368261-UIM-A-0508

18 Johnson Controls Unitary Products

ACCESSORY CONNECTIONS

The furnace control will allow power-switching control of various acces-

sories.

ELECTRONIC AIR CLEANER CONNECTION

Two 1/4” (0.64 cm) spade terminals (EAC and NEUTRAL) for electronic

air cleaner connections are located on the control board. The terminals

provide 115 VAC (1.0 amp maximum) during circulating blower opera-

tion.

HUMIDIFIER CONNECTION

Two 1/4” (0.64 cm) spade terminals (HUM and NEUTRAL) for humidi-

fier connections are located on the control board. The terminals provide

115 VAC (1.0 amp maximum) during heating system operation.

A mounting hole is provided on the control panel next to the furnace

control board for mounting a humidifier transformer if required.

HUMIDISTAT CONNECTION

For better humidity control during cooling operation, an external humi-

distat may be used. When using a external humidistat, put the HUMI-

DISTAT jumper in the “YES” position. Connect the low voltage wiring as

shown in Figures 20-25, Thermostat Charts.

SECTION VI: TWINNING AND STAGING

Twinning and staging is NOT allowed for modulating furnaces.

SECTION VII: VENT SYSTEM

VENT CONNECTIONS

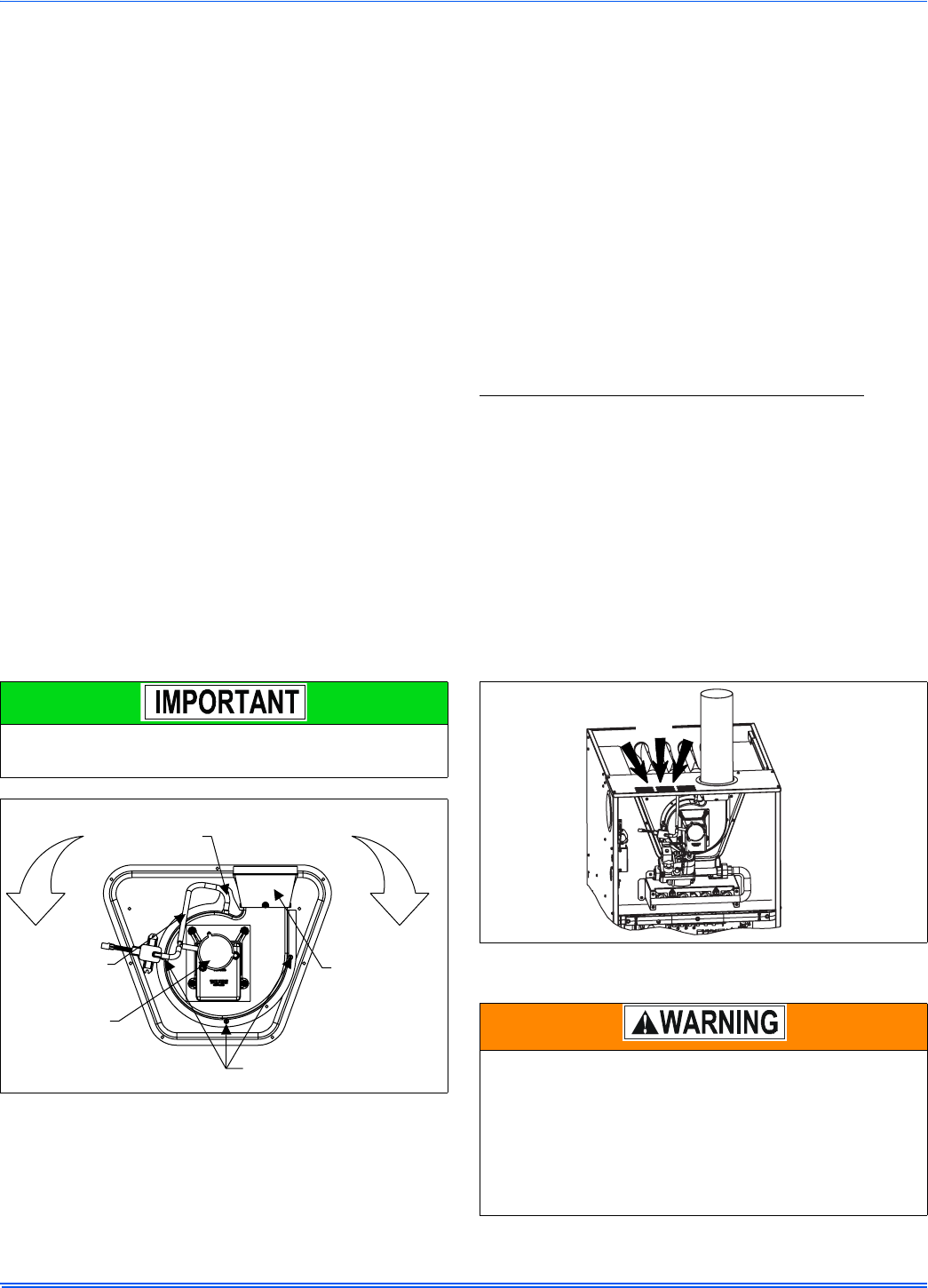

Figure 26, "Combustion Air Inducer" shows the furnace as it is shipped

from the factory. To convert to a horizontal or downflow position, remove

the four screws that secure the inducer assembly and rotate 90° being

careful not to damage the gasket. Reinstall screws. Remove cap from

appropriate vent outlet location on the cabinet cut insulation in cabinet

to same size as the hole provided and reinstall cap in the hole in the top

panel.

CATEGORY 1 - 450 F. MAX. VENT TEMP.

The venting system must be installed in accordance with Section 5.3,

Air for Combustion and Ventilation, of the National Fuel Gas Code

Z223.1/NFPA 54 (latest edition), or Sections 7.2, 7.3 or 7.4 of CSA

B149.1, National Gas and Propane Codes (latest edition) or applicable

provisions of the local building code and these instructions.

The furnace shall be connected to a type B vent connector, and

shall be connected to a type B vent only. The furnace shall not be

connected to a chimney flue serving a separate appliance

designed to burn solid fuel. Single-wall vent pipe is not allowed.

It is recommended that the appliance is installed in a location where the

space temperature is 32 °F (0°C) or higher. If the appliance is installed

in a location where the ambient temperature is below 32 °F (0°C), the

combustion byproducts could condense causing damage to the appli-

ance heat exchanger.

This appliance may be common vented with another gas appliance for

residential installations as allowed by the codes and standards listed in

these instructions.

VENTING

Category I venting consists of vertically venting one or more appliances

in B-vent or B-vent connectors. Type B-vent system extends in a gen-

eral vertical direction and does not contain offsets exceeding 45°. A

vent system having not more than one 60° offset is permitted.

VENTING INTO AN EXISTING CHIMNEY

This furnace may not be connected to any masonry chimney. However,

an existing masonry chimney may be used on as a chase through

which the metal vent pipe passes.

FAN-ASSISTED COMBUSTION SYSTEM

This appliance is equipped with an integral mechanical means to draw

products of combustion through the heat exchanger.

Ambient Combustion Air Supply

This type installation will draw the air required for combustion from

within the space surrounding the appliance and from areas or rooms

adjacent to the space surrounding the appliance. This may be from

within the space in a non-confined location or it may be brought into the

furnace area from outdoors through permanent openings or ducts. A

single, properly sized pipe from the furnace vent connector to the out-

doors must be provided. For upflow models combustion air is brought

into the furnace through the unit top panel opening.

In downflow applications, do not block the combustion air inlet. The

furnace must be installed on a coil cabinet or subbase to allow com-

bustionair to enter the burner compartment.

FIGURE 26: Combustion Air Inducer

COMBUSTION AIR INDUCER

90° 90°

Mounting Screw

(Remove)

Flue Transition

(Do Not Remove

)

Mounting Screw

(Remove)

Pressure

Switch

Pressure Switch

Tube Routing

FIGURE 27: Combustion Airflow Path Through The Furnace Casing to

the Burner Compartment

This type of installation requires that the supply air to the appli-

ance(s) be of a sufficient amount to support all of the appliance(s)

in the area. Operation of a mechanical exhaust, such as an exhaust

fan, kitchen ventilation system, clothes dryer or fireplace may cre-

ate conditions requiring special attention to avoid unsatisfactory

operation of gas appliances. A venting problem or a lack of supply

air will result in a hazardous condition, which can cause the appli-

ance to soot and generate dangerous levels of CARBON MONOX-

IDE, which can lead to serious injury, property damage and / or

death.

COMBUSTION

AIR