8

8. The unit must be connected to the building piping by one

of the following methods:

• Rigid metallic pipe and fittings

• Semirigid metallic tubing and metallic fittings

(Aluminum alloy tubing must not be used in exterior

locations)

• Listed gas appliance connectors used in accordance

with the terms of their listing that are completely in the

same room as the equipment

• In the prior two methods above the connector or tubing

must be protected from physical and thermal damage.

Aluminum alloy tubing and connectors must be coated

to protect against external corrosion when in contact

with masonry, plaster or insulation or are subject to

repeated wettings by liquids (water - not rain water,

detergents or sewage)

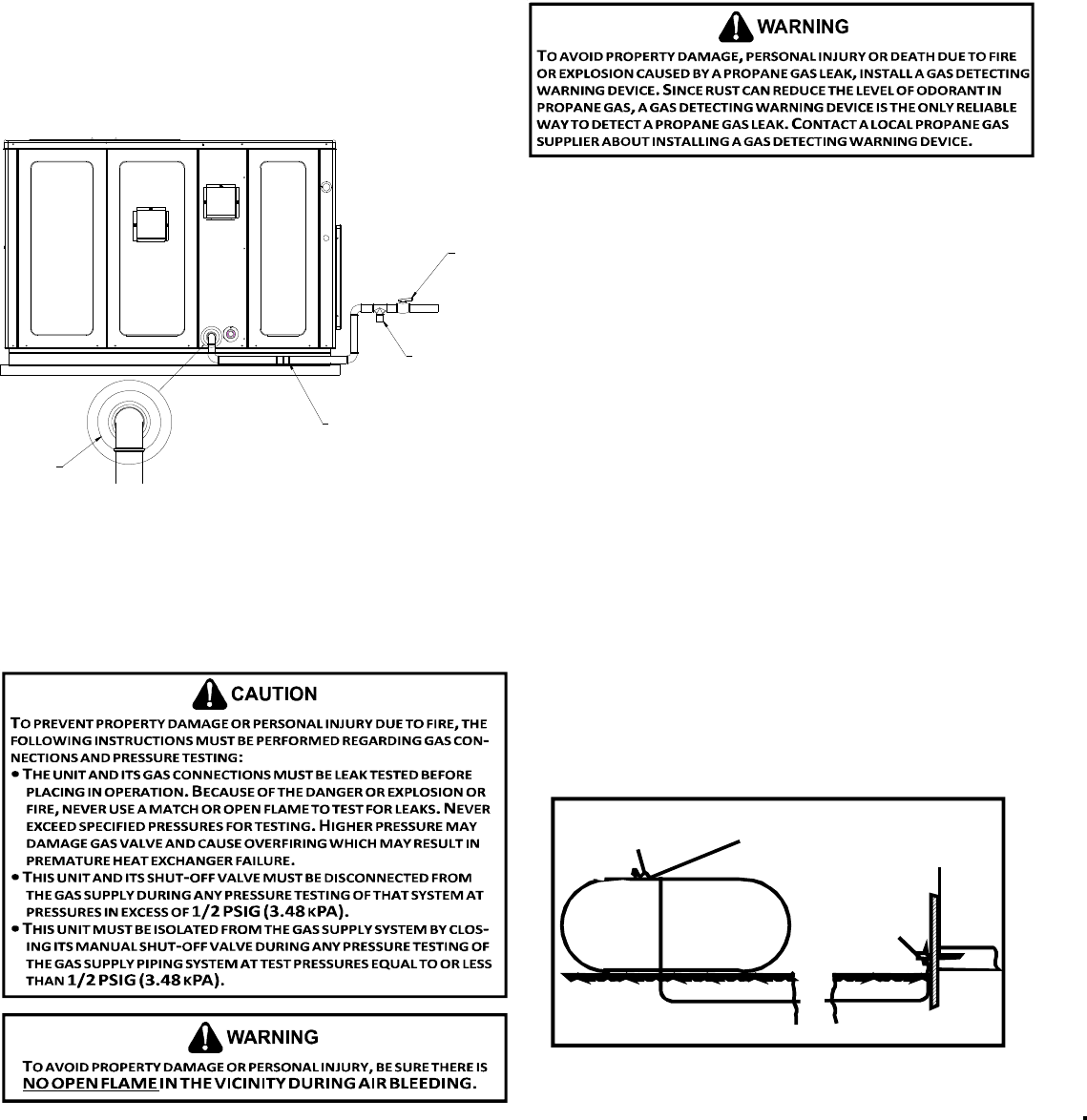

DRIP LEG

MANUAL

SHUT-OFF

VALVE

GROUND JOINT UNION

(INSTALLED AHEAD OF GAS VALVE)

GROMMET

Proper Piping Practice

NOTE: The unit gas supply entrance is factory sealed with

plugs. Keep plugs in place until gas supply is ready to be

installed. Once ready, replace the plugs with the supplied

grommets and install gas supply line.

GAS PIPING CHECKS

There will be air in the gas supply line after testing for leaks

on a new installation. Therefore, the air must be bled from the

line by loosening the ground joint union until pure gas is

expelled. Tighten union and wait for five minutes until all gas

has been dissipated in the air. Be certain there is no open

flame in the vicinity during air bleeding procedure. The unit is

placed in operation by closing the main electrical disconnect

switch for the unit.

PROPANE GAS INSTALLATIONS

IMPORTANT NOTE: Propane gas conversion kits must be

installed to convert units to propane gas. Refer to the gas

piping section for the correct LP kit for conversion.

All propane gas equipment must conform to the safety

standards of the National Board of Fire Underwriters (See

NBFU Manual 58).

For satisfactory operation, propane gas supply pressure must

be within 9.7 - 10.3 inches W.C. at the manifold with all gas

appliances in operation. Maintaining proper gas pressure

depends on three main factors:

1. Vaporization rate, which depends on (a) temperature of

the liquid, and (b) wetted surface area of the container or

containers.

2. Proper pressure regulation.

3. Pressure drop in lines between regulators, and between

second stage regulator and the appliance. Pipe size

required will depend on length of pipe run and total load of

all appliances.

TANKS AND PIPING

Complete information regarding tank sizing for vaporization,

recommended regulator settings and pipe sizing is available

from most regulator manufacturers and propane gas

suppliers.

Since propane gas will quickly dissolve white lead or most

standard commercial compounds, special pipe dope must

be used. Shellac base compounds resistant to the actions of

liquefied petroleum gases such as Gasolac

®

, Stalactic

®

,

Clyde’s

®

or John Crane

®

are satisfactory.

See below for typical propane gas piping.

200 PSIG

Maximum

5 to 15 PSIG

(20 PSIG Max.)

Continuous

11" W.C.

Second Stage

Regulator

First Stage

Regulator

Typical Propane Gas Piping