Series 8900SH Control Panel Operation And Installation Manual

Section 5 Sensor Troubleshooting

SECTION 5: SENSOR TROUBLESHOOTING

The wiring within the control panel from the Terminal Strip For Field Connections to the sensor

input terminals on the circuit board are completed at the factory.

Inside the panel is a second set of wires from each sensor to the “Terminal Strip For Field

Connections” that is generally completed by the electrical contractor.

Each pair of wires from a sensor is connected to the terminal strip inside the panel (for field

wiring) and from there to the sensor input terminals on the circuit board. Below is a list of

where the wires for each sensor are attached and the code that allows you to read the

temperature.

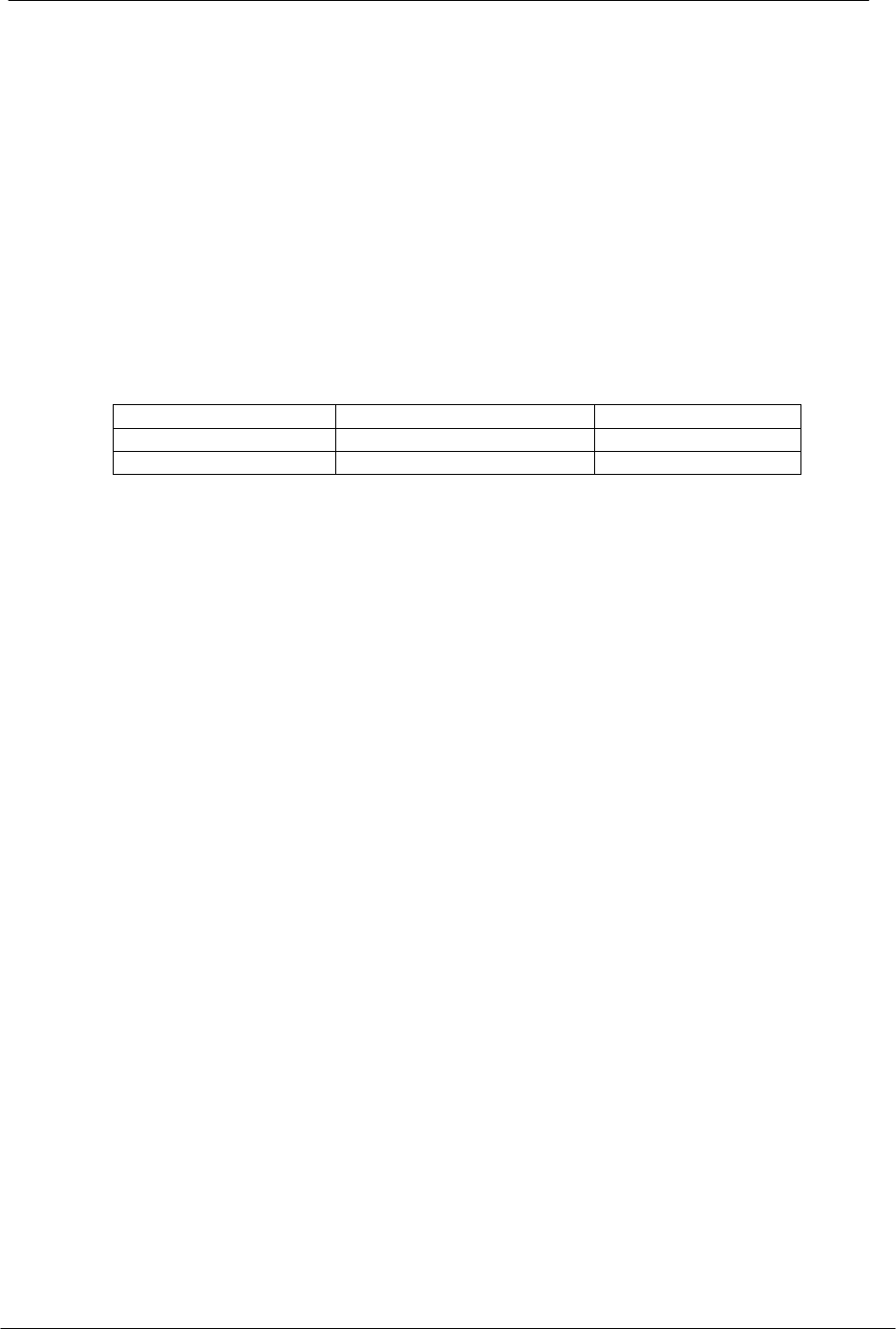

SENSOR LOCATION INPUT TERMINALS ENTER CODE

Outside Sensor S1 11

Return Sensor S2 12

GENERAL TROUBLESHOOTING

If the display is showing Error Code 230, either the sensor is bad or a wire is broken. To

check the wire between the input terminals on the circuit board and the sensor itself remove

the circuit board cover and, using the chart above, identify the correct sensor. With a small

screwdriver, loosen the two terminals and gently remove both wires. With an Ohm metor,

check the resistance (continuity) between the two wires. No resistance (continuity) indicates a

wire is broken. The second test is to attach a good sensor to the terminal strip in place of the

one removed. If the display now reads a temperature then the old sensor is probably bad and

should be replaced.

If the display is showing Error Code -40, the wires either have a short or the wires are

reversed at the sensor input terminals. Each sensor has a positive wire and a negative wire

that could have been reversed during installation. To test for this, remove the cover and

reverse the wires. If the display now reads a temperature the problem is solved.

If the display still reads Error Code -40 the wiring between the sensor terminal input and the

sensor itself must be checked for shorts. Remove the wires from the terminal strip and, using

an Ohm meter set at 1K, touch the Ohm motor leads together and adjust the needle to 1. Now

touch the Ohm meter leads to the wires from the sensor. If the needle again goes to 1, or the

and of the scale, the wires are shorted. If the needle only moves part way up the scale, the

sensor is bad and must be replaced.

If you are adjusting a sensor potentiometer R26 through R31, and the display is not changing,

make sure the correct monitor code for the sensor being adjusted has been entered. If the

code is correct and the display still will not change, replace the sensor.

If the sensor has been replaced and the display continues to show the incorrect temperature,

the control panel may be bad. Try a different sensor by switching them around on the terninal

strip. If this still does not work, send the the board back to TRIAD for recalibration.