151

Toshiba

6 Compressor

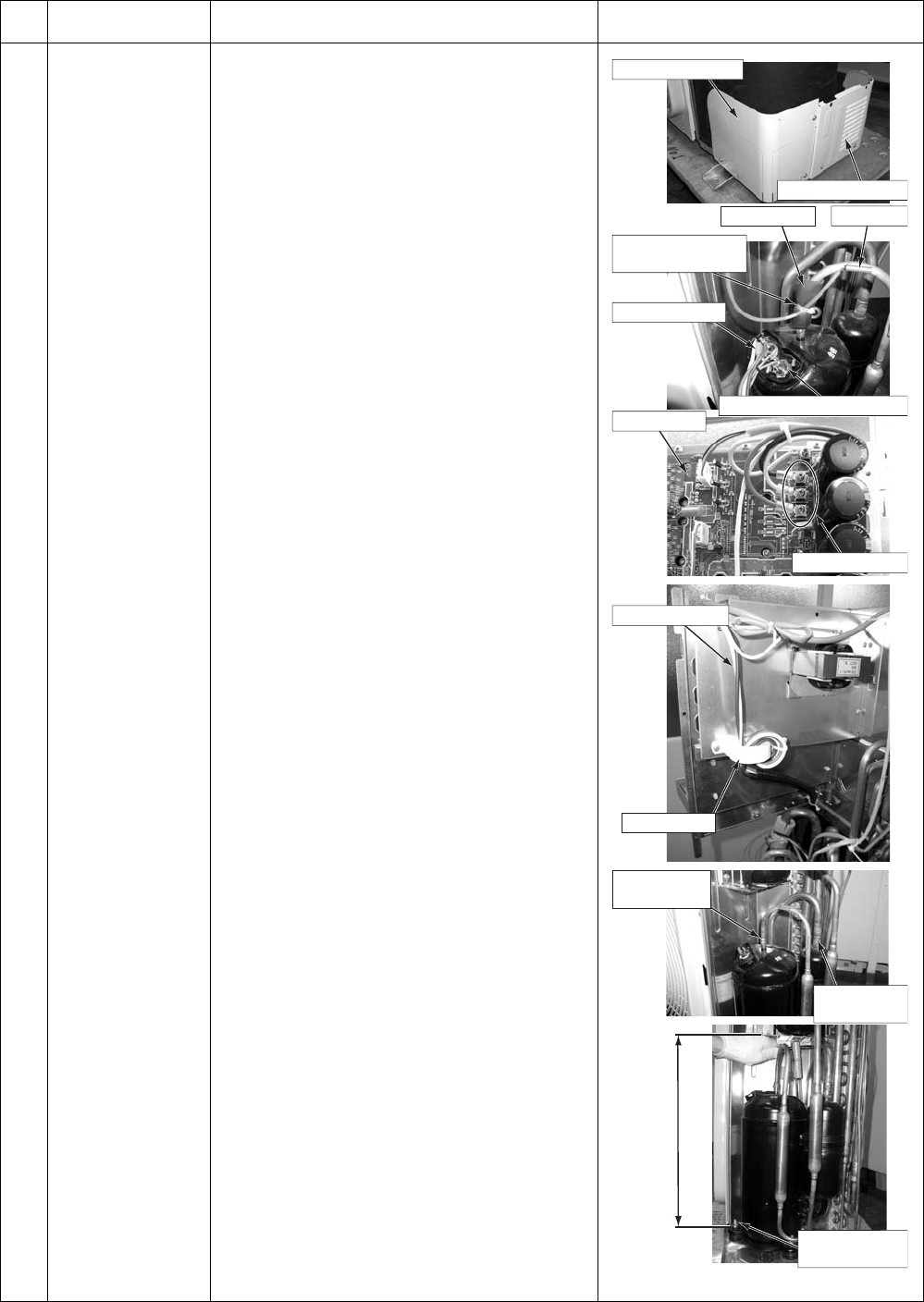

Compressor lead

1.Remove defective compressor

1)Perform refrigerant gas recovery.

2)Perform the step 1-1 and step 3.

3) Remove the piping panel (Front).

Remove screws of the piping panel (Front) and

bottom board.

(Hex Ø4 × 10, 2 screws)

Remove screws of the piping panel (Front and

Back).

(Hex Ø4 × 10, 1 screws)

4)Remove the piping panel (Back).

Remove screws of the piping panel (Back) and

bottom board.

(Hex Ø4 × 10, 2 screws)

5)Remove the soundproofing board. (Upper, Inward

winding, Outward winding)

6)Remove the compressor terminal cover, and then

remove the compressor lead and compressor

case thermostat.

7)Remove the TD sensor fixed to the discharge

piping.

8)Remove the compressor lead. (Leave the ferrite

core attached to the electric parts box.)

Control board U: CN200 Red

V: CN201 White

W: CN202 Black

9)Remove the outlet and suction pipes connected to

the compressor by using a burner.

WARNING

When removing the piping by burning the solder,

take enough care for a fire going off at the

moment the wax melts if oil remains inside the

piping.

Note)

Do not make fire flame contact with the 4-way

valve and pulse motor valve.

(This may cause an operation failure.)

10) Pull out the discharge and suction pipes of the

refrigerant cycle upward.

11) Remove the compressor nuts that fix the

compressor to the bottom board. (3 nuts)

12) Pull the compressor out toward you.

Note)

The compressor weighs 20 kg or more.

Two people should be required to handle it.

No.

Exchange parts

name

Work procedure Remarks

Piping panel (Front)

Piping panel (Back)

450

TD sensor

Piping cover

Binding tie

(for heat resistance)

Remove

(Outlet pipe)

Compressor nut

(3 nuts)

Remove

(Suction pipe)

Compressor case thermostat

Compressor lead

Compressor lead

Compressor lead

Ferrite core

Control board

+00A09-002_01EN_SVM_ALL_Air_to_Water.book Page 151 Monday, October 5, 2009 2:09 PM