27

ZIP52 FINISHING - PF .

OPERATING MANUAL

EDITION 01 /2010 PART NO. ZZB012ENG

5.3 WORK

5.3.1 SPRAYING

for 2301832, 2301836, 2301837

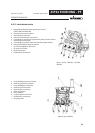

Make sure that the pressure regulator knob (H) is turned fully anti-

clockwise (0 bar pressure).

Open the air cutoff valve (I) and turn the motor air pressure regulator knob

(H) clockwise until the pump starts.

(Set the air pressure on the gauge (D) to 2 bar).

Open the re-cycle valve (L).

Lift the suction pipe and wait until the pump is completely empty from

the solvent previously pumped for the fi rst washing.

NOTE: The solvent used for the fi rst washing may contain testing fl uid resi-

dues, therefore avoid using it to dilute the paint.

Insert the suction pipe (M) into the paint container.

Wait until the pump is full. Close the re-cycle valve (L). If the product re-

quires a continuous agitation, adjust the re-cycle valve opening so as to

obtain the desired delivery.

Set the motor air pressure (H) on the gauge (D) to 5-5,5 bar or even more,

if the paint viscosity requires it.

Open the gun (T) and drain the solvent contained inside the hose. Close

the gun (T) as soon as paint starts coming out. The pump stops while it is

still pressurized.

Set the paint pressure using the regulator (G) until obtaining a pressure of

1-1,5 bar on manometer (E).

Adjust the atomising air pressure using the regulator (B) and make sure

the pressure on manometer (F) is 1,5-2 bar. You can now start painting.

for 2301838

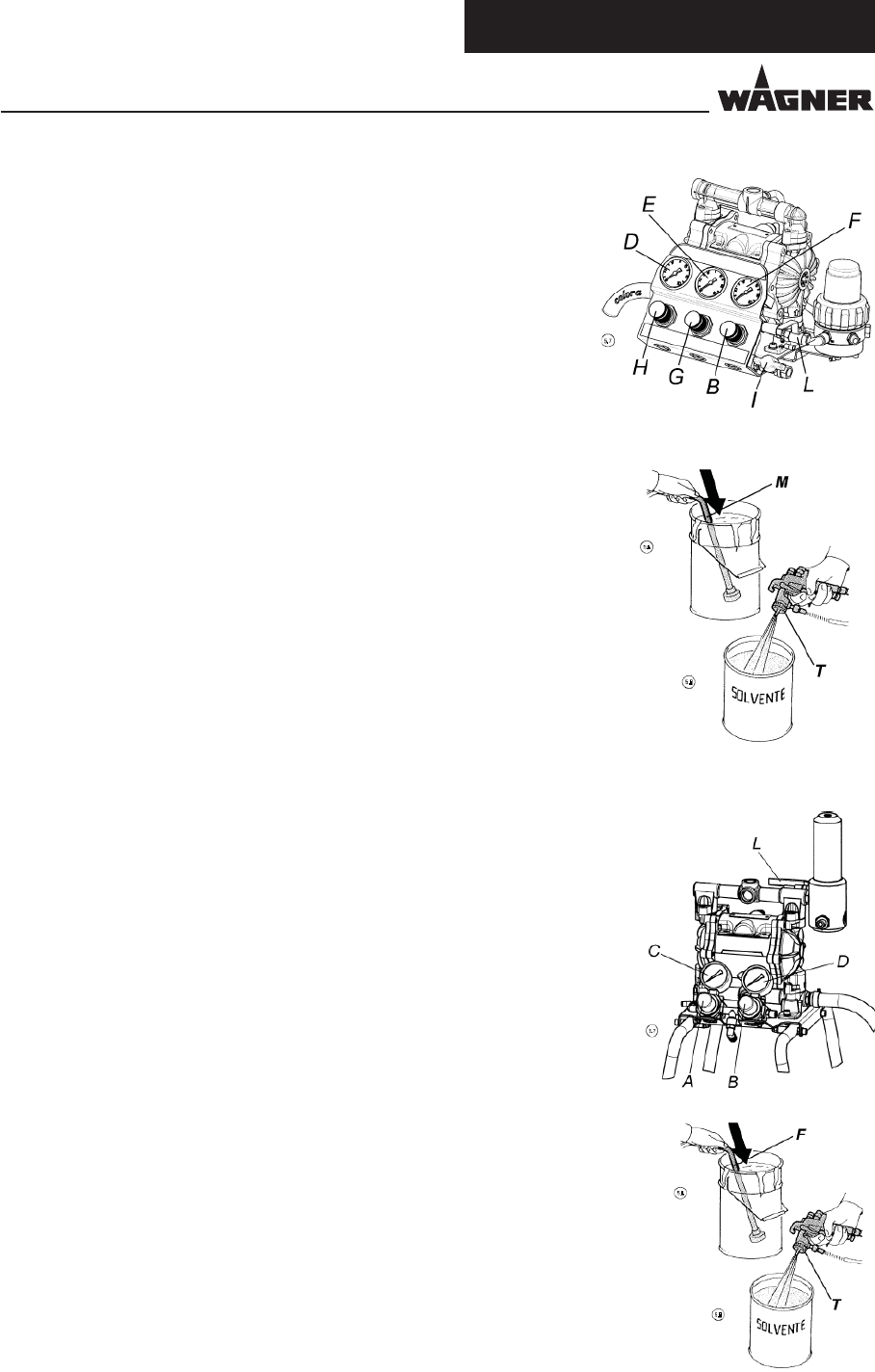

Make sure that the pressure regulator knob (A) is turned fully anti-

clockwise (0 bar pressure).

Open the air cutoff valve and turn the motor air pressure regulator knob

(A) clockwise until the pump starts. (Set the air pressure on the gauge (C)

to 2 bar).

Open the re-cycle valve (L).

Lift the suction pipe and wait until the pump is completely empty from

the solvent previously pumped for the fi rst washing.

NOTE: The solvent used for the fi rst washing may contain oil residues, the-

refore avoid using it to dilute the paint.

Insert the suction pipe (F) into the paint container.

Wait until the pump is full. Close the re-cycle valve (L). If the product re-

quires a continuous agitation, adjust the re-cycle valve opening so as to

obtain the desired delivery.

Set the motor air pressure (A) on the gauge (C) to 3-5 bar or even more, if

the paint viscosity requires it.

Open the gun (T) and drain the solvent contained inside the hose. Close

the gun (T) as soon as paint starts coming out. The pump stops while it is

still pressurized.

Adjust the atomising air pressure using the regulator (B) and make sure

the pressure on manometer (D) is 1,5- 2 bar.

You can now start painting.