368261-UIM-A-0508

6 Johnson Controls Unitary Products

For horizontal left hand applications no conversion is required to an MC

coil when used with a downflow/horizontal furnace. A mounting plate,

supplied with every coil should always be installed on the side desig-

nated as top side. See Figures 4 & 5.

FURNACE ASSEMBLY - PC SERIES COILS

These upflow coils are designed for installation on top of upflow fur-

naces only.

If the coil is used with a furnace of a different size, use a 45° transition

to allow proper air distribution through the coil.

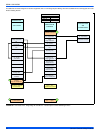

1. Position the coil casing over the furnace opening as shown in Fig-

ure 6, "PC Series Upflow Coil Installation".

2. Place the ductwork over the coil casing flange and secure.

3. Check for air leakage between the furnace and coil casing and

seal appropriately.

NOTE: Dimension “C” should be at least 2/3 of dimension “D”. See Fig-

ure 6, "PC Series Upflow Coil Installation"

CRITICAL COIL PROJECTION

The coil assembly must be located in the duct such that a minimum dis-

tance is maintained between the top of the coil and the top of the duct.

Refer to Table 2, "Coil Projection Dimensions - PC Series Coils".

COIL / FURNACE ASSEMBLY - HC SERIES COILS

These coils are supplied ready to be installed in a right hand position or

a left hand position. When used in conjunction with a horizontal furnace

(blow through) application, the coil should be oriented with the opening

of the “A” coil closest to the furnace. See Figures 7.

NOTE: Each coil is shipped with an external tie plate that should be

used to secure the coil to the furnace. It should be installed on the back

side of the coil using the dimpled pilot holes. See Figures 7.

DOWNFLOW DUCT CONNECTORS

All downflow installations must use a suitable duct connector approved

by the furnace manufacturer for use with this furnace. The duct connec-

tors are designed to be connected to the rectangular duct under the

floor and sealed. Refer to the instructions supplied with the duct con-

nector for proper installation. Refer to the separate accessory parts list

at the end of these instructions for the approved accessory duct con-

nectors.

RESIDENTIAL AND MODULAR HOME UPFLOW

RETURN PLENUM CONNECTION

Return air may enter the furnace through the side(s) or bottom depend-

ing on the type of application. Return air may not be connected into the

rear panel of the unit.

FIGURE 5: Horizontal Left Application

Do not drill any holes or drive any screws into the front duct

flange on the coil in order to prevent damaging coil tubing. See

Figure 6, "PC Series Upflow Coil Installation"

FIGURE 6: PC Series Upflow Coil Installation

Table 2: Coil Projection Dimensions - PC Series Coils

COIL SIZE DIMENSION “C” INCH

PC18 3-1/2

PC24 4-1/2

PC30, PC32, PC35 4-1/2

PC42, PC43, PC36, PC37 5-1/2

PC48 6-1/2

PC60 9

Furnace

Mounting Plate

Flexible

Duct Collar

Do not drill

or Screw

this flange

Field

Fabricated

Ductwork

Upflow

Coil

Upflow

Furnace

Secondary

Drain

Primary

Drain

D

C

(Min)

Alternate

Drain Location

FIGURE 7: Horizontal Left or Right application (Right Shown)

FIGURE 8: Combustible Floor Base Accessory

Use tie plate

supplied with coil

Air flow

Gas Furnace

FURNACE

WARMAIRPLENUM

WITH 1”FLANGES

FIBERGLASS

INSULATION

FIBERGLASSTAPE

UNDER FLANGE

COMBUSTIBLE FLOOR

BASEACCESSORY