143

Toshiba

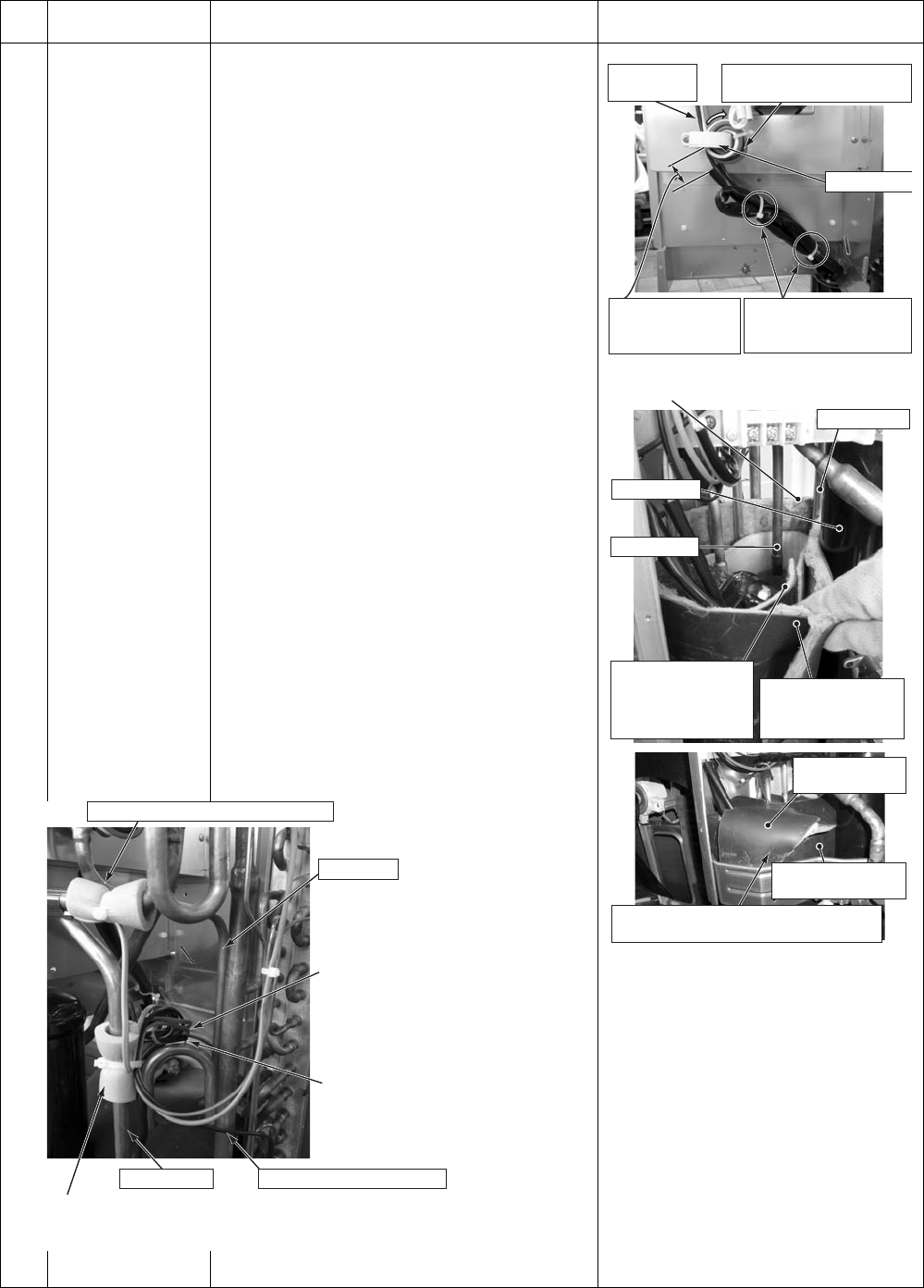

6 Compressor

Compressor lead

2.Attach the compressor

1)Attach the compressor in the reverse order of the

removal.

Note)

• Be sure to replace the compressor lead after the

compressor replacement. (Compressor lead

spare parts code: 43160591)

At this time, wind the ferrite core with the

compressor lead for 4 times.

Bind the compressor lead that is long with a

commercially available binding tie. When doing

this, be careful for the compressor lead not to

contact the discharge pipe.

• Fix the removed sensors and pulse motor valve

coil lead to the outlet and suction pipes through

the piping cover by using a binding tie. At this

time, be careful for the sensors and pulse motor

valve coil lead not to contact the discharge pipe.

(To fix the sensors and leads, use the black

piping cover for heat resistance and a

commercially available binding tie for heat

resistance.)

• Attach the soundproofing board (Inward

winding, Outward winding), as shown in the right

figure, through between the compressor and

between the piping and parting board.

• Place the compressor lead and the compressor

case thermostat so that they fall into between

the inward winding and outward winding of the

soundproofing board.

No.

Exchange parts

name

Work procedure Remarks

Black piping cover for heat resistance,

and Binding tie for heat resistance

Sensors (TL, TO, TE, TD, TS)

Pulse motor valve coil lead

Piping cover, Binding tie

Sensors (TL, TO, TE, TS)

Pulse motor valve coil lead

Keep sensors away

for not contacting outlet pipe

Pulse motor valve coil leadSuction pipe

Piping cover, Binding tie, TS sensor

Outlet pipe

Place soundproofing board (Outward winding)

through between suction pipe and accumulator

Compressor

lead

Ferrite core

Suction pipe

Accumulator

Soundproofing

board (Upper)

Soundproofing board

(Outward winding)

Do not make gap between soundproofing

boards (Upper and Outward winding)

Header pipe

Overlap soundproofing

board (Outward winding)

at this position

Place soundproofing

board (Inward winding)

through between suction

pipe and header pipe

0 to 50

(Compressor lead

positioning standard)

Bind the lead at 2 positions

with a commercially

available binding tie

Wind ferrite core with

compressor lead for 4 times.

+00A09-002_01EN_SVM_ALL_Air_to_Water.book Page 143 Monday, October 5, 2009 2:09 PM