18

ZIP52 FINISHING - PF .

OPERATING MANUAL

EDITION 01 /2010 PART NO. ZZB012ENG

4.4 FUNCTIONING

7!2.).'

/VERPRESSURE

2ISKOFINJURYFROMBURSTINGCOMPONENTS

.EVERCHANGETHESAFETYVALVESETTING

3)()??'"

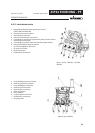

4.4.1 PUMP

A Diaphragms

B Connecting shaft

C Check valves

M Driving chambers

P Pumping chambers

Q Air motor

R Inversion valve

General information

The principle lying behind the functioning of diaphragm pumps driven by compressed air

is just as simple as it is effective. Two diaphragms (A), which are connected to one another

by means of a connecting shaft (B) so as to be integral, divide two adjacent capacities into

four chambers. The inner ones function as driving chambers (M) while the outer ones func-

tion as pumping, chambers (P). A pneumatic distributor alternately conveys compressed air

into one of the driving chambers, thus producing the diaphragms movement and conse-

quently causing one of the pumping chambers to empty (as a result of volume decrease),

while at the same time the other fi lls up (as a result of volume increase). A series of check

valves (C) prevents the liquid from fl owing back, thus producing the suction and delivery

phases in each pumping chamber.

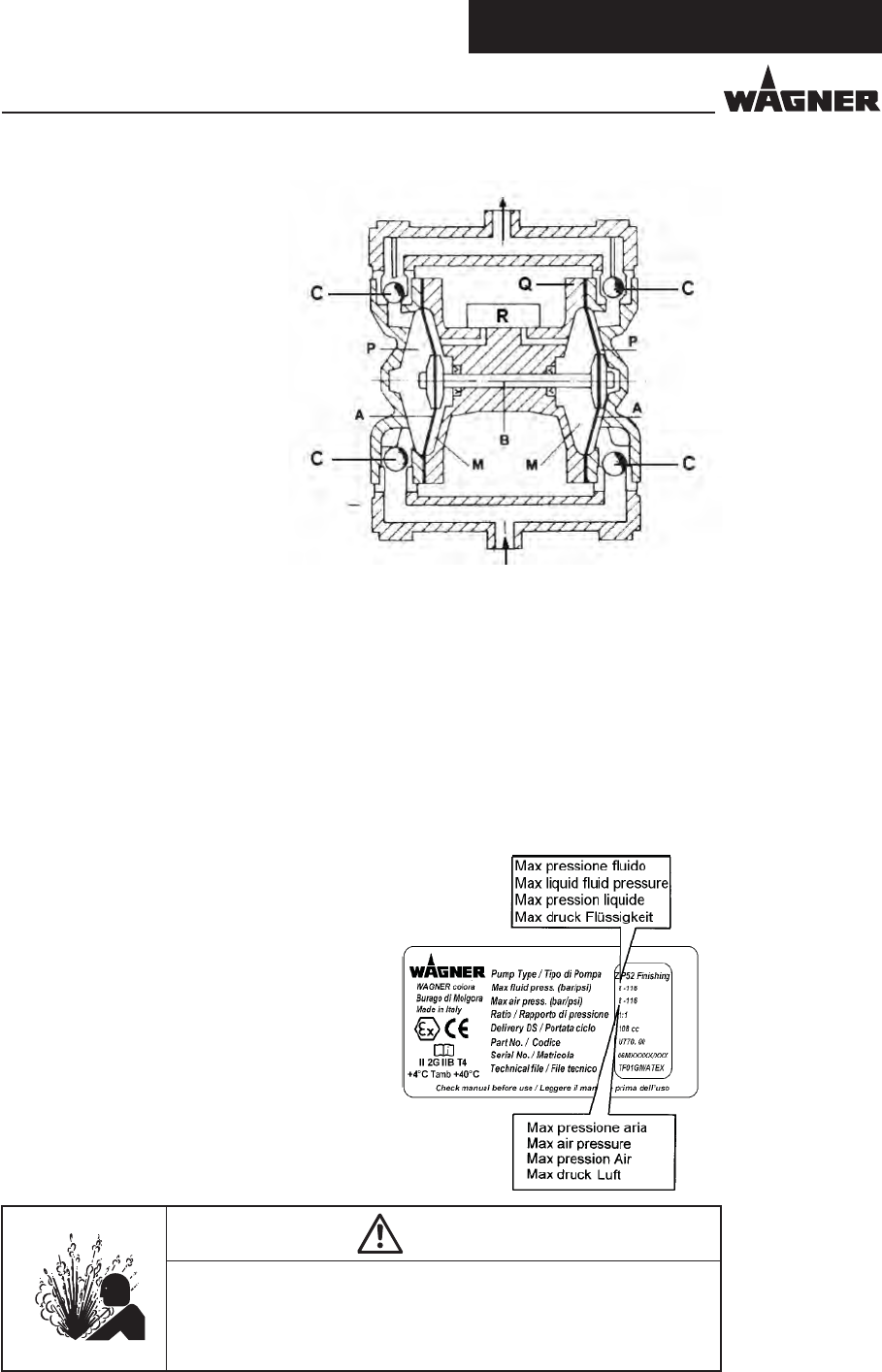

Air motor (Q)

The pneumatic motor must be powered

at a pressure not exceeding the value giv-

en on the plate. Each component linked

to the pump outlet must have an operat-

ing pressure equal to or higher than the

pressure generated by the pump itself.

This fi nal pressure is given on

the plate (see the picture on the right).