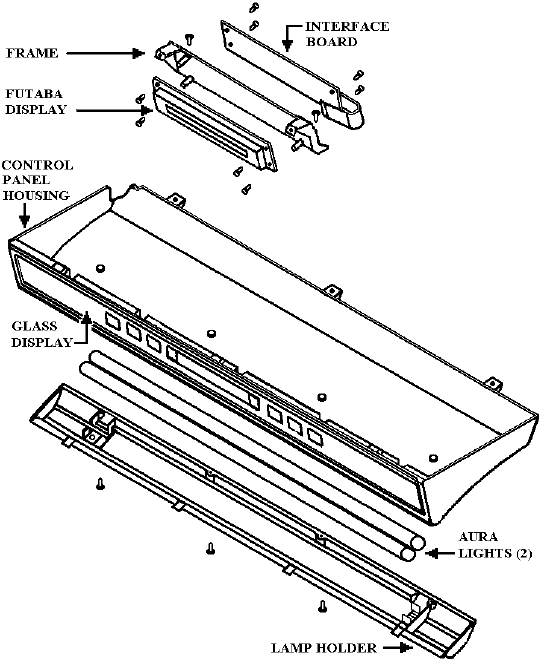

CONTROL PANEL ASSEMBLY

The wine cooler is equipped

with a control panel

conveniently located in the top

front of the top compartment

of the wine cooler. From this

point the user can operate all

functions of the wine cooler’s

temperature management and

various electronic features.

The control panel housing is

constructed of injected molded

plastic. A glass keyboard is

fastened to the housing by

means of snap clips that are

incorporated into the molded

housing. The keyboard is then

secured in place with an

adhesive. The keypad utilizes

a special technology that

senses mass. When the user

places a finger on the glass

surface at designated “button”

locations the control

recognizes this and converts

this to an electronic signal.

This signal is then processed by the wine cooler’s control that promptly results in a

change of temperature settings or some of the other wine cooler electronic features.

On the underside of the control panel a means for attaching two light bulbs is molded in

place. The light tubes are installed into a separate lamp holder, which is then attached to

the control panel by four “molded in” clips and four screws.

Mode of operation: Microprocessor based 3 – channel temperature / logic control.

Normal cooling operation: Control will independently read and regulate the average

temperatures of each chamber to its corresponding set point as shown on the vacuum

florescent display (“VFD”). When cooling is called for, the zone valve will energize and

the compressor will energize 60 seconds later. Only one zone valve / fan can be

energized at a time. Chamber 1 will take precedence over chamber 2, which will take

precedence over chamber 3 in the event that more than one chamber is calling for cooling

at the same time. Each chamber will run for a maximum of 10 minutes after which it will

switch to the next chamber requiring cooling. When a chamber reaches 1º below set

temperature the zone valve is de-energized. The control will energize the compressor

6