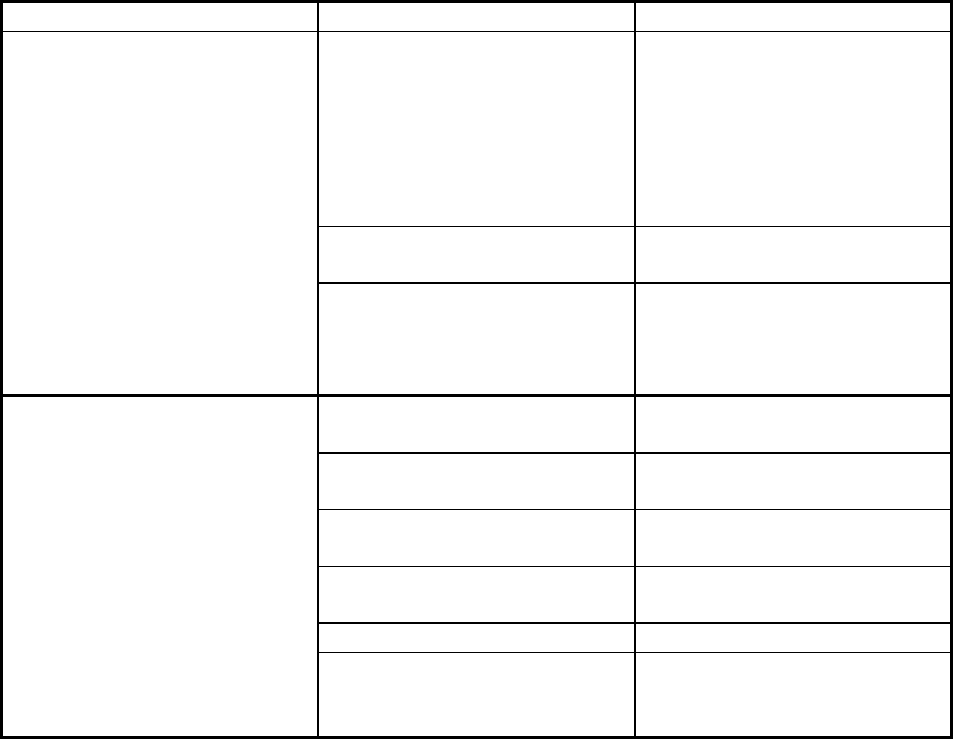

350-2100 cfm Dryers Chapter 7: Troubleshooting 54 of 58

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

Material in drying hopper

cakes, or meltdown occurs.

A. Process temperature set

too high due to operator

error.

A. Check resin

manufacturer's data sheet

for proper drying

temperature. Make sure

plant personnel are aware

of the correct process

temperature Set Point.

B. High temperature alarm

not set properly.

B. See Section 5-5.

C. Process set point is out

of acceptable range.

C. Restore temperature

controller to factory pre-

sets. Auto-Tune if

necessary. See Sec. 6-11.

Poor Dew Point

Performance.

A. Burned out regeneration

heater.

A. Repair or replace.

B. Contaminated or worn

out desiccant.

B. Replace.

C. Leaking process air

hoses.

C. Repair or replace.

D. Dryer is being operated

beyond its capacity.

D. Check dryer and drying

hopper sizing.

E. Bad dew point sensor. E. Replace.

F. Fouled dew point

sensor manifold.

F. Clear obstruction. Air

should flow freely through

sensor.