26

ZIP52 FINISHING - PF .

M

OPERATING MANUAL

EDITION 01 /2010 PART NO. ZZB012ENG

2301838

5.2.3 WASHING

5.2.4 UNIT PRESSURE TIGHTNESS TEST

2301832, 2301836,

2301837

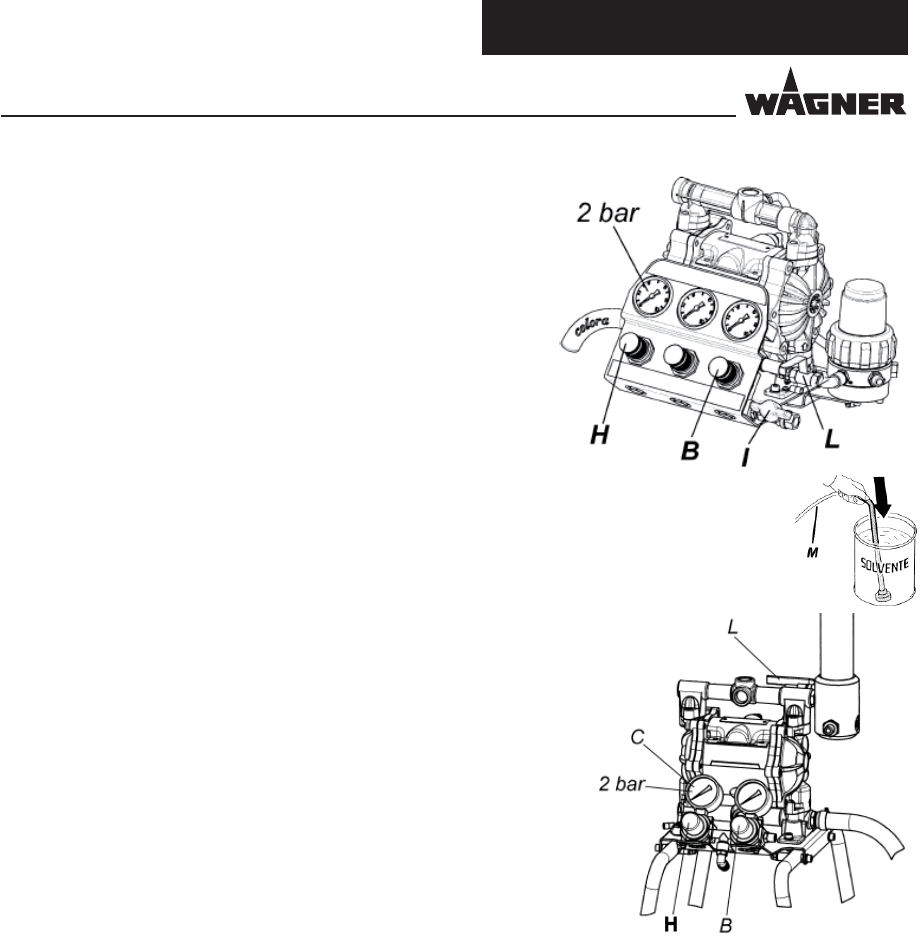

The pump has been tested using mineral oil. Before using it, it

is best to let it wash once using an adequate solvent. To do this,

place the metallic side of the suction pipe (M) inside a container

full of solvent.

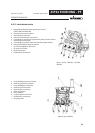

Open the re-cycle valve (L).

Make sure that the pressure regulator knob (H) is turned fully

anti-clockwise (0 bar pressure). Open the air cutoff valve (I) (on

the c

ompressed air line for 2301838) and turn the motor air pres-

sur

e regulator (H) knob clockwise until the pump starts. It is best

to keep the atomization air valve (B) closed during washing ope-

rations.

Set the motor air pressure to 2 bar.

The pump sucks solvent and pours it back into the container

through the re-cycle system, thus cleaning itself.

Let the solvent fl ow inside the pump for 2 or 3 minutes.

NOTE: In case the pump does not start, check that the gauge (C)

reads at least 2 bar, close the delivery air on-off valve, discharge

the residual pressure by turning the knob of the relative regula-

tor anticlockwise, and then reset the pressure using the regulator

and instantly reopen the air on-off valve. If necessary, repeat the

operation several times.

Keeping the gun on the solvent container, pull the trigger and let the solvent re-cycle

for some minutes through the gun delivery pipe. If the solvent fl ow coming out from the

gun is poor, use the recycling valve lever (L) to obtain a higher pressure from the gun. At

this point, all components have been through the fi rst washing, the equipment has no

unwanted fl uid inside and is ready for painting; lift the suction pipe from the dirty solvent

container and empty the pump completely.

Plunge the suction pipe and refi ll the pump with clean solvent, the turn off the air using the

motor air pressure regulator (H).

NOTE: In case you are pumping liquids, such as catalyzed resins, which are bound to harden

up, once: you have fi nished using the pump you must wash it, as well as anything that may

be connected to it, in a thorough way, using a solvent suitable for the type of resin being

used. You must then leave the pump full of solvent until it is next used.

Close the gun, close the re-cycle valve (L), gradually increase the motor feeding air pressu-

re (H) and the reducer controlling air (G) until reaching the max. acceptable value for the

pump and connected equipment, make sure there are no leaks from fi ttings or pipe as well

as from pump and antipulsation tank reducer fi lter.