34

Installation & Service Manual

5 Electrical connections

This appliance is wired for 120 VAC service. The appliance,

when installed, must be electrically ground ed in accordance

with the requirements of the authority having jurisdiction or

in the absence of such re quire ments, with the latest edition of

the National Electrical Code ANSI/NFPA No. 70. When the

unit is in stalled in Canada, it must conform to the CSA C22.1,

Ca na di an Electrical Code, Part 1 and/or local Electrical

Codes.

1. All wiring between the appliance and field

in stalled devices shall be made with type T wire

[63° F(35° C) rise].

2. Line voltage wire exterior to the appliance must be

enclosed in approved conduit or approved metal clad

cable.

3. The pump must run continuously when the appliance is

being fired.

4. To avoid serious damage, DO NOT en er gize the

appliance until the system is full of water. Serious

damage may result.

5. Provide the unit with proper overload protection.

6. Install a wall thermostat on the inside wall. DO NOT

install the thermostat in an area affected by drafts,

sunlight, light fixtures, hot or cold water pipes or near a

fireplace. See “Room Thermostat or Remote Thermostat

Connection to Terminal Strip” (this page), for prop er

wiring con nec tion.

Boiler Operating Temperature Control

The operating temperature control is located in the control

panel, behind the control panel front ac cess door. The sensing

element for the operator is placed in a bulbwell installed in

the heat exchanger. Carefully observe the inlet water

temperature on the initial boiler on cycles. The exact

temperature set point is based on your system’s requirements.

Turn the con trol set point dial to the desired operating water

tem per a ture. Observe the boiler discharge tem per a ture after

each set point adjustment to ensure prop er operation.

Room Thermostat or Remote Thermostat

Connection to Terminal Strip

A room thermostat or remote temperature control may be

connected to the boiler. The room ther mo stat should be

installed on an inside wall, away from the influences of drafts,

hot or cold water pipes, lighting fixtures, televisions, sun rays

or fire plac es. Follow the manufacturers instructions supplied

with the ther mo stat for proper installation and ad just ment.

The boiler is equipped with a terminal strip on the left side of

the control panel to allow easy connection (FIG. 5-1).

Remove the jumper between the R and W terminals on the

terminal strip. Refer to the chart in this section (Table 5A) to

determine maximum allowable length and wire gauge

recommended to connect the switching con tacts of the room

thermostat to the R and W terminals on the terminal strip.

Connection to the terminal strip will allow the room thermostat

to make and break the 24VAC boiler control circuit turning the

boiler on and off based on the room ambient temperature

re quire ments. Set the boiler operating temperature control as

described in this section.

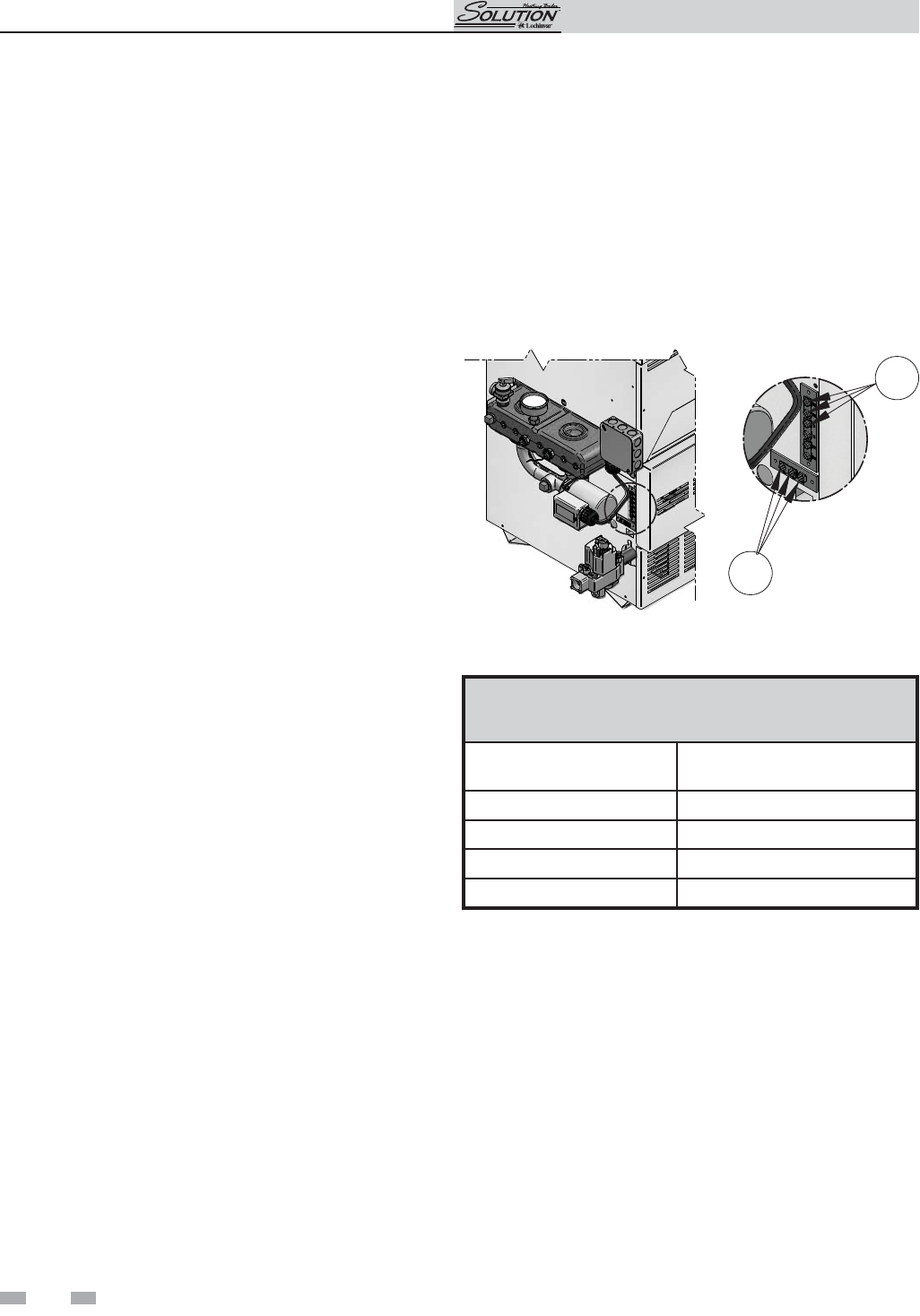

A

B

Figure 5-1_Terminal Strip Connections

Auxiliary Device Connection to Terminal

Strip

A terminal connection strip is provided for ease of connection

for Power Venting Systems, see FIG. 5-1, inset A.

A field supplied powered venter or powered louver/damper may

be connected to the Solution boiler via a terminal strip located

on the left side of the unit, see FIG. 5-1, inset B.

A 24 VAC relay can be powered from this location when a call for

heat has been established. A device proving switch can be

interlocked back to the appliance to ensure its operation before

the appliance is allowed to fire.

Reference the wiring diagram on page 50 of this manual.

TABLE - 5A

TERMINAL STRIP WIRING

Wire Gauge

Allowable Length

Maximum

12 GA 100 ft.

14 GA 75 ft.

16 GA 50 ft.

18 GA 30 ft.