350-2100 cfm Dryers Chapter 6: Maintenance 40 of 58

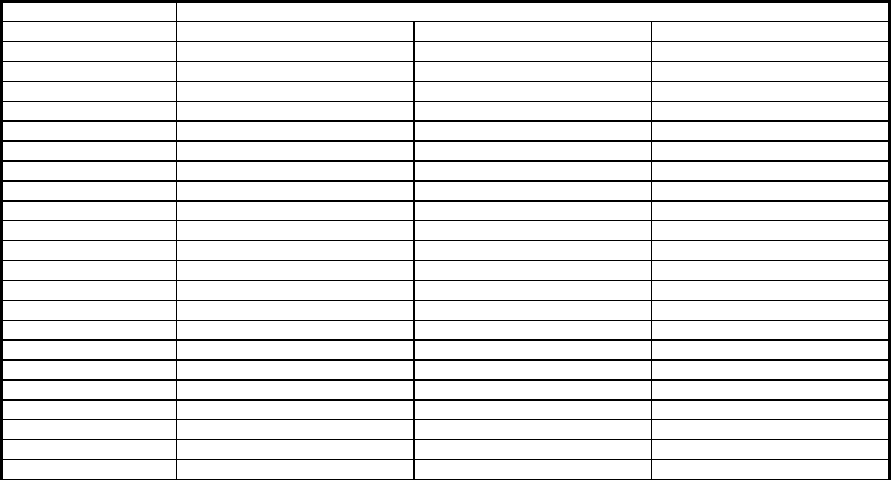

Figure 6: Desiccant Amounts Required

Dryer Desiccant Required per Tower

Model Large Bead Small Bead Total

350 30 76 106

350-RT 30 76 106

425 30 90 120

425-RT 30 90 120

500 40 100 140

500-RT 40 100 140

600 40 120 160

600-RT 40 120 160

700 40 35 175

700-RT 40 35 175

850 120 120 240

850-RT 120 120 240

1000 120 130 250

1000-RT 120 130 250

1250 120 180 300

250-RT 120 180 300

1500 120 240 360

1500-RT 120 240 360

1800 120 310 430

1800-RT 120 310 430

2100 120 360 480

2100-RT 120 360 480

6-9 Process Heater Replacement Procedure

ACS dryers have a number of single phase Calrod-type heater elements wired in a delta formation.

They are mounted in the vertical compartment behind the right hand desiccant tower. The number and

wattage of the heaters varies with model, voltage, temperature range, etc., but the replacement

procedure is the same.

WARNING! Disconnect and lock out power before heater replacement.

1. Remove the bolts securing the process heater access cover.

2. Sketch the heater wiring configuration so the heaters may be re-wired properly. Heaters are

mounted on a common plate of three or six for easy maintenance.

3. Remove the jumper bars and wires for the heater plate assembly(ies) being removed or replaced.

4. Remove the bolts securing the heater plate assembly and slide out the assembly. Avoid damaging

the gasketing.

5. Remove individual heaters for replacement by removing the large brass nuts and washers.

6. Re-install the heaters and heater plate assemblies in reverse order, replacing gaskets if necessary.

Caution! Heater loops should not touch each other. "Hot spots" will lead to premature heater

failure.

7. Re-install the jumper wires and bars according to the sketch made earlier.

8. Re-secure the process heater access cover.