7 Domestic water heaters (continued)

51

Installation & Service Manual

Minimum Pump Performance

Based on heating potable water with a hardness of 8 to 25

grains per gallon and total dissolved solids not exceeding

350 ppm. See “Water Chemistry”, page 47.

BTU/hr INPUT

GPM Ft. Hd.

90,000 - 500,000 30 8

Remote Sensor Installation

Water heaters are provided with an extra temperature sensor

that MUST BE field installed. The sensor is shipped loose in

the I & O packet. This remote mounted sensor will be the

primary temperature sensor which will inform the appliance’s

built-in thermostat control. For domestic water heating, the

sensor MUST BE installed into a bulbwell on the storage tank.

This is required to maintain the desired temperature in the

tank and reduce cycling of the heater.

The sensor must also be connected to two blue wires provided

in the upper left-hand corner of the control panel. It will be

necessary to add additional wire to reach from the appliance

to the remote water source. Use twisted pair wire, minimum

18 gauge or larger. See Table 5A, page 33 regarding distance

versus wire gauge.

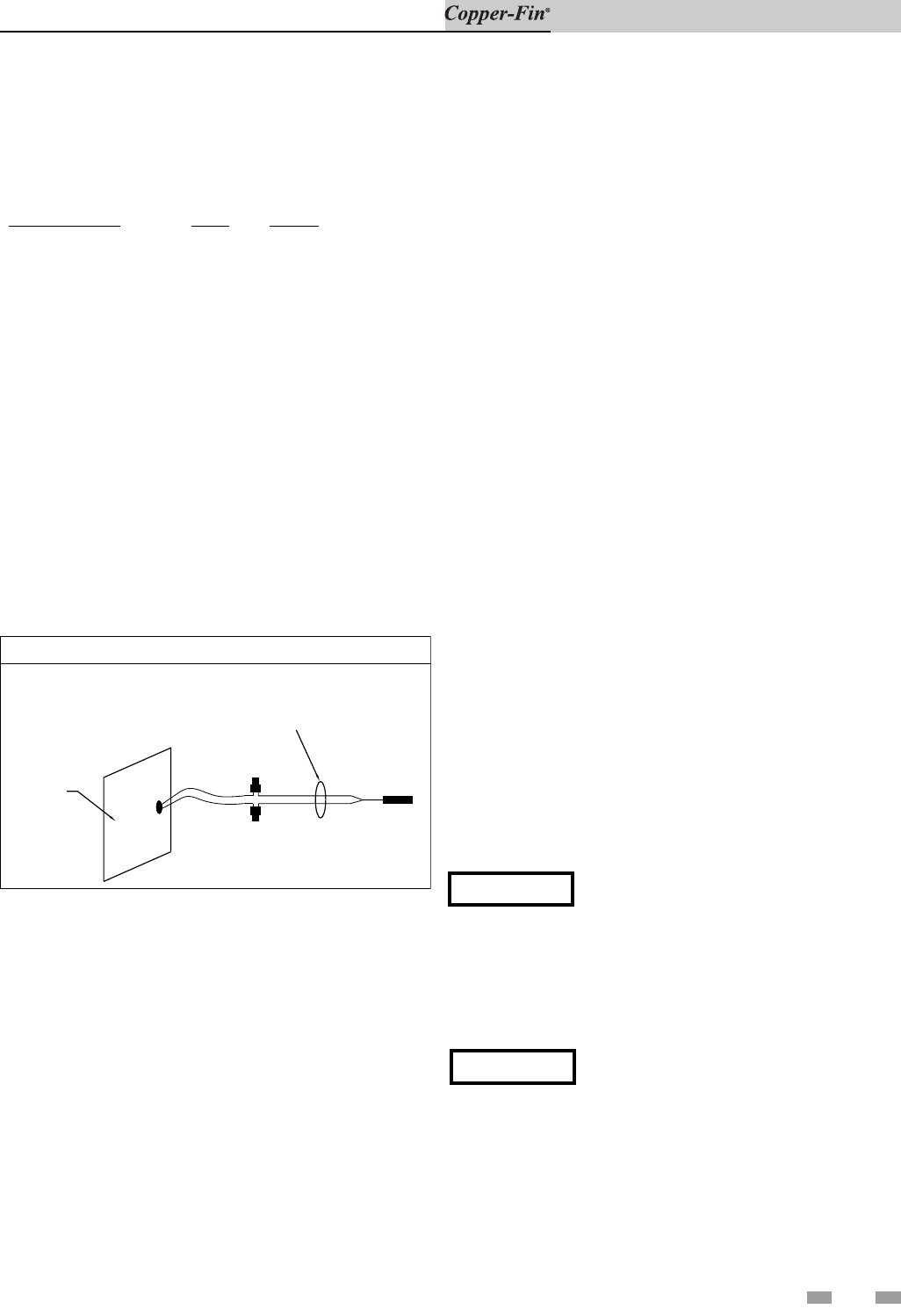

INSTRUCTIONS

EXTERNAL SENSOR FOR TANK, SYSTEM OR PUMP DELAY

REMOTE SENSOR CONNECTOR IS

LOCATED ON SIDE OF UNIT.

NOTE: COLOR OF WIRES AND

LEAD STYLES MAY VARY

WITH SENSOR PROVIDED.

CONNECTIONS ARE POLARITY

INSENSITIVE.

SIDE PANEL

Figure 7-4_External Sensor for Tank, System or Pump

Delay

Heat Exchanger

This is a highly sophisticated heat exchanger, de signed to carry

water in such a way that it gen er ates a scour ing action which

keeps all interior sur fac es free from build-up of impurities. The

straight-line, two pass de sign of the tubes sends water into the

headers at a properly rated velocity. The configuration of the

head ers, in turn, creates a high degree of turbulence which is

sufficient to keep all contaminants in suspension. This

“scouring action” provides greater cost savings for owners.

Tubes are always able to transfer heat at peak ef fi cien cy. Every

surface within this water con tain ing section is of a nonferrous

material, providing clear, clean, rust-free hot water. Straight

copper tubes-finned on the outside for maximum heat transfer

glass lined cast iron one piece cored head ers make up an entirely

rustproof unit. On all mod els, header inspection plugs can be

removed for field in spec tion and cleaning of copper tubes. The

entire heat exchanger may be easily removed from the unit.

Thermostat Settings

1. The thermostat is adjusted to a low test set ting when

shipped from the factory.

2. Set the thermostat to a maximum water temperature of

125°F which will satisfy hot water demands and prevent

risk of scald injury.

Households with small children or invalids may require

120°F or lower temperature setting to re duce risk of scald

in ju ry. Some states may require a lower temperature

setting. Check with your gas supplier for local

re quire ments governing the tem per a ture setting.

Re mem ber, no water heating sys tem will provide exact

tem per a ture at all times. Allow a few days of operation at

this setting to de ter mine the correct temperature set ting

consistent with your needs.

NOTICE

(1) This water heater, when set at the

low er temperature setting, is not capable

of producing hot water of sufficient

temperature for sanitizing pur pos es. (2)

Higher stored water temperature

in creas es the ability of the water heater to

supply desired quantities of hot water,

however remember:

ƽ CAUTION

Hotter water increases the risk of scald

injury.

Incorrect piping of the cold water supply to the sys tem may

result in excessive low temperature op er a tion causing

condensate formation on the heat ex chang er and operational

problems. The cold water supply piping must be installed in the

dis charge piping from the heater to the storage tank. This allows

the cold water to be tempered in the storage tank before entering

the heater. See typ i cal installation drawings provided in this

manual. Higher wa ter temperatures reduce condensate

formation.