52 WSHP-SVX01D-EN

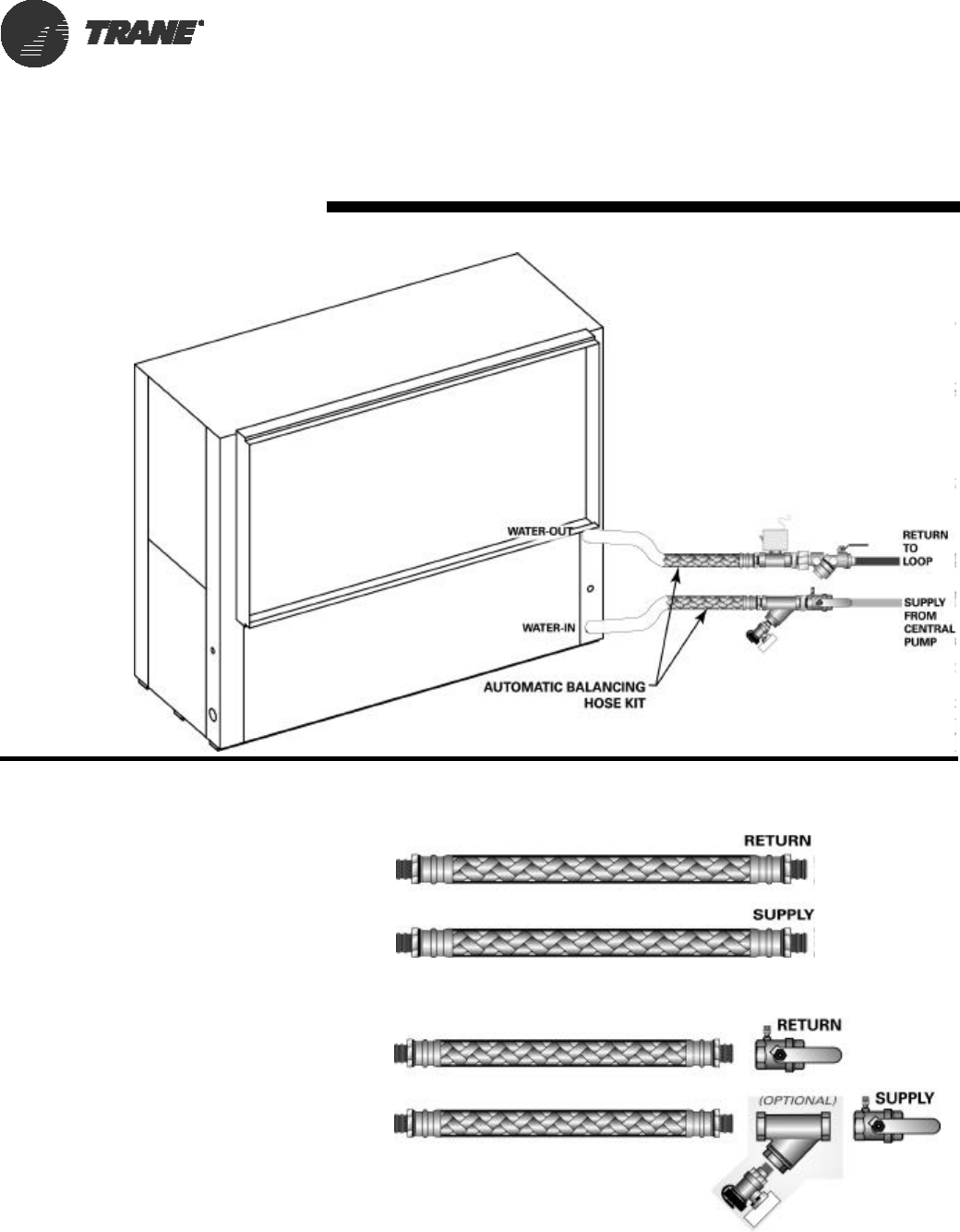

Supply/Return Pipe Connections

Connect the supply and return hoses to

the water-inlet (from supply) and

water-outlet (to return)

of the unit. For

vibration isola-

tion, it is rec-

ommended

that flexible

steel braided

hoses be in-

stalled instead

of hard piping

the equipment

to the main

loop system.

Figure 7 shows

connection of a

Hays Measurf-

lo balancing

hose kit to the

water-in and

water-out of a

vertical unit.

Types of Hose Connections

Whether installing the units in a central

pump (main/auxiliary pump for the en-

tire zone) design, or as a distributed

pump (1-pump per unit) design, a shut-

off device and flexible hose is recom-

mended to transition from the hard pip-

ing of the closed or open loop water

system to the unit. There are multiple

hose combinations which may be used

to fit the design or specification criteria

for the installation.

(1) A steel braided hose without a shut-

off device is the least expensive means

of connecting the heat pump to the sup-

ply/return water loop.

(2) With the addition of a shut-off device

on the supply and return of the system,

the unit may be isolated during service

or maintenance situation. This system

may be installed as a wide open (full wa-

ter flow to the equipment) design, or

manually balanced by utilizing the pres-

sure/temperature ports on the top of the

ball valve/shut-off device.

Installation

Option 1: Flexible hoses

Option 2: Flexible hoses with ball valves

Note:

The Figure 7 example

incorporates the Hays

Measurflo balancing hose kit and a 2-posi-

tion isolation valve into the system design.

An isolation valve is often used in variable

speed pumping applications. The isolation

valve is designed to stop water flow to the

unit during non operation times. This al-

lows the loop water pumps to run only

when a requirement for pumping is needed

for greater energy efficiency of the overall

system design.

Figure 7: Supply/Return pipe connections