Jaguar Model J-390

24

WATER PIPING

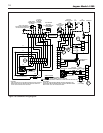

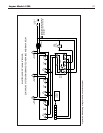

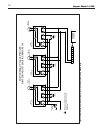

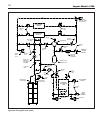

1. Connection of system to boiler:

P

rimary/secondary piping of the system is recommended, to

e

nsure the proper flow through the boiler. (See Figures 19

through 21). The boiler loop piping must be the same

diameter as the water outlet (supply) and inlet (return) piping

connections provided on the boiler, particularly on longer

loops. See page 2 for piping connection size.

2. Circulator Pumps:

The boiler loop piping must utilize the Taco 1400-20 circulator

t

hat is supplied with the boiler, to ensure the proper flow

t

hrough the boiler. Refer to Figure 18 for the boiler water side

pressure drop and Table 2 for the recommended pump

models for the domestic hot water system. Install the pumps

in the orientation shown in Figures 19 through 21.

3. Relief Valve(supplied with boiler):

Tee the relief valve into the boiler water outlet (supply) piping

as close to the water outlet (supply) connection as possible.

(See Figure 17). The relief valve’s discharge piping must be

the same size or larger than the relief valve’s outlet, and must

terminate 6” minimum from floor with a plain (no threads) end.

Place a bucket under pressure relief valve discharge. Make

sure discharge is always visible. DO NOT hard-pipe to drain

piping, or any place where freezing could occur. No shut-off

valve is permitted between the relief valve and boiler, or in the

discharge line.

4. Air Control System:

An appropriately sized diaphragm-type expansion tank must

be used to control the system pressure. See boiler volume

data on page 2, and the recommended location in Figures 19

through 21. An air vent is recommended to be installed on an

air separator in close proximity to the expansion tank.

5. Cold Water Fill:

A pressure reducing (fill) valve, with a shut-off valve upstream

of it, should be installed in close proximity of the expansion

tank. (See Figures 19 through 21). Use a back flow check

valve in the cold water supply as required by local codes.

6.

Low Water Cutoff:

On a hot water boiler installed abo

ve radiation level, the boiler

must be provided with a low water cutoff device at the time of

installation by the installer (see Figure 17 for piping

arrangement).

7. Water Treatment and Freeze Protection:

A good water treatment program will not only extend the

useful life of this boiler but it will also save much of the time

a

nd expense of repairs made necessary by preventable

o

ccurrences. A reputable water treatment company should be

consulted to evaluate and determine the best overall

treatment program for your boiler equipment.

The heat exchanger is made of aluminum, so the system

water must be maintained between 7.0 and 8.5 PH level.

T

horoughly flush the system, before connecting the boiler, to

r

emove any sediment or glycol.

Anti-freeze is sometimes used in hydronic systems to

protect against freeze-up in the event of power failure or

boiler shut down in the cold winter.

Use RhoGard

(Propyleneglycol with Pro-Tek 922 inhibitor) by Rhomar

Water Management, Inc.

Follow the manufacturer’s

instructions for proper application and proper mixture for

minim

um ambient temperature.

An

y use of anti-freeze

other than that supplied by Slant-Fin or specifically

approved and/or recommended for use by Slant-Fin

will void this warranty.

Never use Ethylene Glycol as it is toxic to humans.

Never use any types of automotive or standard gylcol freeze

protection fluids.

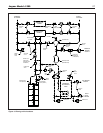

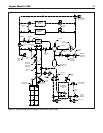

8. Piping a heating - cooling system to a water boiler and

chiller:

Figure 21 illustrates a method of piping a heating-cooling

system to a water boiler and a chiller. Hand valves (shown)

or automatic valves must be installed to prevent circulation

of chilled water in the boiler or hot water in the chiller.

The air control system and pressure control system must

operate with chiller only, or the boiler only, being valved to

the piping system. Separate control devices on the boiler

and chiller may be used, or a single set of air and pres-

sure controls on the common piping may be preferred.

If the boiler is used to supply hot water to heating coils in

air handling units, flow control valves or other devices

must be installed to prevent gravity circulation of water in

the coils during the cooling cycle.