16

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Direct-Vent Retrofit Of Existing Chimney System

An existing Class-A (wood-burning) Metal Chimney or Masonry Chim-

ney can be converted to a direct-vent system. Use one of the following

chimney conversion kits listed below. Have the existing chimney system

inspected by a professional prior to the conversion.

The chimney conversion should not be applied to the portion of the vent

system that is in the room of the appliance. Use only Co-Axial direct-

vent pipe (4” inner pipe, 6 5/8” outer pipe as listed on Page 17) from the

appliance to the retro-connector into converted flue system. Adhere to

all specifications outlined in this manual regarding clearances to combus-

tibles, vertical and horizontal vent length minimums and maximums, etc.

Read all instructions in this manual and provided by vent manufacturer

with kit carefully before starting the installation. Failure to follow the

instructions may create a fire or other safety hazard, and will void the

warranty. The following Vent System components may be safely used

with this appliance.

Figure 17

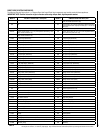

Chimney DV Liner Kits

Model Brand: SECURITY SECURE VENT / Description

SV4MCK Masonry Chimney Conversion Kit –Vertical term. Cap, cap

adapter, masonry cover, black adapter (to flex), 2 gear

clamps

SV4CCK1 Factory Built Chimney Conversion Kit – for 6” I.D., 1” insula-

tion.

SV4CCK2 Factory Built Chimney Conversion Kit – for 7” I.D., 1” insula-

tion; 8” I.D., 1” insulation; 6” I.D., 2” insulation

SV4CCK3 Factory Built Chimney Conversion Kit – for 10” I.D., 1” insula-

tion; 7” I.D., 2” insulation; 8” I.D., 2” insulation

Model Brand: SIMPSON DURA-VENT / Description

934 Masonry Chimney Conversion Kit

931 Factory Built Chimney Conversion Kit A – for 6” I.D.;

932 Factory Built Chimney Conversion Kit B – for 6”, 7” & 8”

I.D.

933 Factory Built Chimney Conversion Kit C – for 7” & 8” I.D.

Table 7

8 feet

1 inch

minimum

Support

Brackets

Wall

Stud

Installing Support Brackets

Install support brackets per vent manufacturers instructions.

Figure 15

Select Venting System - Horizontal Or Vertical

The following sections describe vertical (roof) and horizontal (exterior

wall) vent applications. Refer to the section relating to your instal-

lation. A list of approved venting components is shown on Pages

16 and 17.

Vertical

Horizontal

Combustion

Air

Exhaust

Placement:

Horizontal Runs - Requires a

support bracket every 5 feet

(152 cm).

Vertical Runs - Requires

support brackets every 8

feet (244 cm) above the

stove vent outlet..

Vertical Vent Installation

Support Bracket Placement Diagram

Horizontal Vent Installation

Support Bracket Placement Diagram

Figure 16

Vertical

Rise

Elbow

Horizontal / Inclined Run

(¹⁄₄" Rise per Foot of Horizontal Run in the

Direction away from the Stove)

Termination

Shown

Firestop/Spacer

Vent Sections

Support Bracket Spacing

Every 5 ft (1.52 m)

See figure for

vertical vent

Support

Brackets

Building

Support

Framing

Ceiling

Exterior

Wall

section support.