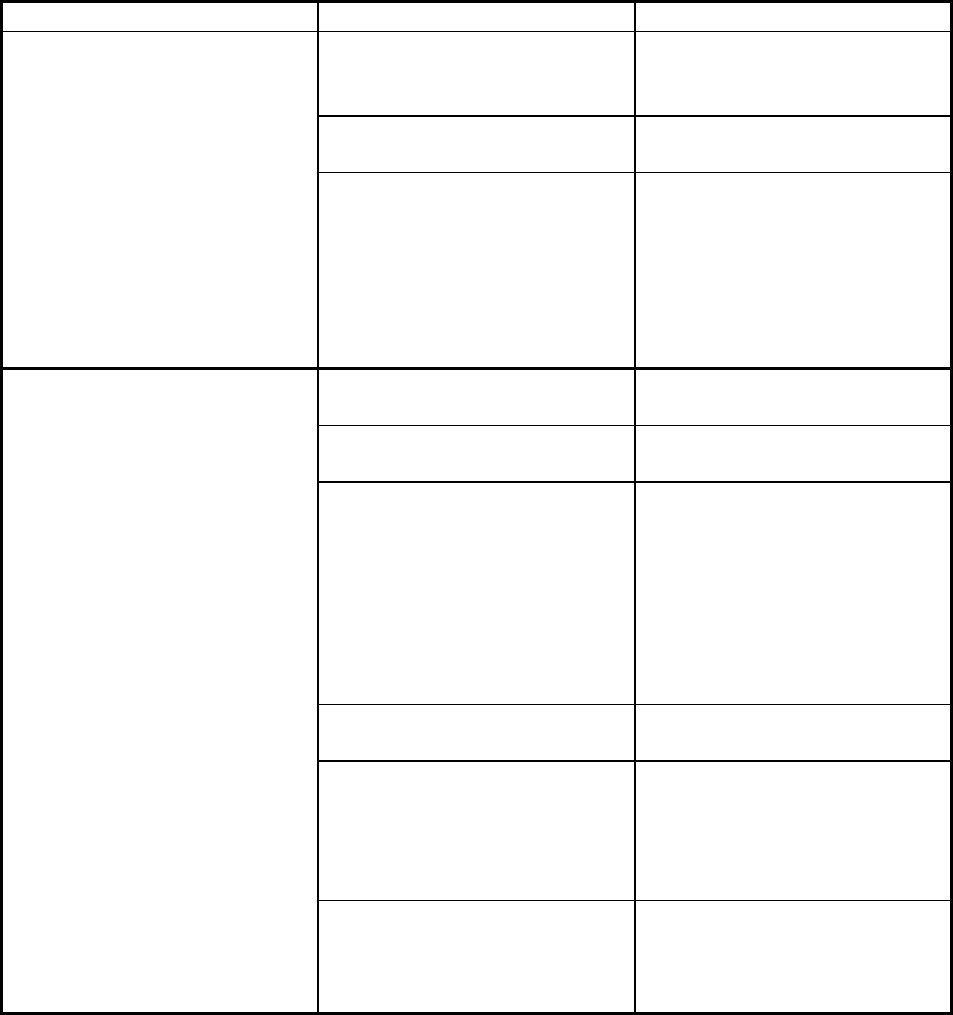

350-2100 cfm Dryers Chapter 7: Troubleshooting 53 of 58

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

Loss or reduction of

process air temperature.

A. Process heaters are

faulty.

A. Check for open or

shorted heaters. Replace if

required. Check the fuses.

B. Solid-state temperature

controller faulty.

B. Replace.

C. Process temperature

was adjusted in error by

plant personnel.

C. Make sure that plant

personnel are aware of the

proper temperature

setpoint. A sign posted next

to the control would be

helpful.

Loss or reduction in drying

capacity.

A. Process heaters are

faulty.

A. Replace.

B. Desiccant beds are

contaminated.

B. Replace desiccant.

C. Material being dried

differs from material

specified at the time of

purchase.

C. Drying systems are

designed for the material

which was originally

specified. Different

materials may need a

longer residence time or

different drying

temperature.

D. Break in flex hose

to/from drying hopper.

D. Inspect for air leaks;

replace if necessary.

E. Airflow valves sticking

or failing to shift.

E. Check for proper

operation of linear valve

actuator. Check fusing.

Repair or replace if

necessary.

F. Blower fins filled with

dust or contaminants.

F. Remove blower

sideplate, clean baffles,

replace. Replace filter

elements.