350-2100 cfm Dryers Chapter 2: Functional Description 14 of 58

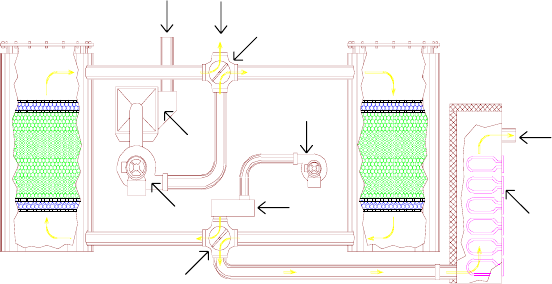

When a desiccant bed is on-

line, it absorbs moisture

from the process air. In

time, the bed becomes

saturated with moisture and

needs to be regenerated.

The dryer automatically

redirects the process

airflow to the second bed,

and starts the regeneration

cycle on the first bed.

During regeneration, air is

heated to approximately

550°F and forced through

the desiccant bed. The moisture driven off the bed is bled to the atmosphere.

If the temperature of the air bled to atmosphere (bleed temperature) is measured, a rise can be

observed after a period of time. This condition, called "bed breakthrough" indicates that the

bed is dry. At bed breakthrough, the bleed air temperature peaks between 350°F and 400°F.

Dryer models 350 through 2100 dryers are equipped with the Dewpoint Extend feature. The

regeneration heaters turn off automatically on bed breakthrough for additional energy

savings. A 550°F regeneration temperature will dry the desiccant beds sufficiently to produce

process air dewpoint of -40°F. In a properly sized system, this ultra-low humidity level will

be more than adequate to dry plastics to as little as .003% moisture.

2-8 Specifying a Drying System

There were many variables considered in the selection of your drying system, including: type

of materials, residence time, throughput of the extruder or injection molding machine,

ambient air moisture and temperature, and the altitude at the processing site. Should your

operating environment change, the manufacturer can advise you on necessary equipment and

process time and temperature modifications.

Process Return Air

From Drying Hopper

Process

Filter

Assembly

Process

Blower

Bleed

Upper

Control

Valve

Lower

Control

Valve

Regeneration

Blower

Process

Delivery

Air

Process

Heaters

Desiccant

Bed

Regeneration

Heater

Desiccant

Bed

Figure Two:

Airflow Diagram