MODU-FIRE® FORCED DRAFT

Gas-Fired Boiler Installation

3.12.2 Air Flow Adjustment

There are no required start-up or field adjust-

ments for air flow control. DO NOT attempt to

change any parameters in the blower speed con-

trol (inverter). The Modu-Fire FD uses a micro-

processor controlled variable frequency inverter to

control the speed of the blower. The air flow is set at

the factory. Should an error occur during operation,

the inverter will automatically reset after 30 sec-

onds. If the error recurs, log the flashing error code

and call for authorized service.

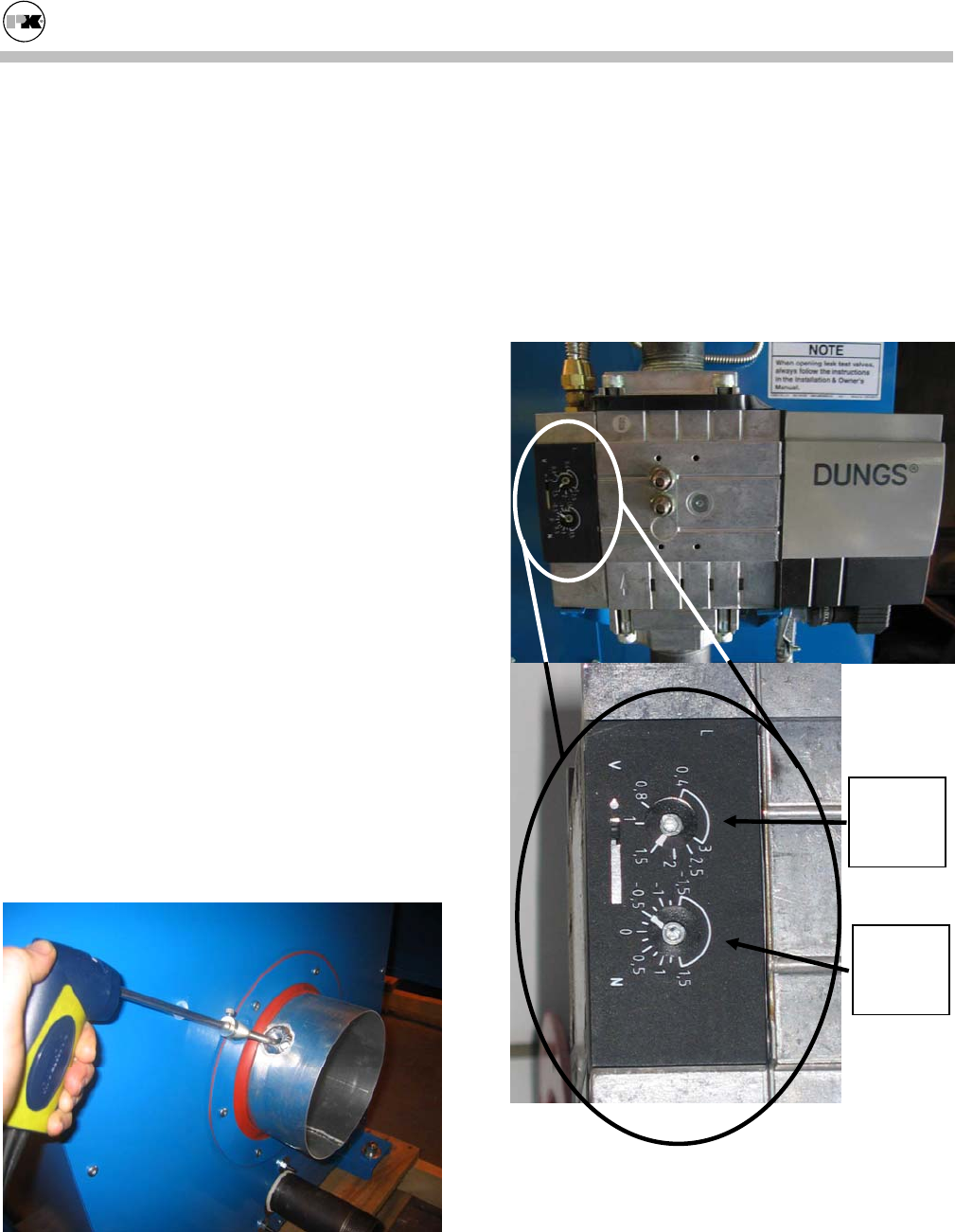

3.12.3 Fuel/Air Ratio Adjustment

The fuel/air ratio is controlled by the automatic air

gas ratio valve. This valve is adjusted at the fac-

tory to give 5.5-6% O

2

at high fire and 7.5-7.9%

O

2

at low fire in the exhaust gas. However, the

fuel/air ratio should be checked using a combustion

analyzer at start-up to verify that the combustion is

proper. Remove the vent plug and place the ana-

lyzer probe in the vent as shown. Be sure to replace

the plug after combustion has been set.

Start the boiler. Place the probe of a combustion gas

analyzer in the stack as shown. Using the toggle

switch on the boiler control panel, place the boiler in

High Fire. If the % O

2

is not within the range above,

the gas valve should be adjusted.

To adjust the gas valve on hi fire, turn the top screw

“V” clockwise to reduce the % O

2

or turn it counter-

clockwise to raise the % O

2

. Once high fire is ad-

justed, place the boiler in low fire using the toggle

switch and adjust the % O

2

if necessary, by turning

the bottom screw “N” clockwise to reduce the % O

2

and counterclockwise to increase the % O

2

.

Ratio (V)

Adjust at

Hi Fire

Bias (N)

Adjust at

Low Fire

21