia.

• Pre-Coated Condenser Fins – Black fi n coating

(yellow fi n for evaporator fi ns) is pre-coated appli-

cation epoxy on aluminum fi n stock to guard from

corrosive agents and insulate against galvanic

potential. It is used for mild seashore or industrial

locations. This can provide corrosion resistance

comparable to copper fi n coils in typical seashore

locations.

• Post-Coated Condenser Fins – Technicoat (a

post-coated application of epoxy) can be used for

seashore and other corrosive applications with the

exception of strong alkaloides, oxidizers, wet bro-

mide, chlorine and fl uorine in concentrations greater

than 100 ppm. Any of the above suitable options

should be selected based on the particular project

design parameters and related environmental fac-

tors. The application should be further reviewed and

approved by the consulting engineer or owner based

on their knowledge of the job site conditions.

BUILDING PRESSURE CONTROL SYSTEMS

Building pressure control systems are often neces-

sary when economizers are used to bring in outdoor

air. Without proper building exhaust, the building may

become over pressurized. The pressure control system

maintains the proper building pressure by expelling the

appropriate amount of air from the building.

Exhaust/relief fans – In this application, a powered

exhaust fan may be suitable, however careful consid-

eration of the fan type is necessary. YORK offers a

centrifugal powered exhaust fan to perform this function.

Some manufacturers use a propeller exhaust fan, which

cannot handle the static pressure requirements.

For systems with moderate to low return static pressure,

an exhaust fan is recommended. The benefi t of the ex-

haust fan is that it does not run all of the time, and may

facilitate compliance with the ASHRAE 90.1 fan motor

horsepower requirement.

The exhaust fan operates in parallel with the supply

fan. In this arrangement, the supply fan handles the full

static pressure requirements of the system. For normal

building pressure control, the exhaust fan operates to

draw air from the return plenum and exhaust it out of

the building.

The exhaust fan confi guration is available in two forms,

modulating and non-modulating. Modulating is the most

common and recommended for the majority of applica-

tions, while non-modulating should be used with in only

certain circumstances.

In the modulating exhaust system, the volume of airfl ow

exhausted from the building is proportional to the enter-

ing volume of outside air. Control is accomplished via

either a discharge damper or a variable-frequencydrive

(VFD). YORK recommends the use of a VFD to reduce

energy consumption, sound levels and improved reli-

ability due to fewer moving parts.

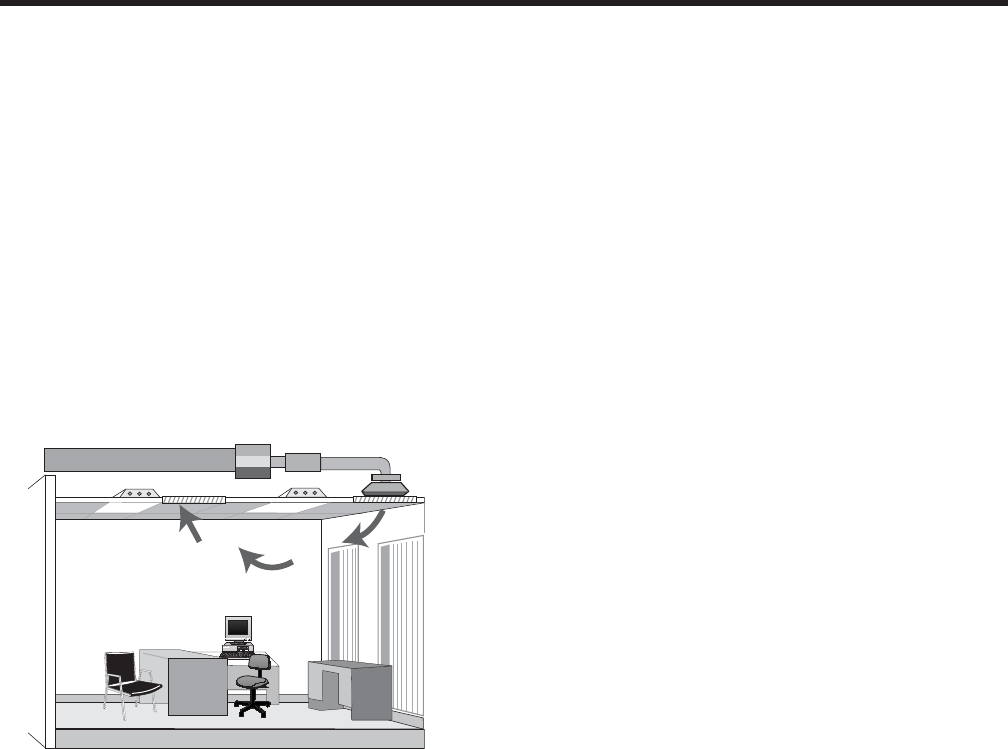

FIG. 1. TRADITIONAL OVERHEAD VAV AIR

DELIVERY SYSTEM