46

7 Domestic water heaters

Installation & Service Manual

Domestic Water Heaters 90,000 -

500,000 Btu/hr Models

This section applies only to those units used to sup ply direct

fired domestic hot water and installed with a storage tank(s).

The use of a properly sized pump and the control of water

velocity, as ex plained in the Water Velocity Control section, are

important for correct operation of your hot water heater.

This section contains specific instructions for those units used

to supply domestic hot water. All warn ings, cau tions, notes

and instructions in the gen er al installation and service

sections apply to these instructions. Water heat ers are

designed for installation with a storage tank. The use of a

properly sized pump and the control of water velocity, as

ex plained below, is important for correct operation of your

water heater.

Water Velocity Control

IMPORTANT - To ensure proper velocity through the heat

exchanger, it is necessary to regulate the tem per a ture rise

across the heat exchanger from inlet to outlet. This must be

done on initial in stal la tion and periodically rechecked. With

the correct temperature rise across the heat exchanger, you

may be assured of the proper velocity in the tubes. This will

yield long life and economical operation from your water

heater. Excessive lime build-up in the tube is a result of too

little velocity in the tubes. Excessive pit ting or erosion in the

tube is caused by too much ve loc i ty through the tubes. Care

should be taken to measure tem per a ture rise and maintain a

velocity as follows:

1. The pump must run continuously when the burners are

firing.

2. With the pump running and the water heat er off, the

inlet and outlet ther mom e ters should read the same

temperatures. If they do not, an adjustment must be

made to your final calculation.

3. Turn the water heater on and allow time for the

temperature to stabilize. Record the difference between

the inlet and outlet temperatures. This difference will be

the “tem per a ture rise.”

4. Compare the temperature rise on the heater with the

required temperature rise in Table 7A. Should

adjustment be needed, proceed as fol lows:

If the temperature rise is too high, the water ve loc i ty is too

low. Check the following:

1. Check for restrictions in the outlet of the wa ter heater.

2. Be sure all valves are open between the water heater and

the tank.

3. Check the pump to be sure it is running prop er ly and

that the pump motor is running in the proper direction.

4. Be sure the circulation pipes between the wa ter heater and

storage tank are not less than 2" diameter for a single unit

installation.

5. Common manifold piping for multiple unit in stal la tions

will require larger minimum pipe siz es to tank tappings to

ensure proper flow. See Table 7B on page 47.

6. Multiple unit installations may also require a larger

circulating pump to achieve the specified flow against the

increased head loss of multiple unit com mon manifold

piping.

If the temperature rise is too low, the water ve loc i ty is too high.

Adjust as follows:

1. Slowly throttle the valve on the outlet side of the water

heater until the temperature rise is steady at the required

tem per a ture rise as noted in Table 7A.

2. Sustained high water velocity and low tem per a ture rise

may result in pitting or erosion of the copper tubes in the

heat exchanger. This is a non-warrantable failure.

Temperature rise must be properly adjusted to achieve the

specified flow rate.

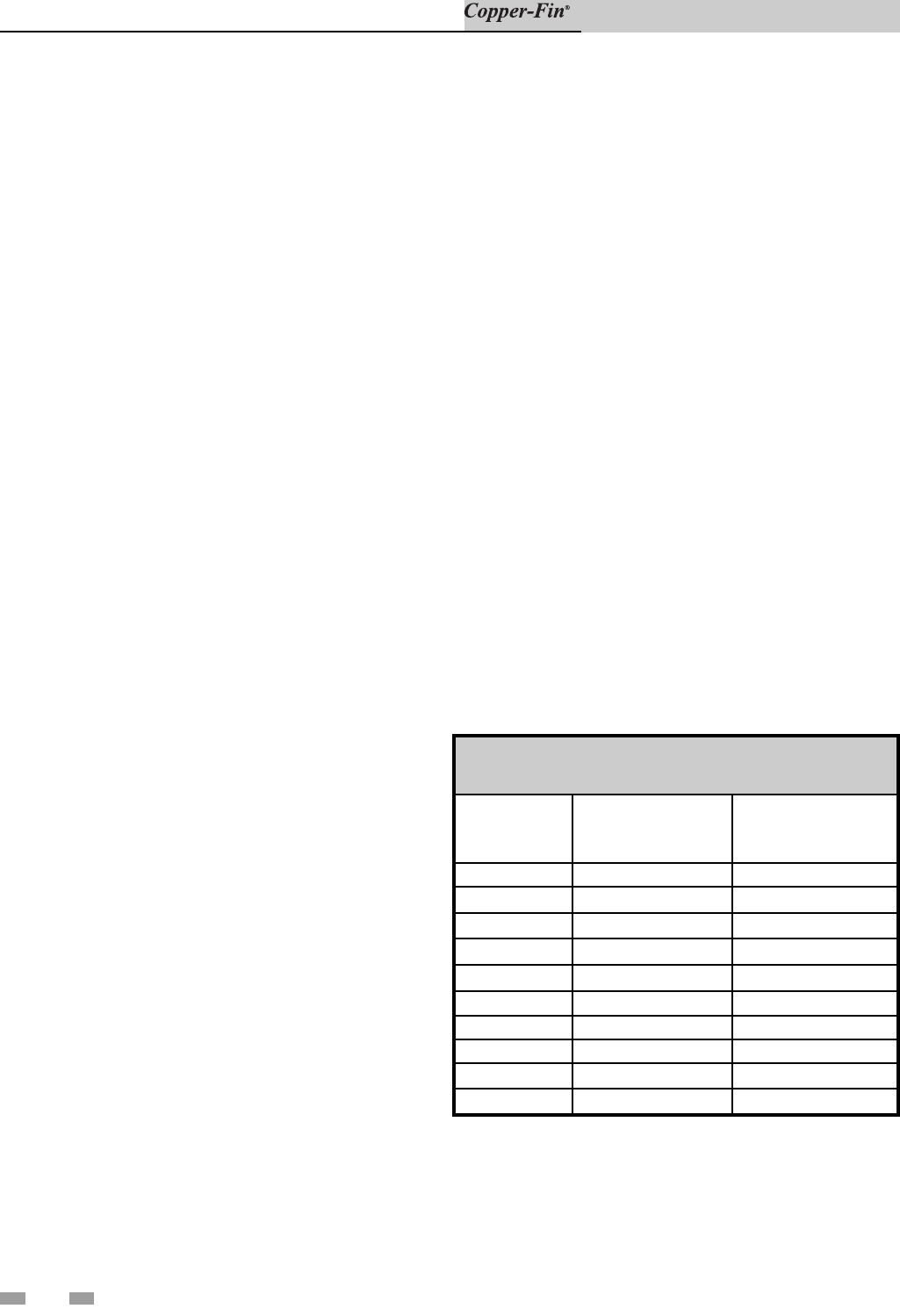

Required Temperature Rise

Temperature rise is based on the hardness of the potable water

to be heated. The temperature rise specified is for water with a

hardness of 5 to 25 grains per gallon. The total dissolved solids

shall not exceed 350 ppm.

TABLE - 7A

REQUIRED TEMPERATURE RISE

Btu/hr

INPUT

Flow Rate

GPM

Temperature Rise °F

90,000 30 5

135,000 30 7

180,000 30 10

199,999 30 11

225,000 30 12

270,000 30 15

315,000 30 17

360,000 30 20

399,999 30 22

500,000 30 28