350-2100 cfm Dryers Chapter 3: Installation 18 of 58

; Keep the delivery (to the drying hopper) hose as short as possible to minimize heat

loss. Insulated hose is recommended and available for maximum energy savings.

; Do not use insulated hose on the return (from the drying hopper)

; Do not shorten the return hose. The return air to the blower must be 150°F or below.

; Make sure the hoses are not kinked.

; Drying hopper air inlet and outlet locations vary, but always connect the hoses so the

dry process air from the dryer enters the bottom of the drying hopper and flows out

the top to return to the dryer inlet.

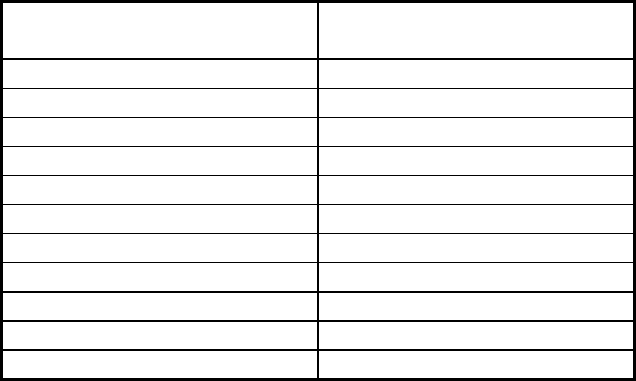

3-5 Aftercooler Cooling Water Connection

The Aftercooler cools the moist air returning to the dryer from the drying hopper. The

aftercooler can cool the return air from 250°F to about 150°F. This maintains the dryer's

efficiency and condenses unwanted plasticizers from the airstream.

1. Support both sides of the fitting when making the cooling water connections to

prevent damage to the aftercooler coil.

2. Connect 85°F water to the 1½" NPT inlet closest to the exiting air side of the

aftercooler coil. This will cool the process air about 100°F and raise the water-out

temperature about 10°F.

Aftercooler

Model

Recommended Cooling

Water Flow Rate (GPM)

AFT350 6.6 gpm

AFT425 10 gpm

AFT500 10 gpm

AFT600 13.2 gpm

AFT700 18 gpm

AFT850 18 gpm

AFT1000 22 gpm

AFT1250 22 gpm

AFT1500 25 gpm

AFT1800 25 gpm

AFT2100 25 gpm

3-6 Drying Hopper Air Trap

ACS’s exclusive air trap assembly in the top of the drying hopper prevents ambient air from

contaminating the material being dried.

5. Keep the material level above the bottom edge of the air trap for maximum

efficiency.

6. Use a hopper loader or vacuum conveying system to maintain the proper material

level.