Bobcat Models B-120A and B-200A

9

3. The vent termination is in addition to the allowed

equivalent lengths.

4. Minimum vent length is 2 feet of straight pipe, plus the one

90˚ elbow that is required.

5. Vent length restriction is for both direct and non-direct

vent installations.

EXAMPLE: Boiler model B-120 is to be installed. The

combustion air is provided by air intake piping directly to the

boiler (direct-vent installation).The vent piping will be PVC

and installation location will require the use of 4 elbows for

the vent to run the termination. The air intake piping will also

be PVC, and also will require the use of 4 elbows.

In this case, the maximum straight pipe vent length that can

be utilized with the 4 elbows would be: 100’ - (4’ x 5’) = 80’.

Since the air intake pipe also is PVC and requires the use of

4 elbows, the maximum straight pipe air intake length that

can be utilized is also 80 feet.

If the air for combustion were taken from the boiler room

(non-direct vent installation), still the maximum straight vent

length would be 80 feet.

6

. The B-120 and B-200 boilers are equipped with a built-in

c

ondensation drain and trap.The trap must be filled with

water. DO NOT operate the boiler without filling the trap with

water to prevent flue gas discharge into space.The drain

must dispose of possibly large quantities of condensate,

which may require a neutralizing system. Refer to the

“Condensate Drainage” section of this manual. No additional

condensation drain and trap is required on the vent piping

system itself.

7

. The horizontal vent pipe must be sloped upward from the

boiler at a pitch of at least 1/4” per 1 foot of run, so that

the condensate from the vent system runs to the boiler

vent adapter pipe, then out the built-in condensation drain

and trap.

8. The horizontal vent and air intake pipes must be supported

with pipe straps, at intervals no greater than 5 feet, when

PVC/CPVC pipe is utilized.This support spacing applies

also to stainless steel vent pipe, unless the manufacturer’s

instructions permit otherwise.The vertical vent and air

intake pipes also must be supported, wherever the building

construction provides allowance for it, such as ceiling or

roof passage openings where a firestop and support or

braces can be affixed.

9. Minimum clearances of vent pipes from combustible

constructions must be maintained (see Page 4). No

clearance is required between the vent and air intake pipes

of this boiler.

10. Common venting with other appliances or another Bobcat

boiler is not allowed.

11. DO NOT install a vent damper or similar devices in vent

system or on the boiler.

12. DO NOT insulate venting system.

Heat-F

ab

, Inc. Saf-T Standard 3

elbow

Heat-Fab, Inc. Saf-T, tight radius elbow 6

ProT

ech System, Inc.

F

asNseal

6

Flex-L International, Inc. StaR-34 6

Z-Flex, Inc. Z-Vent 6

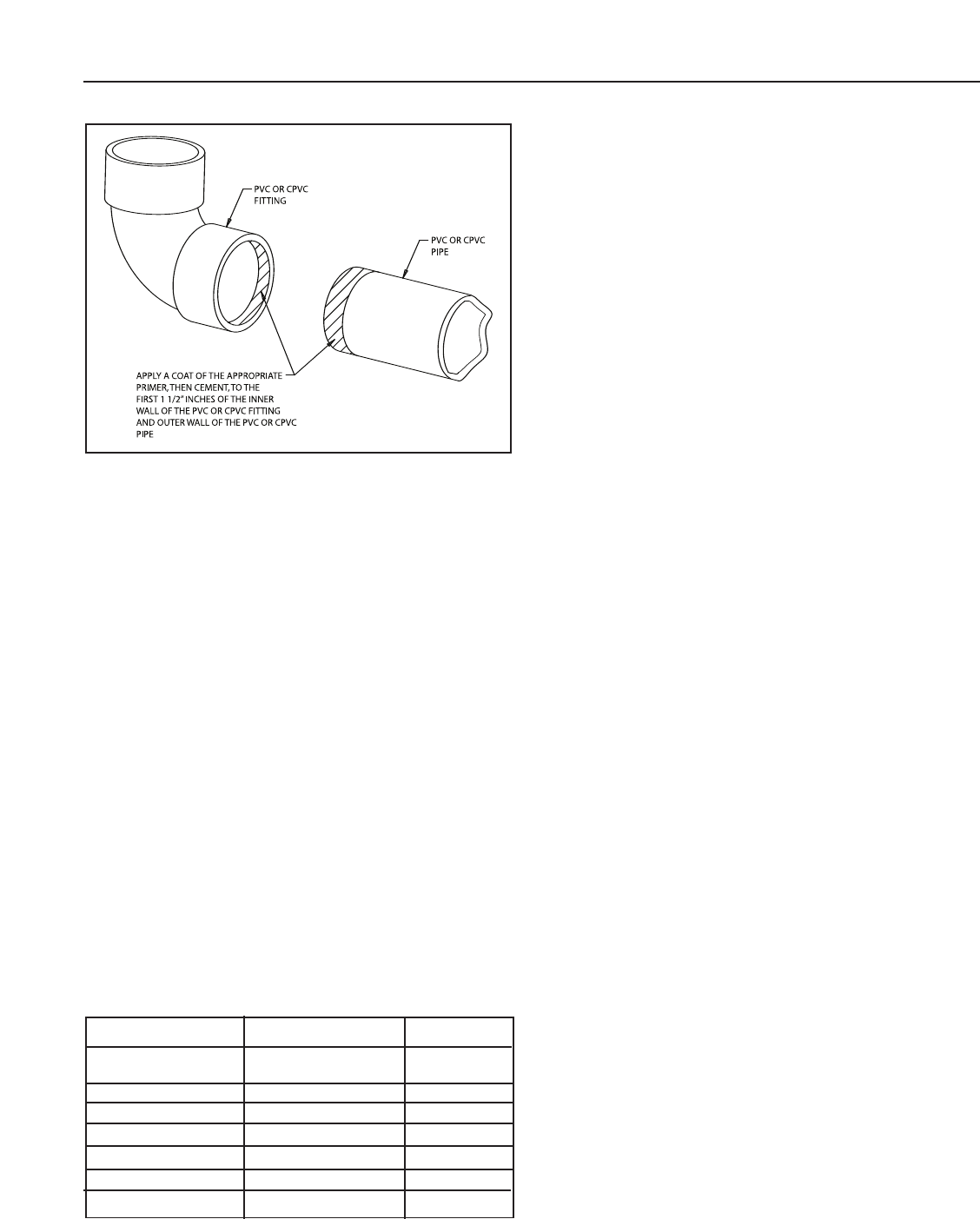

N/A PVC, Schedule 40 5

N/A

CPVC

, Schedule 40

5

Manufacturer

T

ype/System

Equivalent

Length (Feet)

Equivalent Length of Various 90-Degree Elbows

Figure 6.