25

ZIP52 FINISHING - PF .

OPERATING MANUAL

EDITION 01 /2010 PART NO. ZZB012ENG

5.2.2 EMERGENCY STOPPING

Before every start-up, the following points should be observed as laid down in the operating

manual:

- If installed secure gun with safety catch

- Check the permissible pressures

- Check all connections for leaks

- Check hose for damage

It should be ensured that the unit is in the following state before carrying out any work on it:

- The pressure should be released from the pump and high-pressure hose with gun (if

installed).

- The gun should be secured with safety catch (if installed).

- The air supply should be interrupted

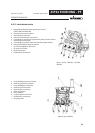

Emergency stopping for 2301832, 2301836,

2301837

To stop the equipment in good time, close the air on-off valve

(I) or release pressure through the regulator knob (H) thus stop-

ping the feeding air to the motor.

Carry out the pump priming operations correctly to prevent

pressurized air babbles from being trapped.

Pneumatic pumps can keep all components connected to the

delivery under pressure, even when the driving air feed is clo-

sed. To prevent harm to people, as well as to avoid damaging

things or the environment, after stopping the pump it is best

to release the pressure by keeping the delivery valve open or

opening the recycling valve (L).

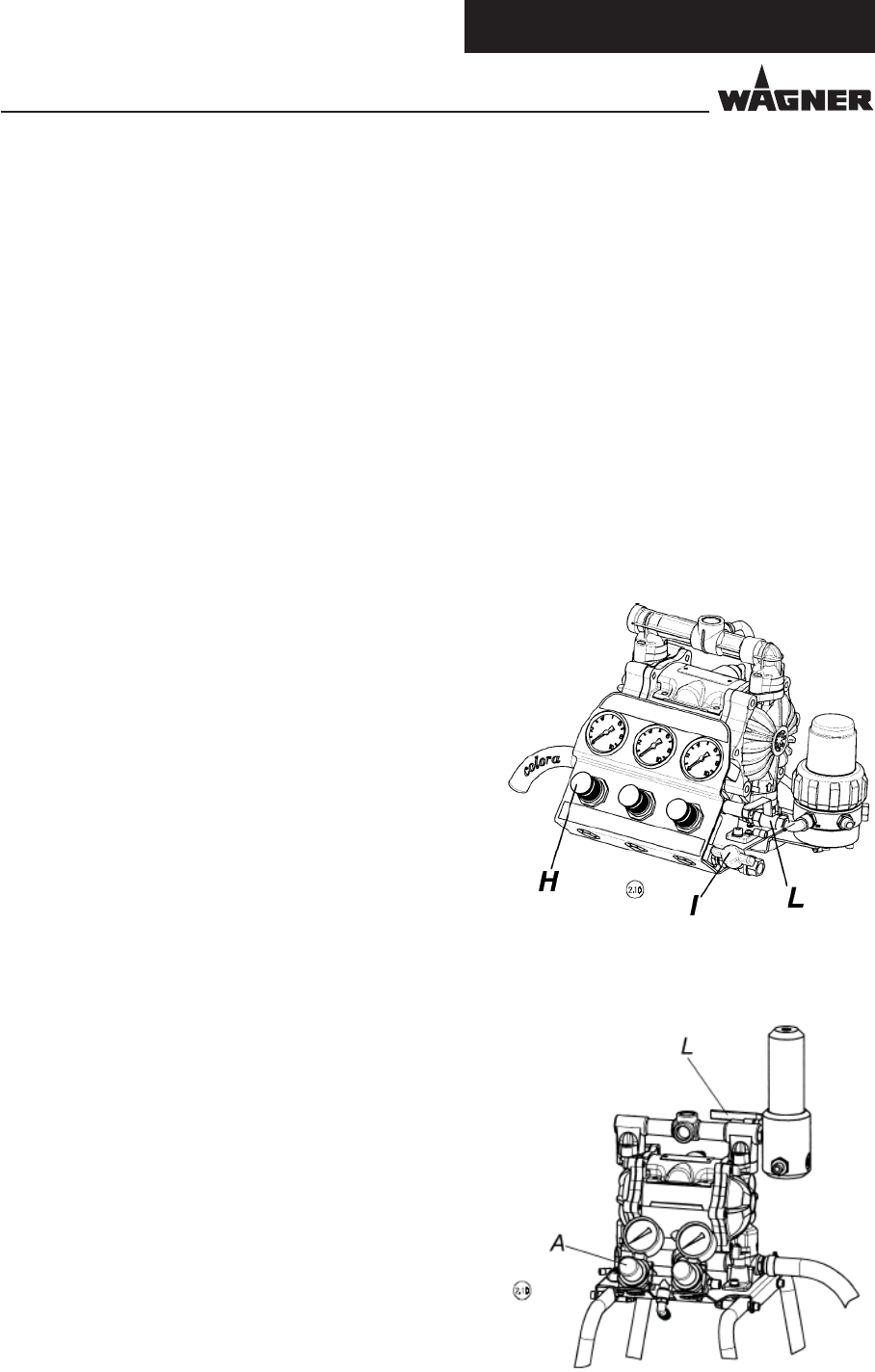

Emergency stopping for 2301838

To stop the equipment in good time, close the air on-off valve

on the feeding line or release pressure through the regulator

knob (A) thus stopping the feeding air to the motor.

Carry out the pump priming operations correctly to prevent

pressurized air babbles from being trapped.

Pneumatic pumps can keep all components connected to the

delivery under pressure, even when the driving air feed is clo-

sed. To prevent harm to people, as well as to avoid damaging

things or the environment, after stopping the pump it is best

to release the pressure by keeping the delivery valve open or

opening the recycling valve (L).