MODU-FIRE® FORCED DRAFT

Gas-Fired Boiler Installation

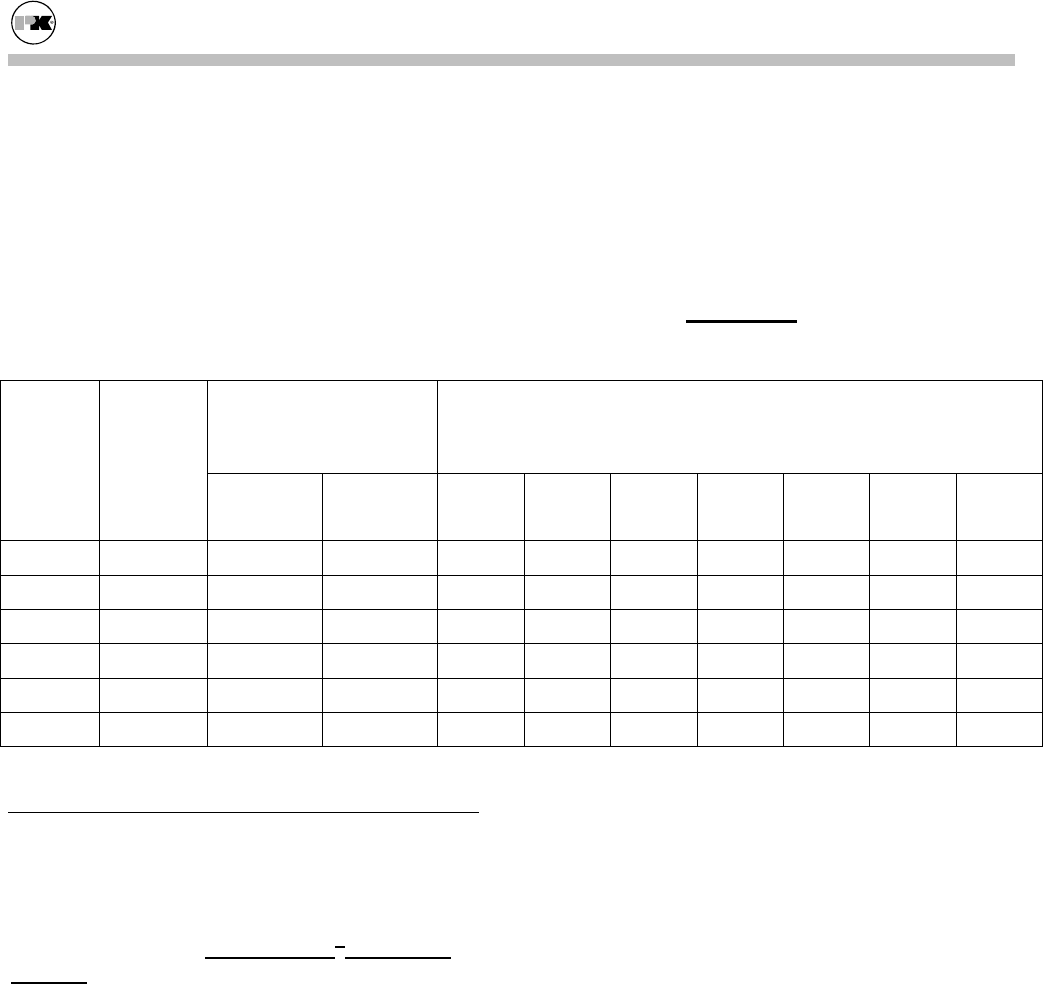

Pipe Capacity for Natural Gas

Notice: See Pipe Capacity for Natural Gas chart for required pipe size, based on overall length of

pipe from meter plus equivalent length of all fittings. Approximate sizing may be based on 1 cu-

bic foot of natural gas per 1,000 Btu per hour input, i.e., 500,000 Btu per hour requires about 500

cubic feet per hour. (See "Typical Boiler Operating Conditions,"

Section 4.3, for more informa-

tion.)

3.8

BOILER WATER PIPING

3.8.1 Piping Design

Water Flow in System

Ideal operation of the MODU-FIRE

®

FORCED-

DRAFT boiler would consist of a 20º F temperature

differential across the heat exchanger at high fire.

Insufficient flow may result in excessive short cy-

cling of the boiler and eventual damage or prema-

ture failure of the equipment.

Notice: The closing of the flow switch does not

prove that flow is adequate. It only indicates that

some flow is present. Proper flow rates are 90-

150 gpm for N/D1500MFD and 120-150 gpm for

N/D2000MFD boilers.

Minimum Return Water Temperature should be

greater than 130º F to avoid problems of condensa-

tion on the outside of the heat exchanger or in the

flue passages.

Proper flow rates and return water temperature may

be achieved through a combination of primary and

secondary flow loops. Multiple zones and pumps

may result in different flow rates at different times.

Consideration must be given to all possible condi-

tions and their consequences.

Piping with Refrigeration Machines

When used with a refrigeration system, the boiler

shall be installed so that chilled medium is piped in

parallel with the boiler. Valves should be installed

to prevent chilled water from entering the boiler

when the system is operated in the cooling mode.

Piping with Air Handling Units

The boiler piping system of a hot water heating

boiler connected to heating coils located in air han-

dling units, where they may be exposed to refriger-

ated air circulation, must be equipped with flow

control valves or other automatic means to prevent

gravity circulation of the boiler water during the

cooling cycle.

Equivalent Pipe Length Maximum Capacity in Cubic Feet of Natural Gas per Hour

Pressure Drop of 0.5 inch Water Column/Equivalent Length of

Pipe (in feet)

Nominal

Iron

Pipe

Size

(Inches)

Internal

Diameter

(Inches)

90º Ell

(Feet)

Tee

(Feet)

20

40

60

80

100

150

200

1-1/4 1.380 3.45 6.9 950

1-1/2 1.610 4.02 8.04 1,460 990 810

2 2.067 5.17 10.3 2,750 1,900 1,520 1,300 1,150 950 800

2-1/2 2.469 6.16 12.3 4,350 3,000 2,400 2,050 1,850 1,500 1,280

3 3.068 7.67 15.3 7,700 5,300 4,300 3,700 3,250 2,650 2,280

4 4.026 10.1 20.2 15,800 10,900 8,800 7,500 6,700 5,500 4,600

15