368261-UIM-A-0508

Johnson Controls Unitary Products 7

BOTTOM RETURN AND ATTIC INSTALLATIONS

Bottom return applications normally pull return air through a base plat-

form or return air plenum. Be sure the return platform structure or return

air plenum is suitable to support the weight of the furnace.

The internal bottom panel must be removed for this application.

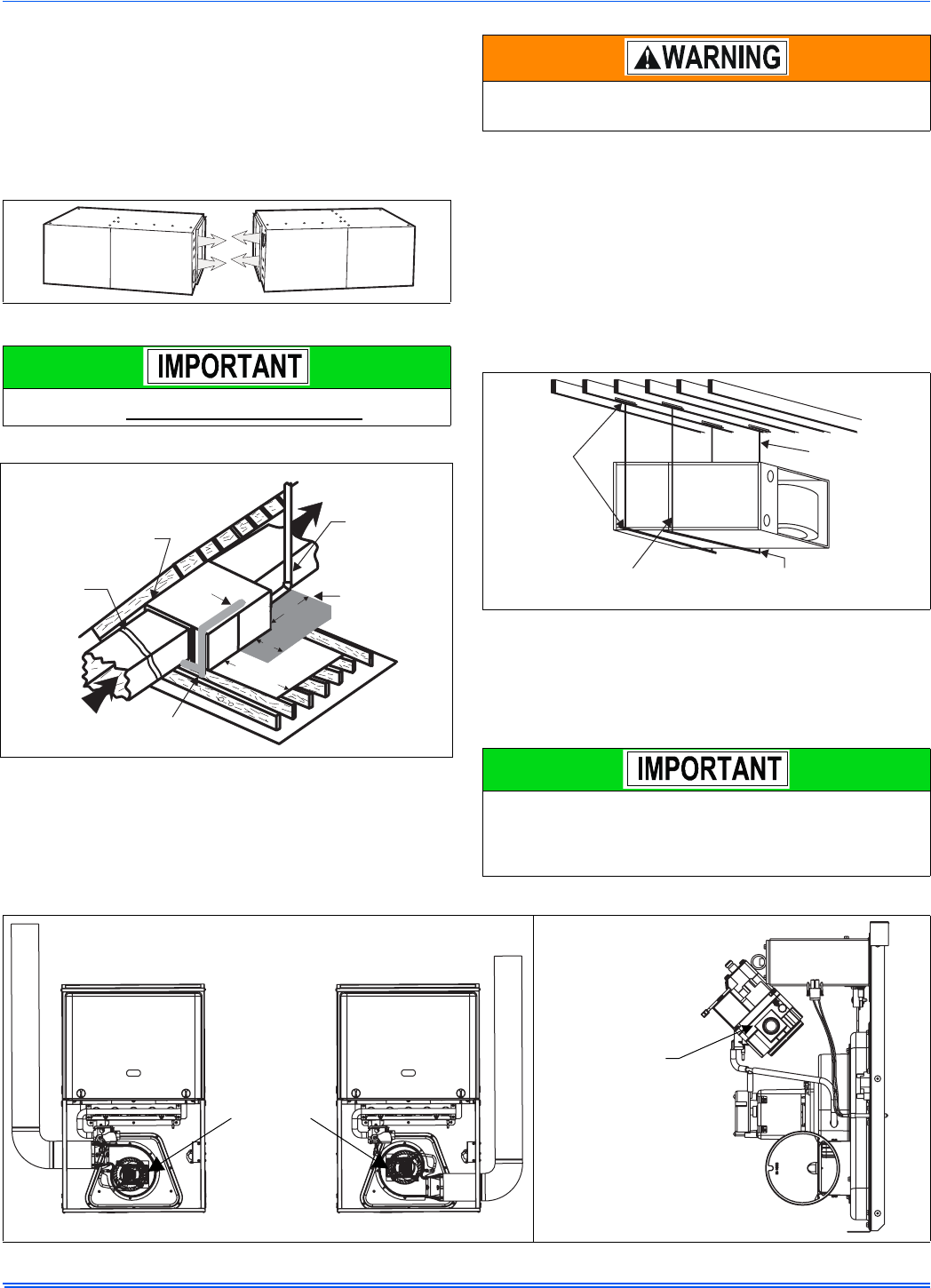

Attic installations must meet all minimum clearances to combustibles

and have floor support with required service accessibility.

HORIZONTAL APPLICATION

ATTIC INSTALLATION

This appliance is certified for line contact when the furnace is installed

in the horizontal left or right position. The line contact is only permissible

between lines that are formed by the intersection of the top and two

sides of the furnace and the building joists, studs or framing. This line

may be in contact with combustible material. Refer to Figure 10, "Typi-

cal Attic Installation".

SUSPENDED FURNACE / CRAWL SPACE

INSTALLATION

The furnace can be hung from floor joists or installed on suitable blocks

or pad. Blocks or pad installations shall provide adequate height to

ensure the unit will not be subject to water damage. Units may also be

suspended from rafters or floor joists using rods, pipe angle supports or

straps. Angle supports should be placed at the supply air end and near

the blower deck. Do not support at return air end of unit. All four sus-

pension points must be level to ensure quite furnace operation. When

suspending the furnace use a secure platform constructed of plywood

or other building material secured to the floor joists. Refer to for typical

crawl space installation.

DOWNFLOW APPLICATION

To apply the furnace in a downflow position, it will be necessary to

rotate the vent blower 90° left or right so that the vent pipe passes

through the side of the furnace casing rather than the end. See Figure

12, "Downflow Venting".

FIGURE 9: Horizontal Application

This furnace may be installed in a horizontal position on either side

as shown above. It must not be installed on its back.

FIGURE 10: Typical Attic Installation

Return

Air

Sediment

Trap

GasPiping

Supply

Air

Vent (Maintain

required

clearances to

combustibles)

Line contact only permissible

between lines formed by the

intersection of furnace top

and two sides and building

joists, studs or framing

12”

30”MIN.

WorkArea

Filter rack

must be a minimum

distance

of 18” (45.7 cm)

from the

furnace

12”

Sheet metal in

front of furnace

combustion air

Openings is

Recommended

When a furnace is installed in an attic or other insulated space,

keep all insulating materials at least 12 inches (30.5 cm) away from

furnace and burner combustion air openings.

FIGURE 11: Typical Suspended Furnace / Crawl Space Installation

For modulating furnaces to be used in the downflow position, it is

necessary to rotate the gas valve so that it is upright when the fur-

nace is installed. Loosen the pipe union between the gas valve and

manifold, rotate the valve as far upward as it will go, and tighten the

union. See Figure 13, "Downflow Installation - Gas Valve Rotation".

Angle Iron

Bracket

6” Min. Between

Rod & Front of Furnace

1” Max. Between

Rod & Back of Furnace

Support

Bracket

FIGURE 12: Downflow Venting FIGURE 13: Downflow Installation - Gas Valve Rotation

LEFT SIDE VENT

RIGHT SIDE VENT

Rotate vent

blower 90°

either way

For downflow

installation,rotate

gas valve upwards,

as shown