PAGE 16

GENERAL INSTRUCTIONS

Before seasonal start up it is advisable to have a competent service agency check the

boiler for soot and scale in the flues, clean the burners, and check the gas input rate to

maintain high operating efficiency.

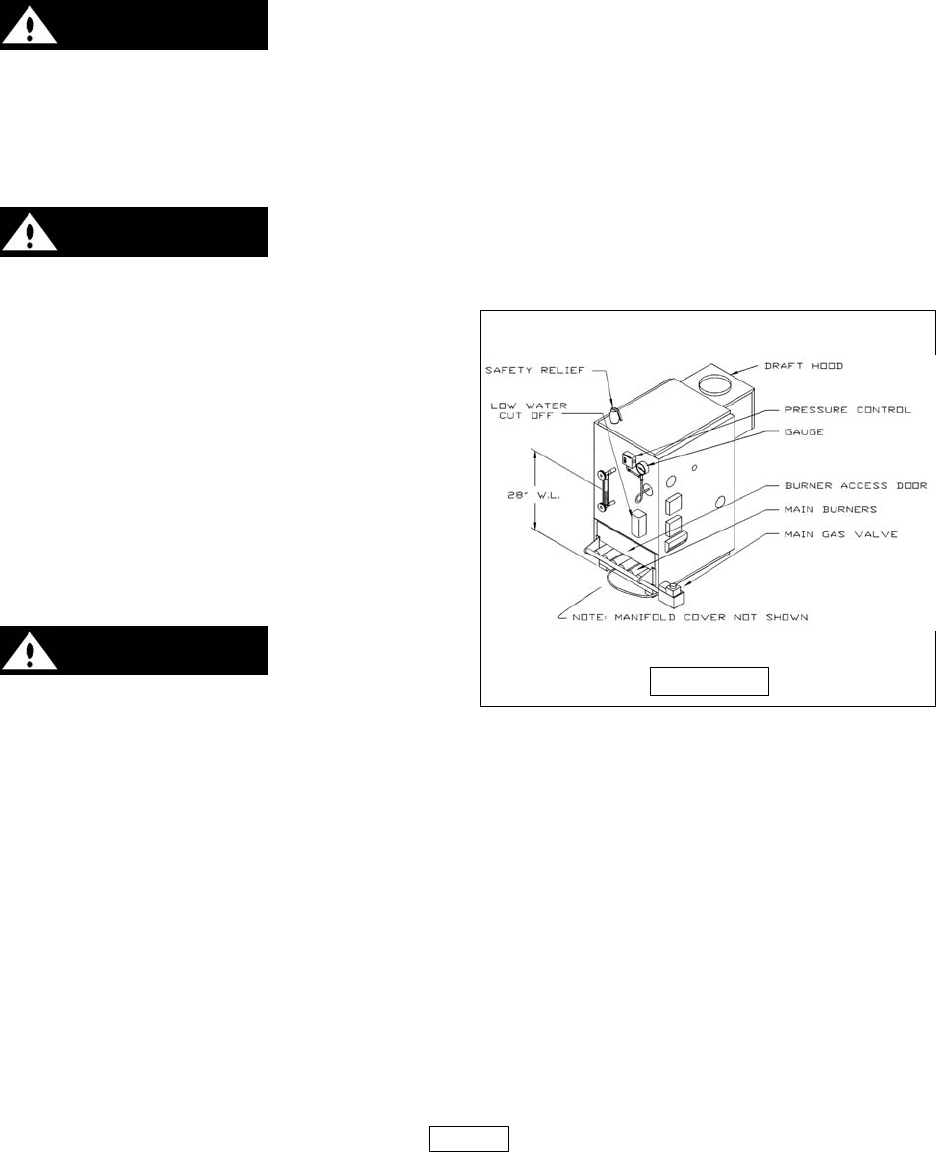

On steam boilers make certain the boiler is filled to the water line as indicated in figure

15. The gauge cocks should be normally open. To remove dirt from the gauge glass the

petcock may be opened to flush out the glass.

WARNING: DISCHARGE WILL BE BOILING HOT WATER.

The radiator valves on a one-pipe steam system must be either wide open or tightly shut.

Do not attempt to regulate room temperature by partially closing the radiator valve.

Air vents on steam radiators and the supply main release air from the system. If radiators

do not heat satisfactorily, make sure the air vents are clean and operational.

The lever of the safety valve, shown in figure 15 below, on the boiler should be operated

periodically to make sure that it is functioning properly.

WARNING: DISCHARGE WILL BE BOILING HOT WATER AND STEAM.

The safety valve should open before the steam pressure exceeds the 15 lb. reading on the

gauge, (figure 15 to right). If this pressure is

exceeded and the safety valve does not

open, it must be replaced. If the safety valve

leaks steam when the boiler is operating at

normal pressures, it should be immediately

replaced. Corrosion can build up rapidly at

the valve seat and prevent its functioning as

a safety device.

During the heating season the drain cock,

on the bottom rear of the boiler, should be

opened once a month to flush out the boiler

so the device will be free to function properly.

Use a pail to catch the discharge.

WARNING: DISCHARGE

WILL BE BOILING HOT WATER.

If the water in a steam boiler appears to be dirty or oily, or the water level in the gauge

glass fluctuates considerably, the boiler should be cleaned and skimmed (See page 18 for

instructions). A competent service person will use approved cleaning compounds and

properly clean and flush out the boiler. He/she should also clean or replace air vents and traps,

clean flue passages and check for proper operation of all controls and safety devices.

The venting system should be inspected at the start of each heating season. Check the

vent pipe from the boiler to the chimney for signs of deterioration by rust or sagging joints.

Repair if necessary. Remove the vent pipe at the base of the chimney or flue and, using

a mirror, check for obstruction.

The boiler flue gas passageways may be inspected by a light and mirror. Remove the

burner access door, (figure 15 above). Place a trouble lamp in the flue collector through the

draft-hood relief opening. With the mirror positioned above the burners, the flue gas

passageways can be checked for soot or scale.

FIGURE 15