8

Toshiba

2-2-2. Processing of piping materials

When installing refrigerant pipe, prevent water or dust from entering the pipe, and do not use oil other than lubricant

used for Air to Water Heat Pump. Make sure that no refrigerant leak occurs.

If piping needs lubrication, use lubricating oil whose water content is removed.

After the oil is put in, be sure to seal the container with airproof cover or other covers.

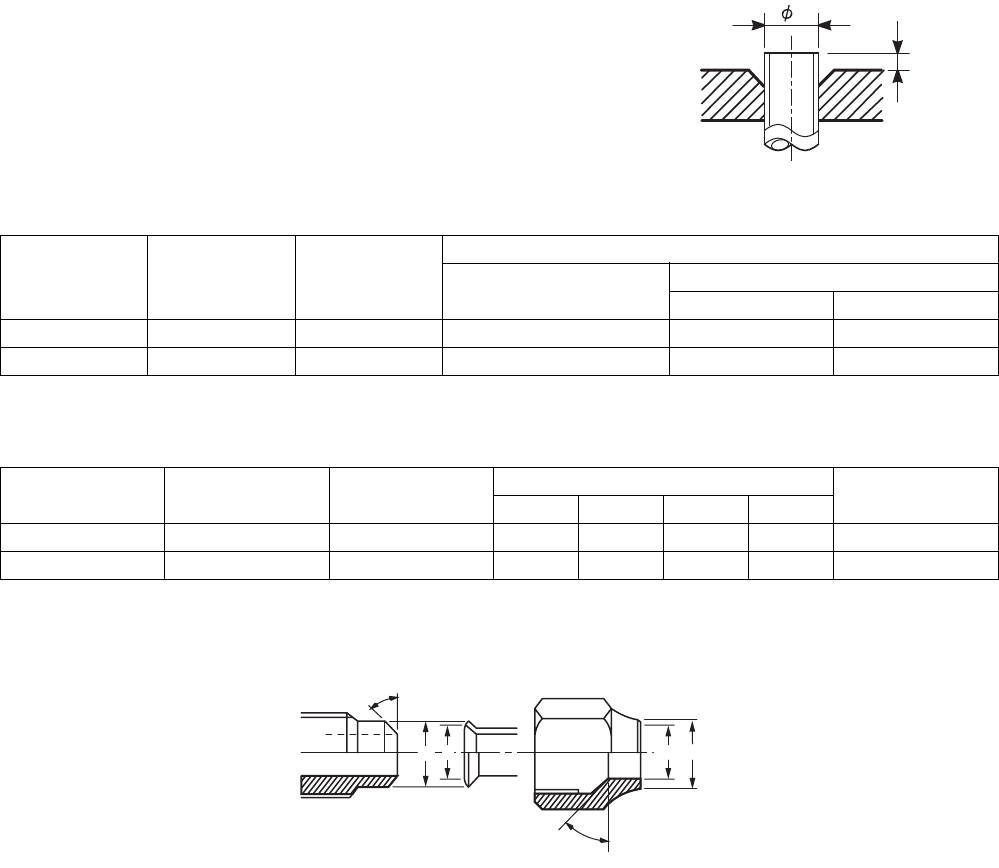

Flare and precautions

1) Cut a pipe.

Cut slowly with a pipe cutter so that the pipe is not distorted.

2) Remove burr and flaw.

A burr or flaw in a flare part may cause refrigerant leak. Remove carefully all the burrs, and clean up the

cut ends before installation.

3) Insert a flare nut.

4) Flare

Check that the clasps and copper pipe are clean. Flare

correctly using the clasp. Use a flare tool for R410A or the

conventional one. Flare processing dimension varies

depending on the flare tool type. When using the

conventional flare tool, use a gauge for size adjustment

to secure the A dimension.

Table 2-2-3 Flare processing related dimension for R410A

Table 2-2-4 Dimension of flare for R410A and flare nut

Figure 2-2-2 Relationship between flare nut and flare surface

Nominal

diameter

Outer diameter

(mm)

Wall thickness

(mm)

A (mm)

Flare tool for R410A

clutch type

Conventional flare tool

Clutch type Butterfly-nut type

3/8 9.52 0.8 0 to 0.5 1.0 to 1.5 2.0 to 2.5

5/8 15.9 1.0 0 to 0.5 1.0 to 1.5 2.0 to 2.5

Nominal

diameter

Outer diameter

(mm)

Wall thickness

(mm)

Dimension (mm)

Flare nut width

(mm)

ABCD

3/8 9.52 0.8 13.0 13.2 9.7 20 18

5/8 15.9 1.0 19.1 19.7 15.9 24.5 26

A

D

Figure 2-2-1

Flare dimension

DCB A

45° - 46°

43° - 45°

+00A09-002_01EN_SVM_ALL_Air_to_Water.book Page 8 Monday, October 5, 2009 2:09 PM